The primary factors influencing the aging of Silicon Carbide (SiC) resistors are operating temperature, electrical load density, the surrounding atmosphere, the operational cycle (continuous vs. intermittent), and specific operating techniques. These elements work in concert to gradually increase the resistor's electrical resistance over its service life, a phenomenon often referred to as aging.

The aging of a SiC resistor is not a random degradation but a predictable chemical process. It is overwhelmingly driven by the slow oxidation of the silicon carbide material itself, which forms a less conductive layer of silicon dioxide on its surface.

The Core Mechanism: Surface Oxidation

The fundamental reason SiC resistors age is a slow, high-temperature reaction with oxygen. Understanding this process is key to controlling the component's lifespan.

How Temperature Drives Aging

At elevated temperatures, the silicon carbide (SiC) material reacts with oxygen in the surrounding atmosphere. This chemical reaction forms a thin, glass-like layer of silicon dioxide (SiO₂) on the surface of the resistor.

While this SiO₂ layer is initially protective, it is more electrically resistive than the underlying SiC. As the resistor operates over hundreds or thousands of hours, this layer thickens, causing the component's overall resistance to climb steadily.

The Critical Role of Atmosphere

The composition of the furnace or chamber atmosphere has a direct impact on the rate of oxidation. An oxygen-rich environment will naturally accelerate the aging process.

Conversely, operating in an inert atmosphere, such as one filled with argon or nitrogen, can dramatically slow the oxidation process and significantly extend the resistor's effective life. The presence of water vapor can also increase the rate of aging.

Factors That Accelerate Aging

While oxidation is the core mechanism, other operating conditions can dramatically speed up the process, leading to premature failure.

Electrical Loading as a Temperature Driver

Electrical loading, measured in watts per square inch (or cm²), is a direct measure of the power density on the resistor's surface. It is not an independent factor but rather the primary driver of the resistor's temperature.

A higher watt loading forces the resistor to operate at a higher temperature to dissipate the energy, which in turn accelerates the rate of oxidation and resistance increase. Exceeding the manufacturer's recommended watt loading is the most common cause of rapid aging.

The Stress of Intermittent Operation

Running a system continuously is often less stressful on SiC elements than frequent on/off cycles. This is due to thermal cycling.

As the resistor heats and cools, the SiC material and the SiO₂ oxide layer on its surface expand and contract at different rates. This mismatch in thermal expansion creates mechanical stress, which can lead to micro-cracks in the protective oxide layer. These cracks expose fresh SiC material to oxygen, creating new sites for oxidation and accelerating the overall aging process.

Common Pitfalls and Considerations

Managing SiC components effectively requires balancing performance requirements against the physical limitations of the material.

Contaminants and Fluxing

The protective SiO₂ layer can be compromised by atmospheric contaminants. Certain substances, like alkali metals, can act as a "flux" at high temperatures, chemically attacking the oxide layer and exposing the SiC material to rapid, localized oxidation and failure.

The Myth of "Reconditioning"

Once the resistance of a SiC element has increased due to oxidation, the process is irreversible. The only way to compensate for the increased resistance is to increase the applied voltage to maintain the required power output. This is a core aspect of SiC system design.

Proper Handling and Installation

SiC is a brittle ceramic material. Mechanical shock from improper handling or stress from misaligned mounting can create micro-cracks that become failure points once the resistor is brought to operating temperature.

Making the Right Choice for Your System

Your operational strategy should be directly informed by the physics of SiC aging. Use these principles to guide your design and maintenance procedures.

- If your primary focus is maximizing resistor lifespan: Operate at the lowest effective temperature and watt loading, use continuous rather than intermittent cycles, and ensure a clean, dry operating atmosphere.

- If your primary focus is high process throughput: Select resistors specifically rated for higher temperatures and watt loads, and budget for a shorter service life and more frequent replacements.

- If your system requires frequent thermal cycling: Implement controlled ramp-up and cool-down rates to minimize thermal shock and choose elements designed to withstand the mechanical stress of intermittent use.

By understanding that aging is a predictable process, you can shift from reactive component replacement to proactive system design and lifecycle management.

Summary Table:

| Factor | Effect on Aging | Key Insight |

|---|---|---|

| Operating Temperature | Higher temperatures accelerate oxidation, increasing resistance | Critical for lifespan; keep as low as possible |

| Electrical Load Density | High watt loading raises temperature, speeding up aging | Follow manufacturer specs to avoid premature failure |

| Surrounding Atmosphere | Oxygen-rich or humid environments boost oxidation; inert gases slow it | Use inert atmospheres like argon for longevity |

| Operational Cycle | Frequent on/off cycles cause thermal stress, cracking oxide layers | Prefer continuous operation or controlled cycling |

| Operating Techniques | Contaminants and poor handling can damage resistors, hastening aging | Ensure clean conditions and proper installation |

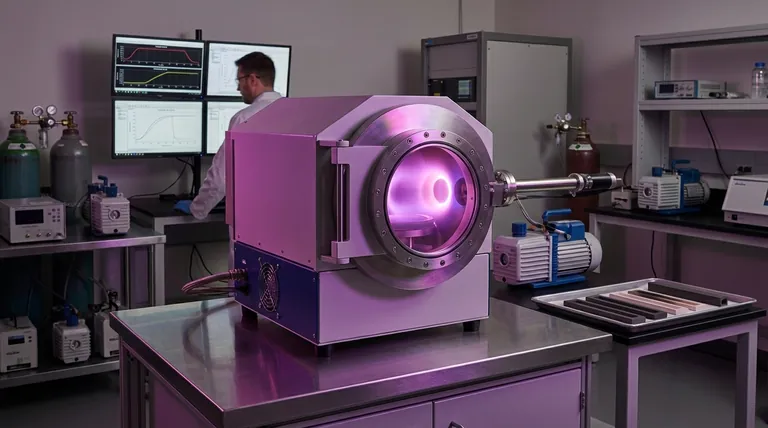

Maximize your lab's efficiency and extend equipment life with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, helping you manage SiC resistor aging effectively. Contact us today to discuss how we can optimize your processes and reduce downtime!

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- How is MPCVD used in manufacturing polycrystalline diamond optical components? Achieve Superior Optical Performance

- What are the key advantages of MPCVD in diamond synthesis? Achieve High-Purity, Scalable Diamond Production

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How does MPCVD compare to other CVD methods like HFCVD and plasma torch? Uncover Superior Film Purity and Uniformity