As a fundamental rule, you should not open a furnace door when its internal temperature is above a critical threshold, often cited as 600°C (1112°F). Opening a furnace at high temperatures introduces severe risks of personal injury from radiant heat and equipment damage from thermal shock. The safest and most recommended procedure is to wait for the furnace to cool down completely before accessing the chamber.

The core principle behind furnace door safety is control. You must control the rapid exchange of heat and atmosphere between the extreme environment inside the furnace and the ambient conditions outside to protect both the operator and the equipment itself.

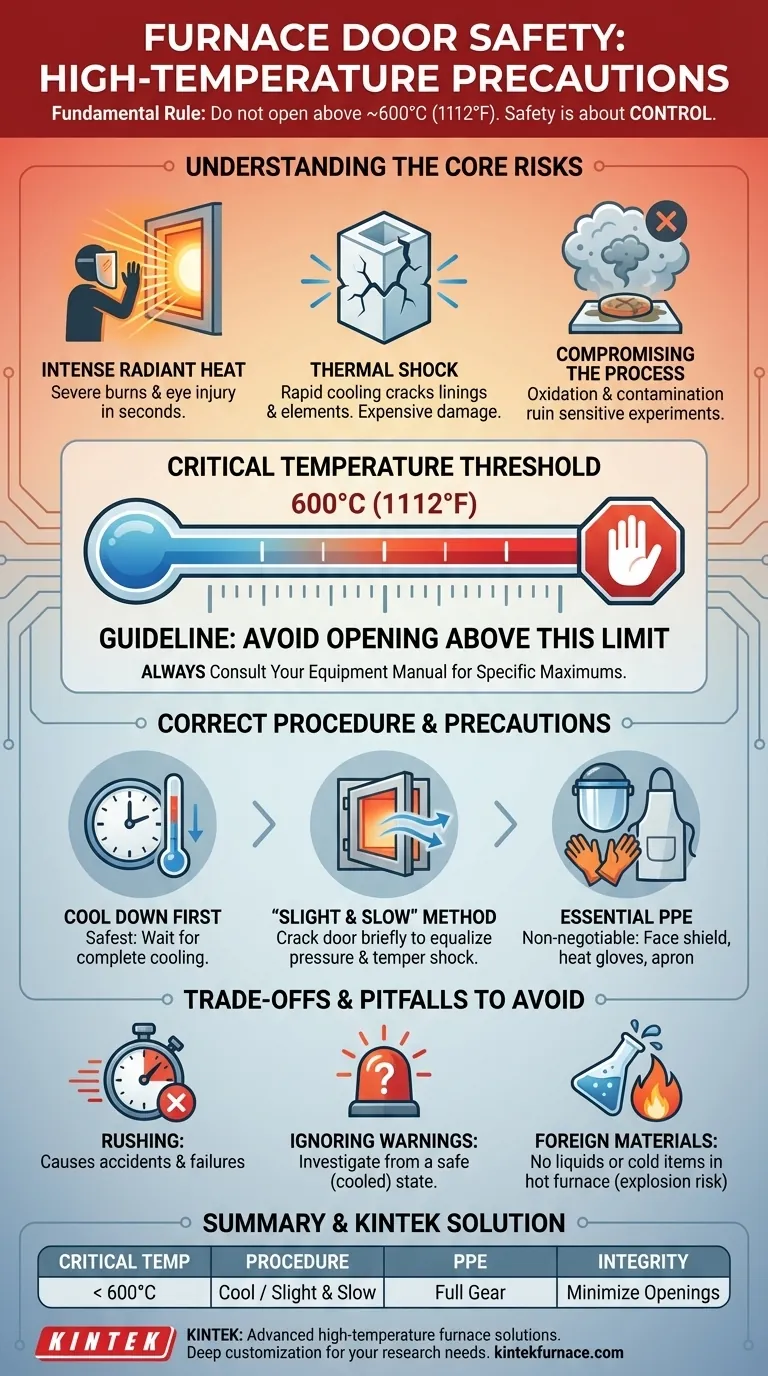

Understanding the Core Risks

When you open a hot furnace door, you are creating a sudden and violent interaction between two vastly different environments. Understanding the specific dangers is the first step toward safe operation.

The Danger of Intense Radiant Heat

Operating a furnace at high temperatures generates immense radiant heat. Opening the door is like opening a direct window to that energy source.

This heat can cause severe burns to exposed skin in seconds, even from a distance. It also poses a significant danger to your eyes, necessitating proper face and eye protection.

The Risk of Thermal Shock

Furnace linings are made of refractory materials (specialized ceramics) designed to withstand high heat but not rapid temperature changes.

When you open the door, cool ambient air rushes in. This creates thermal shock, a rapid contraction of the hot inner surfaces that can cause the lining and heating elements to crack, spall, or fail prematurely, leading to expensive repairs.

Compromising the Process

Many furnace processes rely on a controlled internal environment. Opening the door introduces oxygen and humidity from the outside air.

This can ruin an oxygen-sensitive process, cause unwanted oxidation on your samples, or contaminate a carefully managed inert gas atmosphere.

The Critical Temperature Threshold

While every furnace is different, general guidelines exist to minimize risk.

The 600°C (1112°F) Guideline

The references specify that a furnace door should not be opened above 600°C. This is a common industry guideline for many laboratory and heat-treating furnaces.

Why This Temperature Matters

Above this temperature, the risk of severe thermal shock to the furnace components increases dramatically. The refractory materials are in a more expanded and vulnerable state.

Simultaneously, the intensity of the radiant heat becomes a significant and immediate hazard to the operator.

Always Consult Your Equipment Manual

The 600°C figure is a general rule. Your specific furnace manufacturer will provide the exact maximum temperature for safely opening the door. This specification is the only one you should treat as an absolute rule.

Correct Procedure and Precautions

If you absolutely must open the door while the furnace is hot (and below the manufacturer's specified limit), you must do so with extreme care.

Cool Down Whenever Possible

The default, safest, and most recommended action is to program the furnace to cool down to a safe temperature before opening the door. Patience prevents injury and damage.

The "Slight and Slow" Method

If immediate access is required, do not fling the door open. First, open it just a crack for several moments.

This "slight and slow" technique allows pressure to equalize and a boundary layer of air to temper the immediate thermal shock, protecting the furnace lining. Only after this initial step should you open the door further.

Use Essential Personal Protective Equipment (PPE)

Never approach a hot furnace without appropriate PPE. This is non-negotiable.

Essential gear includes a full face shield (not just safety glasses), heat-resistant gloves (Kevlar or similar), and a heat-resistant apron or jacket.

Understanding the Trade-offs and Pitfalls

Effective furnace operation requires balancing process needs with safety imperatives. Acknowledging common mistakes is critical for avoiding them.

The Pitfall of Rushing

Nearly all furnace-related accidents and equipment failures are rooted in haste. Trying to speed up a cooling cycle or quickly grabbing a sample creates unacceptable risks. A deliberate and patient approach is always safer and more cost-effective.

Ignoring Obvious Warning Signs

If you observe pressure abnormalities, unusual discoloration, or any sign of equipment malfunction, the immediate response should be to stop the process and investigate from a safe state (i.e., after it has cooled). Do not open the door to "check on it."

Introducing Foreign Materials

Never pour liquids or place cold, damp, or volatile materials directly into a hot furnace chamber. The rapid and violent expansion of these materials can cause a small-scale explosion, spattering molten material and damaging the furnace interior.

Making the Right Choice for Your Goal

Your operational procedure should be dictated by your primary goal.

- If your primary focus is maximum safety and equipment longevity: Always wait for the furnace to cool below the manufacturer's specified threshold before opening the door.

- If you must access the chamber at an elevated temperature: Use the "slight and slow" opening method, never exceed the manual's temperature limit, and wear comprehensive heat-protective PPE.

- If your primary focus is process integrity: Minimize any door openings to prevent atmospheric contamination and plan your workflow to consolidate access into a single, well-controlled event.

Operating a high-temperature furnace with deliberate, informed actions ensures both your safety and the integrity of your equipment.

Summary Table:

| Precaution | Key Details |

|---|---|

| Critical Temperature | Do not open above 600°C (1112°F) or manufacturer's limit to avoid thermal shock and radiant heat risks. |

| Cooling Procedure | Wait for furnace to cool completely before access; use 'slight and slow' method if necessary. |

| Personal Protective Equipment (PPE) | Wear full face shield, heat-resistant gloves, and apron to prevent burns and injuries. |

| Process Integrity | Minimize door openings to avoid atmospheric contamination and maintain controlled environments. |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements, enhancing performance and longevity. Contact us today to discuss how we can support your specific needs and deliver tailored solutions for optimal results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation