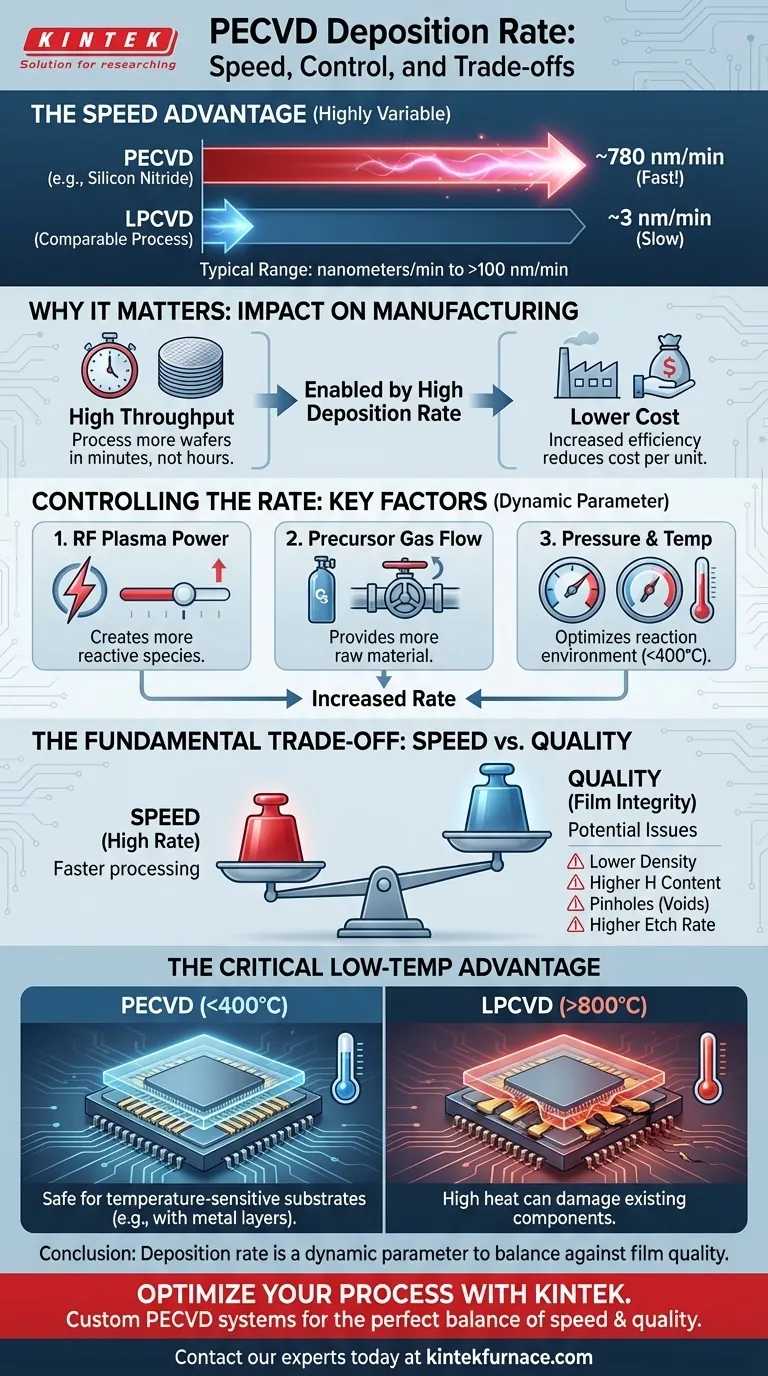

Ultimately, the deposition rate of PECVD is not a single number but a highly variable parameter, typically ranging from a few nanometers to well over a hundred nanometers per minute. For example, a common process for silicon nitride can achieve rates of around 780 nm/min (130 Å/sec), which is dramatically faster than the ~3 nm/min (~48 Å/min) seen in a comparable Low-Pressure CVD (LPCVD) process. This high rate is a primary reason for its widespread adoption in manufacturing.

The core takeaway is that PECVD's high deposition rate is its key advantage, but only when understood in context. It enables high throughput at low temperatures, a critical capability for modern electronics, but this speed is a direct trade-off against film quality and must be carefully managed.

Why Deposition Rate is a Decisive Factor

The deposition rate is more than just a performance metric; it directly influences manufacturing cost, throughput, and the feasibility of a fabrication process.

The Impact on Throughput and Cost

A higher deposition rate means a thin film can be deposited in minutes rather than hours. This drastically increases the number of wafers or substrates that can be processed in a given time.

This enhanced efficiency reduces manufacturing costs per unit and increases overall production capacity, making PECVD a highly cost-effective solution for high-volume production.

The Context of "Fast": PECVD vs. Other Methods

When comparing deposition methods, context is everything. PECVD is renowned for being significantly faster than LPCVD (Low-Pressure Chemical Vapor Deposition). LPCVD often produces higher-purity, more conformal films, but its low deposition rate is a major bottleneck.

However, PECVD may not always be faster than all "CVD" variants. Some high-temperature Atmospheric Pressure CVD (APCVD) processes can achieve very high rates. The unique advantage of PECVD is achieving high deposition rates at low temperatures (typically below 400°C).

Key Factors Controlling Deposition Rate

The deposition rate in a PECVD system is not fixed. It is a dynamic parameter that can be tuned by adjusting several process variables.

RF Plasma Power

Increasing the radio frequency (RF) power supplied to the electrodes energizes the plasma. This creates a higher concentration of free radicals and reactive species from the precursor gas.

More reactive species lead directly to a faster deposition rate. However, this effect has a limit. Once the precursor gas is fully ionized, further increases in power will not increase the rate and may negatively impact the film through excessive ion bombardment.

Precursor Gas Flow Rate

The flow rate of the precursor gas into the chamber determines the availability of reactant molecules. Increasing the gas flow provides more raw material for the plasma to convert into film.

This directly contributes to a faster rate of film formation, assuming the RF power is sufficient to dissociate the additional gas.

Chamber Pressure and Temperature

Process pressure, typically in the range of 0.1 to 40 Pascals, influences the density of the plasma and the mean free path of particles. Adjusting pressure is a key part of optimizing the reaction environment for a desired rate and film quality.

While PECVD is a "low-temperature" process, temperature still affects the surface mobility of deposited atoms and the efficiency of surface chemical reactions, thereby influencing the final film structure and, to a lesser extent, the rate.

Understanding the Trade-offs: Speed vs. Quality

The high deposition rate of PECVD does not come for free. It involves a fundamental trade-off between manufacturing speed and the resulting film's quality.

Film Density and Hydrogen Content

Because the deposition occurs quickly and at low temperatures, atoms have less time and energy to settle into a dense, ordered structure. This often results in films with lower density compared to those from high-temperature processes like LPCVD.

Furthermore, hydrogen-containing precursor gases (like silane, SiH₄) are common. The rapid process can trap hydrogen within the film, which can affect its electrical and mechanical properties.

Pinhole Defects and Etch Rate

The rapid, less-ordered growth can lead to a higher incidence of microscopic voids or pinholes, especially in thinner films.

These lower-density films also tend to have a higher wet etch rate. This is a key indicator that the film is less robust than a comparable film grown slowly at high temperature.

The Critical Low-Temperature Advantage

These trade-offs are acceptable because of PECVD's primary benefit: it works at low temperatures. This allows for the deposition of films on top of substrates that have already been patterned with metal layers or other temperature-sensitive components, which would be destroyed by the high temperatures of LPCVD (often >800°C).

Making the Right Choice for Your Goal

Your approach to PECVD should be dictated by your end goal. The deposition rate is a powerful lever to be adjusted according to your specific priorities.

- If your primary focus is maximum throughput at low temperatures: PECVD is the ideal choice. You should optimize RF power and gas flow to achieve the highest possible deposition rate for your material.

- If your primary focus is the highest possible film purity and density: You should consider a high-temperature alternative like LPCVD, but you must accept the significantly lower deposition rate and ensure your substrate can withstand the heat.

- If your primary focus is a balance of speed and quality: You will need to carefully tune your PECVD process, recognizing that pushing for the absolute maximum rate will likely compromise film integrity.

Mastering PECVD means treating its deposition rate not as a fixed value, but as a dynamic parameter to be balanced against your specific film quality and manufacturing requirements.

Summary Table:

| Factor | Effect on Deposition Rate | Typical Range/Impact |

|---|---|---|

| RF Plasma Power | Increases rate by creating more reactive species | Critical up to a saturation point |

| Precursor Gas Flow | Higher flow provides more raw material, increasing rate | Directly proportional to available reactants |

| Process Pressure | Optimizes plasma density and reaction environment | 0.1 - 40 Pascals |

| Process Temperature | Minor influence on rate; major impact on film structure | Typically < 400°C |

| Trade-off: Film Quality | Higher rates can lower density, increase hydrogen content & etch rate | Speed vs. quality balance is key |

Need to optimize your PECVD process for the perfect balance of speed and film quality?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced PECVD and CVD systems tailored to your unique requirements. Whether your priority is maximum throughput for high-volume production or achieving specific film properties, our deep customization capabilities ensure your furnace solution is precisely engineered for your success.

Let's discuss your application. Contact our experts today to explore how our PECVD systems can enhance your manufacturing process.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication