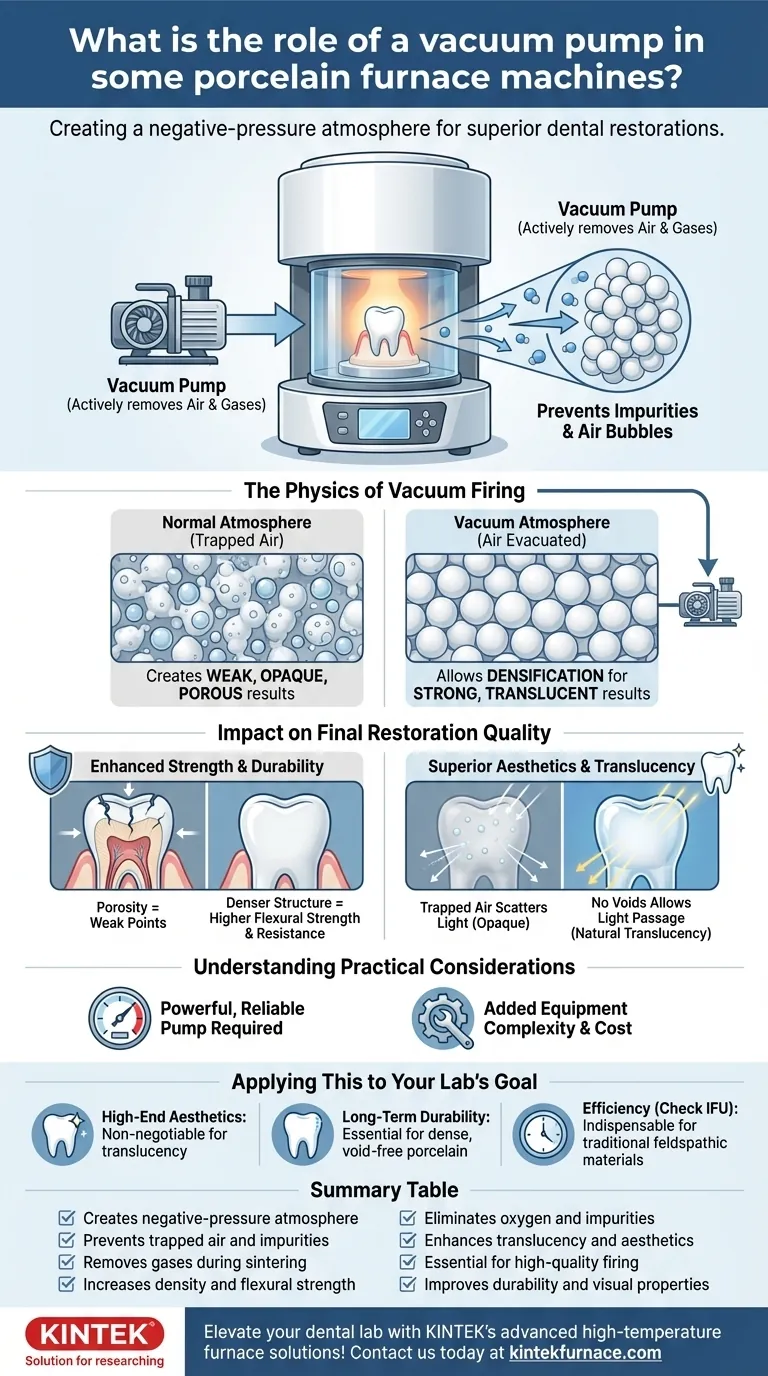

In a modern porcelain furnace, the vacuum pump's role is to create a negative-pressure atmosphere within the firing chamber. By actively removing air and other gases during the sintering cycle, the pump prevents impurities and air bubbles from becoming trapped within the ceramic. This process is fundamental to producing dense, strong, and aesthetically superior dental restorations.

The core problem in firing porcelain is trapped air, which creates weak, opaque, and porous results. A vacuum pump solves this by removing the air before the porcelain fuses, fundamentally improving the material's final density, strength, and visual properties.

The Physics of Vacuum Firing

The inclusion of a vacuum system elevates a simple oven into a precision instrument. Understanding how it works reveals why it is not an optional feature for high-quality work, but an essential one.

Eliminating Trapped Air and Porosity

Porcelain is made of fine particles. As these particles are heated, they begin to fuse together in a process called sintering.

In a normal atmosphere, air gets trapped in the microscopic spaces between these fusing particles. This creates voids, or porosity, within the final restoration, acting as internal weak points.

How the Vacuum Phase Works

A vacuum-capable furnace engages the pump at a specific point in the firing cycle, typically as the temperature rises but before the porcelain reaches its final vitrification (glazing) point.

The pump evacuates the air from the firing chamber, or muffle. This allows the porcelain particles to coalesce and densify in a near-airless environment, minimizing the formation of internal voids.

Preventing Oxidation and Impurities

Removing the air also removes oxygen and other atmospheric gases. This prevents unwanted chemical reactions that can cause discoloration or opacity in the final ceramic.

By firing in a controlled vacuum, you ensure the material's chemistry remains pure, allowing its intended optical properties to emerge.

Impact on Final Restoration Quality

The use of a vacuum directly translates to measurable improvements in the clinical performance and appearance of the final crown, veneer, or bridge.

Enhanced Strength and Durability

A restoration with less porosity is a denser, more homogenous restoration. This directly increases its flexural strength and resistance to fracture.

Fewer internal voids mean there are fewer starting points for cracks to propagate under the stress of chewing, leading to a more durable and long-lasting result.

Superior Aesthetics and Translucency

This is perhaps the most visible benefit. Trapped air bubbles scatter light, making porcelain appear cloudy, flat, and opaque.

By removing these voids, the vacuum firing process allows light to pass through the material more naturally. This creates the depth, translucency, and vitality that mimics natural tooth enamel.

Understanding the Practical Considerations

While essential for quality, incorporating a vacuum system introduces factors that every technician and lab owner must manage.

The Need for a Powerful, Reliable Pump

Not all vacuum pumps are created equal. A furnace needs a pump powerful enough to achieve and hold a specific level of vacuum (measured in inches of mercury or bar).

A weak or failing pump will not remove enough air, negating the benefits and producing compromised results. Regular maintenance and performance checks are critical.

Added Equipment Complexity and Cost

Furnaces equipped with vacuum systems are inherently more complex and costly than simple atmospheric ovens.

The pump and its associated plumbing are additional points of potential failure that require monitoring and service over the life of the equipment.

Applying This to Your Lab's Goal

Your decision to use or prioritize a vacuum furnace should be guided by the type of work you aim to produce.

- If your primary focus is high-end aesthetic restorations: A furnace with a high-performance vacuum system is non-negotiable for achieving the translucency and vitality required for anterior cases.

- If your primary focus is long-term durability: The vacuum is essential for creating dense, void-free porcelain that can withstand occlusal forces, especially in posterior restorations and bridge substructures.

- If your primary focus is maximizing efficiency for certain materials: While indispensable for traditional feldspathic porcelains, always consult the instructions for use (IFU) for modern monolithic ceramics, as some may have unique firing requirements.

Ultimately, mastering the vacuum phase is essential for controlling the final outcome of your ceramic restorations.

Summary Table:

| Role of Vacuum Pump | Key Benefits |

|---|---|

| Creates negative-pressure atmosphere | Prevents trapped air and impurities |

| Removes gases during sintering | Increases density and flexural strength |

| Eliminates oxygen and impurities | Enhances translucency and aesthetics |

| Essential for high-quality firing | Improves durability and visual properties |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, helping you achieve superior dental restorations with enhanced strength and aesthetics. Contact us today to discuss how our tailored solutions can benefit your workflow!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab