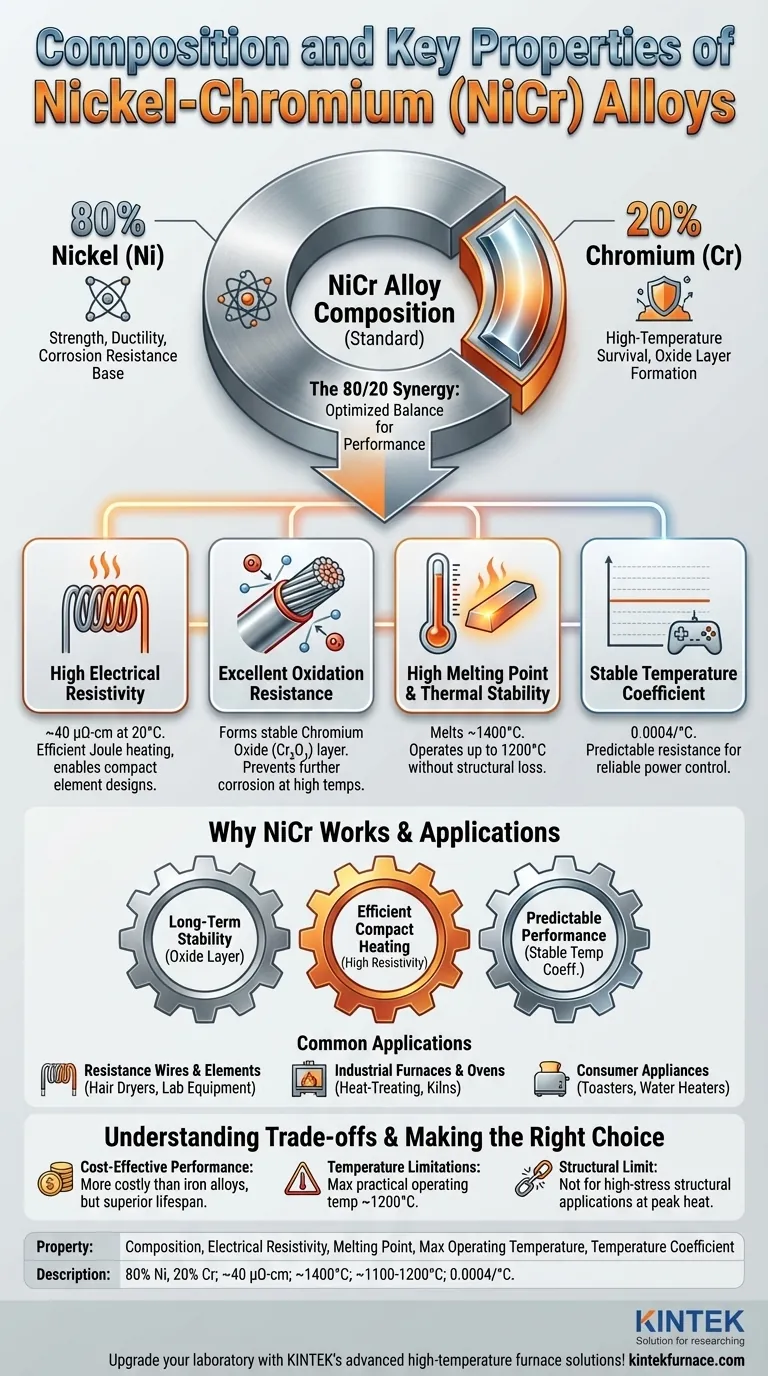

At its core, a Nickel-Chromium (NiCr) alloy is a simple mixture, most commonly composed of 80% nickel and 20% chromium. This specific composition gives it a unique set of properties, including high electrical resistance, a high melting point of 1400°C, and exceptional resistance to oxidation at high temperatures. These characteristics make it the industry standard for electrical heating elements.

The true value of NiCr isn't just one property, but the synergy between them. Its high resistance allows it to generate heat efficiently, while its ability to form a protective oxide layer ensures it doesn't destroy itself in the process, leading to a long and reliable service life.

The Core Properties Explained

To understand why NiCr is so widely used, we must look at how its individual properties contribute to its primary function: converting electricity into heat reliably and over a long period.

High Electrical Resistivity

NiCr has a relatively high electrical resistivity (approximately 40 μΩ-cm at 20°C). When current flows through a material with high resistance, it generates significant heat (Joule heating).

This property means that a shorter length of NiCr wire can produce the same amount of heat as a much longer length of a less resistive material like copper, making it ideal for compact heating element designs.

Excellent Oxidation Resistance

This is arguably NiCr's most critical property. When heated, the chromium in the alloy reacts with oxygen in the air to form a very thin, stable, and adherent layer of chromium oxide (Cr₂O₃) on its surface.

This passive oxide layer acts as a protective barrier, preventing oxygen from reaching the metal underneath. It effectively stops further oxidation and corrosion, even at extreme temperatures, which is why NiCr heating elements don't simply burn away.

High Melting Point & Thermal Stability

With a melting point of around 1400°C, NiCr can operate at very high temperatures without losing its structural integrity.

This allows it to glow red-hot in applications like toasters, furnaces, and ovens while maintaining its mechanical strength and shape, ensuring a long operational lifespan.

Stable Temperature Coefficient

NiCr has a low and stable temperature coefficient of resistance (0.0004/°C). This means its electrical resistance does not change drastically as its temperature increases.

This predictability is vital for designing control systems. Engineers can reliably calculate the power output and temperature of a heating element without worrying about unpredictable resistance fluctuations.

Why This Composition Works: The 80/20 Synergy

The standard 80/20 ratio is not arbitrary; it represents a carefully optimized balance between the properties of nickel and chromium.

The Role of Nickel (80%)

Nickel forms the bulk of the alloy, providing ductility and strength. It allows the alloy to be easily drawn into the thin wires required for heating elements without becoming brittle. Nickel also has good inherent corrosion resistance, providing a solid foundation for the alloy.

The Role of Chromium (20%)

Chromium is the key to high-temperature survival. It is the element responsible for forming the protective chromium oxide layer that gives the alloy its signature resistance to oxidation and scaling.

Common Applications and Use Cases

The unique combination of properties makes NiCr the go-to material for a wide range of resistance heating applications.

Resistance Wires and Heating Elements

This is the most common use. You will find NiCr wire in nearly every device that uses electricity to create heat, from hair dryers and heat guns to laboratory equipment.

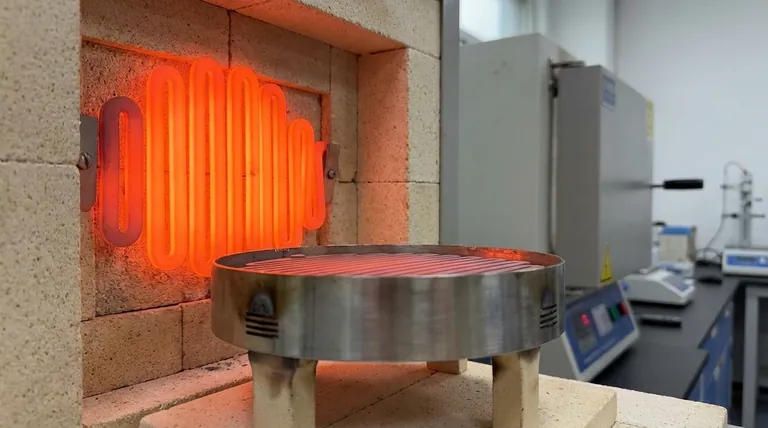

Industrial Furnaces and Ovens

The high-temperature strength and long life of NiCr make it perfect for the demanding environment of industrial heat-treating furnaces, kilns, and large-scale ovens where reliability is paramount.

Consumer Appliances

From the glowing coils in a toaster or electric stovetop to the hidden elements in a water heater or clothes dryer, NiCr is the unseen workhorse of countless household appliances.

Understanding the Trade-offs

While NiCr is an exceptional material, it's important to understand its limitations to use it effectively.

Cost Considerations

While often cited as "inexpensive," this is relative to its high performance. It is more costly than simple iron-based alloys but offers significantly better lifespan and temperature capability. It is a cost-effective choice for its performance class.

Temperature Limitations

Although its melting point is 1400°C, its practical maximum operating temperature is lower, typically around 1100-1200°C. Above this, the protective oxide layer can become less stable, leading to faster degradation.

Mechanical Strength at Temperature

While it maintains good strength at high temperatures, it is not designed for high-stress structural applications at its peak operating heat. Its primary role is as a static heating element.

Making the Right Choice for Your Application

Selecting a heating element material requires matching its properties to your goal. NiCr's balanced profile makes it a versatile default, but understanding these nuances is key.

- If your primary focus is long-term stability and reliability: NiCr's self-healing oxide layer makes it the superior choice for elements that will run for thousands of hours.

- If your primary focus is efficient heat generation in a compact space: NiCr's high resistivity allows for shorter, more powerful element designs compared to more conductive metals.

- If your primary focus is predictable performance across a range of temperatures: The low temperature coefficient of NiCr ensures your power output remains stable and controllable as the element heats up.

Ultimately, Nickel-Chromium's dominance comes from its ability to solve the fundamental challenge of electric heat: how to operate at extreme temperatures without self-destructing.

Summary Table:

| Property | Description |

|---|---|

| Composition | 80% Nickel, 20% Chromium |

| Electrical Resistivity | ~40 μΩ-cm at 20°C |

| Melting Point | ~1400°C |

| Max Operating Temperature | ~1100-1200°C |

| Temperature Coefficient | 0.0004/°C |

| Key Applications | Heating elements, furnaces, consumer appliances |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to enhance efficiency and performance in your heat treatment processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance