In essence, vacuum carburizing is a modern case-hardening process that creates an exceptionally hard, wear-resistant surface on steel components. It is performed inside a vacuum chamber by heating the parts and introducing a carbon-rich gas, like acetylene, at very low pressure. This allows carbon atoms to diffuse into the steel's surface, forming a hardened "case" while the interior "core" remains soft and tough.

By removing oxygen from the equation, vacuum carburizing delivers superior metallurgical quality and unprecedented process control, resulting in cleaner, stronger, and more consistent components compared to traditional atmospheric methods.

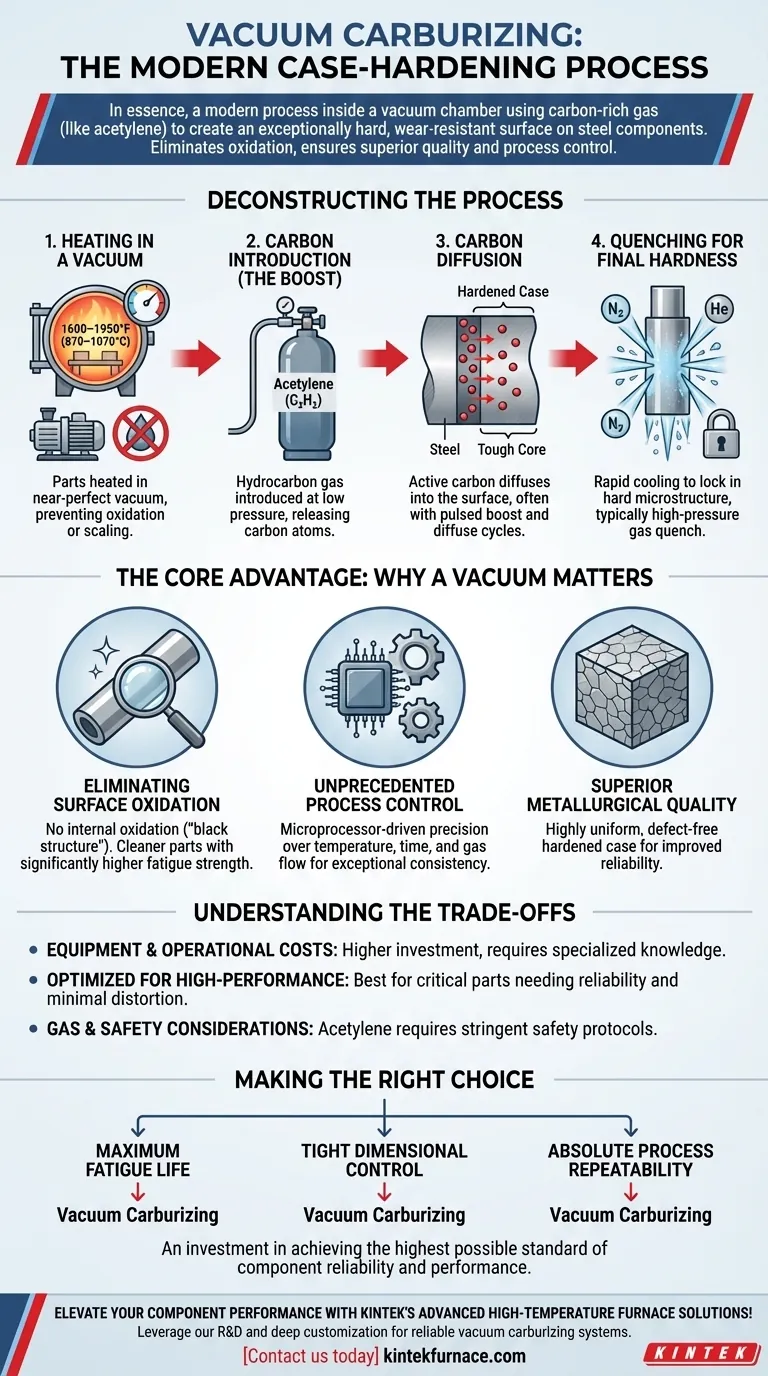

Deconstructing the Vacuum Carburizing Process

The process, also known as Low Pressure Carburizing (LPC), is a precisely controlled sequence of heating, carbon enrichment, and quenching. Each step is optimized to achieve the desired surface hardness and case depth.

Step 1: Heating in a Vacuum

First, the steel parts are loaded into a sealed furnace and the chamber is pumped down to a near-perfect vacuum. The parts are then heated to a high temperature, typically between 1600–1950°F (870–1070°C). The vacuum prevents any oxidation or scaling from forming on the part's surface.

Step 2: Carbon Introduction (The "Boost")

Once at temperature, a hydrocarbon gas—most commonly **acetylene (C₂H₂) **—is introduced into the chamber at a very low pressure. The intense heat causes the acetylene molecules to break down, releasing carbon atoms directly onto the hot steel surfaces.

Step 3: Carbon Diffusion

The highly active carbon atoms are absorbed and begin to diffuse into the surface of the steel. This is often performed in a "boost and diffuse" cycle, where the gas is alternately introduced and then shut off. This pulsed approach allows the absorbed carbon to penetrate deeper into the material, ensuring a more uniform case depth.

Step 4: Quenching for Final Hardness

After the desired case depth is achieved, the parts must be cooled rapidly, or quenched, to lock in the hard, carbon-rich microstructure. This is typically done with a high-pressure gas quench (HPGQ) using inert gases like nitrogen or helium, or in some cases, with a traditional oil quench.

The Core Advantage: Why a Vacuum Matters

The use of a vacuum is not incidental; it is the key differentiator that provides the process with its most significant benefits. It fundamentally changes the environment in which the steel is treated.

Eliminating Surface Oxidation

Traditional carburizing happens in an atmosphere containing oxygen. This leads to surface scale and, more damagingly, internal oxidation that creates a "black structure" just below the surface. A vacuum eliminates this entirely, resulting in parts that are metallurgically clean, require no post-process cleaning, and exhibit significantly higher fatigue strength.

Unprecedented Process Control

The entire process is managed by microprocessors that precisely control temperature, time, and gas flow. This removes process variables common in atmospheric furnaces, leading to exceptional repeatability and consistency from one batch to the next. The results are predictable and conform to stringent quality standards like CQI-9.

Superior Metallurgical Quality

The result of this control is a highly uniform and homogeneous hardened case. Without the detrimental effects of oxidation, the component's surface is free of defects, improving its reliability and service life under demanding conditions.

Understanding the Trade-offs

While vacuum carburizing offers state-of-the-art results, it is essential to understand its context within manufacturing.

Equipment and Operational Costs

Vacuum furnaces are sophisticated and represent a higher initial capital investment than traditional atmospheric furnaces. The precision controls and vacuum systems also require specialized knowledge for operation and maintenance.

Optimized for High-Performance Needs

The superior quality and consistency come at a cost that may not be justifiable for all components. The process is best suited for critical parts where performance, reliability, and minimal distortion are paramount. For less demanding applications, conventional methods may be more cost-effective.

Gas and Safety Considerations

Acetylene is an extremely effective source of carbon, but it is also a highly reactive gas that requires stringent safety protocols for storage and handling.

Making the Right Choice for Your Components

Choosing a heat treatment process requires aligning its capabilities with your component's specific performance requirements.

- If your primary focus is maximum fatigue life and performance: Vacuum carburizing is the definitive choice due to the clean, oxidation-free surface it produces.

- If your primary focus is tight dimensional control and minimizing distortion: The uniform heating and controlled gas quenching offer significant advantages over harsher liquid quenches.

- If your primary focus is absolute process repeatability for critical parts: The precise, microprocessor-driven nature of vacuum carburizing ensures unparalleled consistency batch after batch.

Ultimately, adopting vacuum carburizing is an investment in achieving the highest possible standard of component reliability and performance.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Modern case-hardening in a vacuum chamber using carbon-rich gas like acetylene |

| Key Steps | Heating in vacuum, carbon introduction, diffusion, and quenching (e.g., gas or oil) |

| Advantages | No oxidation, superior metallurgical quality, precise control, high repeatability, and clean surfaces |

| Best For | High-performance components requiring maximum fatigue life, minimal distortion, and consistent quality |

| Considerations | Higher equipment costs, specialized operation, and safety protocols for gases like acetylene |

Elevate your component performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum carburizing systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering cleaner, stronger, and more consistent results. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density