Proper maintenance of a dental zirconia sintering furnace is a combination of routine operator tasks and periodic professional servicing. The core activities involve regular cleaning of the sintering chamber, ensuring a controlled operating environment, and performing consistent temperature calibrations to guarantee the accuracy and quality of the final restorations.

The reliability of your furnace and the quality of your zirconia restorations depend on more than just following a checklist. True success lies in combining consistent operator-led maintenance with a deep understanding of common operational errors to prevent failures before they happen.

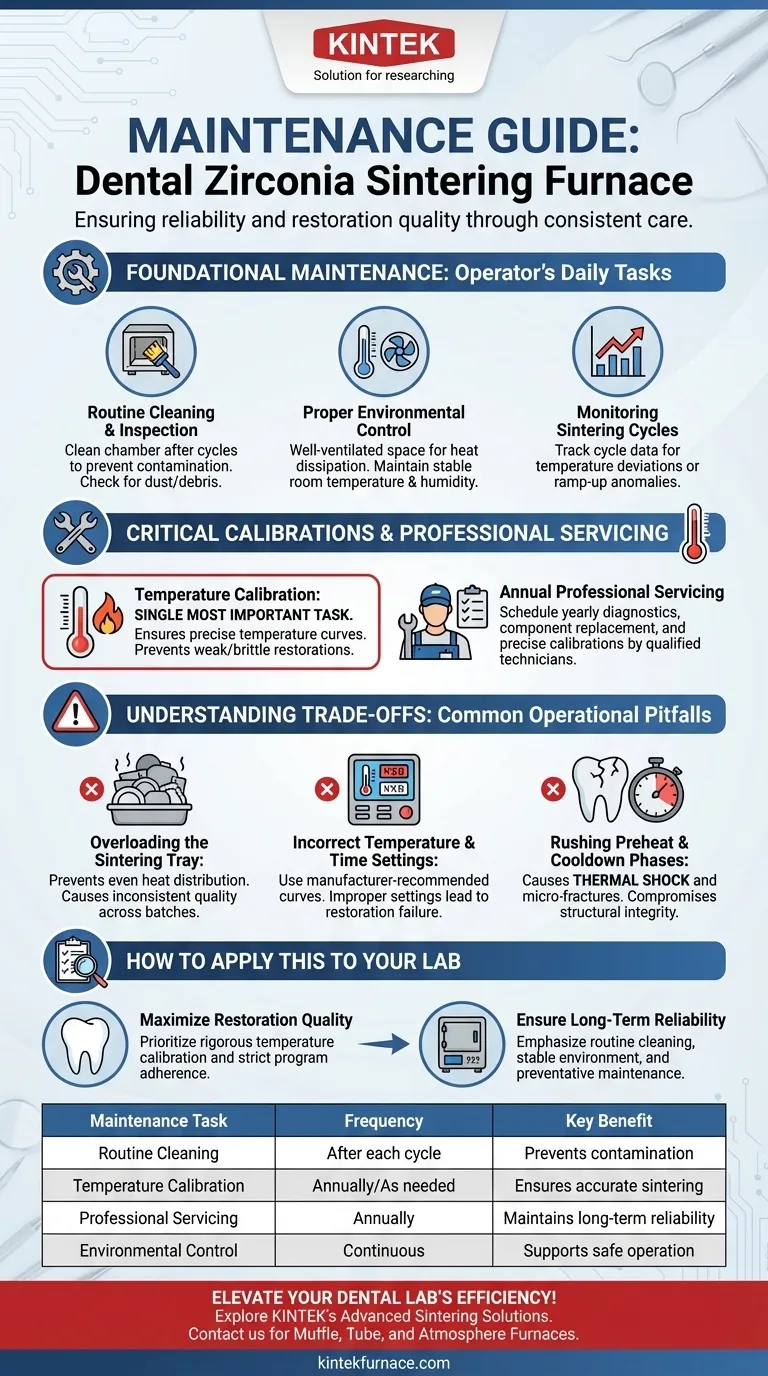

Foundational Maintenance: The Operator's Role

The day-to-day user plays a critical part in the long-term health of the furnace. These routine checks are your first line of defense against inconsistent results and premature equipment wear.

Routine Cleaning and Inspection

The sintering chamber must be kept free of contaminants. After cycles, check for any dust or debris that could interfere with future restorations.

A clean chamber ensures pure sintering conditions, which is vital for achieving the desired translucency and strength in zirconia prosthetics.

Ensuring Proper Environmental Control

Your furnace must operate in a well-ventilated space. This is not only a safety requirement to manage fumes but also helps the equipment dissipate heat effectively, preventing strain on cooling components.

Maintaining a stable room temperature and humidity level also contributes to more predictable and repeatable sintering cycles.

Monitoring Sintering Cycles

Pay close attention to cycle data. Any unexpected deviation in temperature ramp-up times or final hold temperatures can be an early indicator that calibration or servicing is needed.

Consistent monitoring allows you to catch minor issues before they lead to compromised restorations or furnace downtime.

Critical Calibrations and Professional Servicing

While operator tasks are crucial, certain maintenance requires specialized tools and expertise. These actions ensure the core accuracy and integrity of the furnace.

The Importance of Temperature Calibration

Temperature calibration is the single most important maintenance task. Even a slight deviation from the specified temperature curve can dramatically affect the final properties of the zirconia.

Incorrect temperatures can lead to under-sintered, weak restorations or over-sintered, brittle ones. Calibration, performed regularly by a qualified technician, ensures your furnace heats precisely as programmed.

When to Call a Qualified Technician

Beyond troubleshooting, schedule annual professional servicing. A technician will perform comprehensive diagnostics, replace wear-and-tear components, and execute precise calibrations.

This preventative approach is essential for maintaining equipment integrity and ensuring your furnace continues to perform like new, delivering reliable results for years.

Understanding the Trade-offs: Common Operational Pitfalls

Many issues attributed to furnace failure are actually caused by operational errors. Avoiding these common mistakes is as critical as performing routine maintenance.

Overloading the Sintering Tray

Placing too many restorations in the furnace at once prevents even heat distribution. Units in the center may not reach the target temperature, while those on the edge might overheat.

This leads to inconsistent quality across a single batch, undermining the efficiency you were trying to achieve.

Incorrect Temperature and Time Settings

Each zirconia material has a specific, manufacturer-recommended sintering curve. Using incorrect temperature or time settings is a primary cause of restoration failure.

Always double-check that the program selected matches the material being used. Flexible settings are a feature, but they require careful management.

Rushing Preheat and Cooldown Phases

The preheat and cooldown phases are designed to prevent thermal shock, which can cause micro-fractures in the zirconia.

Attempting to shorten these phases to save time is a significant risk that can compromise the structural integrity of the final prosthetic, leading to premature failure in the patient's mouth.

How to Apply This to Your Lab

Your maintenance strategy should align directly with your operational priorities.

- If your primary focus is maximizing restoration quality: Prioritize rigorous temperature calibration and meticulous adherence to manufacturer-specified sintering programs.

- If your primary focus is ensuring long-term equipment reliability: Emphasize routine cleaning, a stable operating environment, and adhering to a strict schedule of professional preventative maintenance.

Ultimately, viewing maintenance as an investment in predictable outcomes is the key to protecting your equipment and your reputation.

Summary Table:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Routine Cleaning | After each cycle | Prevents contamination for consistent results |

| Temperature Calibration | Annually or as needed | Ensures accurate sintering for restoration quality |

| Professional Servicing | Annually | Maintains long-term reliability and performance |

| Environmental Control | Continuous | Supports safe operation and heat dissipation |

Elevate your dental lab's efficiency and restoration quality with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, and Vacuum & Atmosphere Furnaces, tailored to your unique needs through deep customization. Whether you're focused on maximizing quality or ensuring equipment longevity, our expertise can help. Contact us today to discuss how our products can benefit your lab!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity