At its core, a vacuum hot press furnace is distinguished by its unique ability to simultaneously apply high temperature, high mechanical pressure, and a controlled vacuum atmosphere within a single, integrated chamber. While simpler systems may offer one or two of these elements, the vacuum hot press is defined by the precise, synergistic control over all three, enabling the fabrication of highly dense, advanced materials.

The crucial difference is not just the presence of heat or vacuum, but the addition of a powerful mechanical press. This transforms the furnace from a simple heat-treatment device into a sophisticated material synthesis and densification tool.

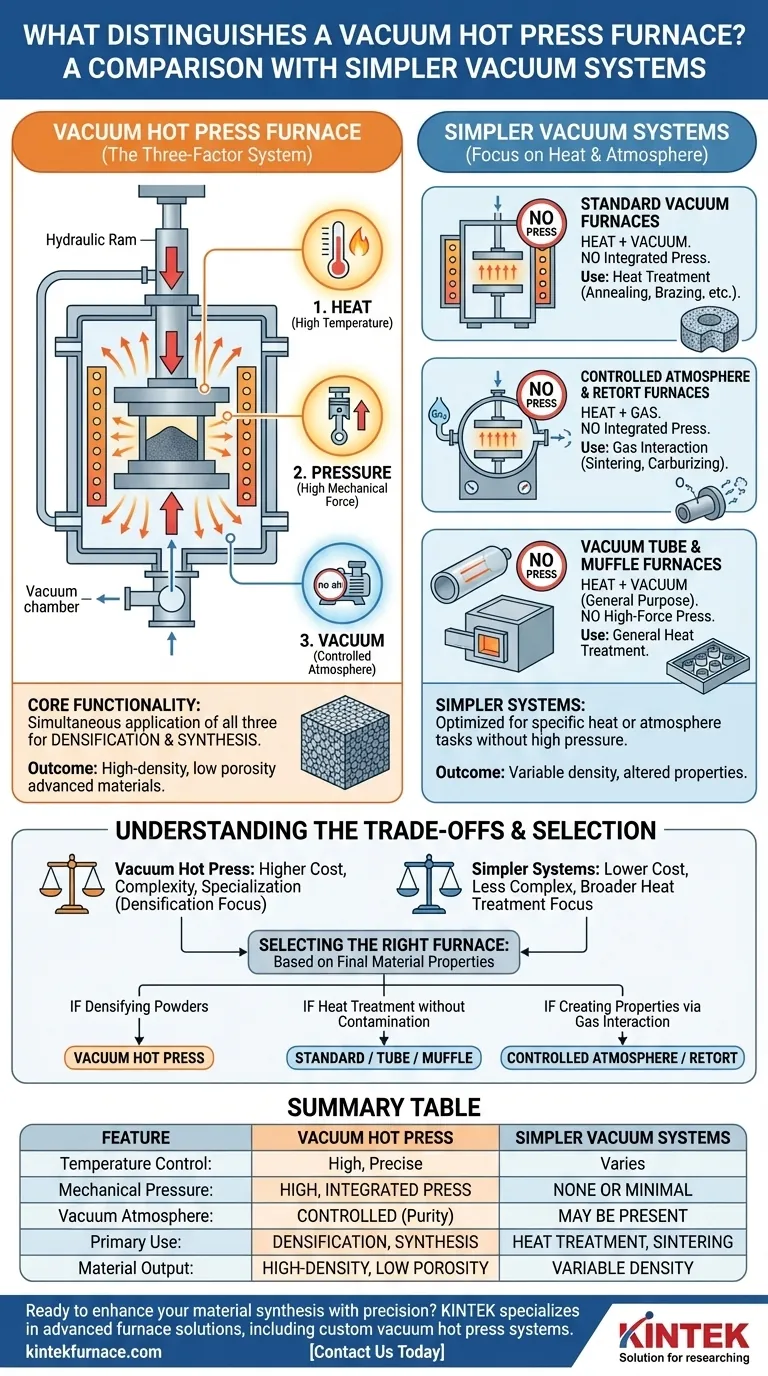

The Core Functionality: A Three-Factor System

A vacuum hot press is an advanced system designed for a very specific purpose: consolidating powders or pre-formed parts into a dense, solid block with minimal porosity. This is achieved by manipulating three variables at once.

H3: Integrating Heat and Pressure

The primary function is to heat a material until it becomes plastic or malleable. At the same time, a hydraulic or mechanical ram applies immense, uniform pressure.

This combination forces the material particles to fuse together, eliminating the voids between them. This process is known as hot pressing or sintering under pressure.

H3: The Role of the Vacuum Atmosphere

The entire process occurs within a vacuum. This is not an afterthought; it is critical for two reasons.

First, it prevents oxidation and other chemical reactions that would otherwise occur at high temperatures, ensuring the purity of the final material. This is essential for reactive metals like titanium or advanced ceramics.

Second, the vacuum helps remove trapped gases from the powder material as it is being compressed, further contributing to a final product with near-theoretical density and superior mechanical properties.

How Simpler Systems Compare

Understanding the limitations of other furnace types clarifies the specific niche of the vacuum hot press. Each is a specialized tool designed for a different set of tasks.

H3: Standard Vacuum Furnaces

A standard vacuum furnace provides heat and a vacuum environment but lacks an integrated mechanical press.

These are workhorses for processes like annealing, brazing, hardening, and degassing. The goal is to alter a material's properties through heat treatment alone, without changing its shape or density through pressure.

H3: Controlled Atmosphere & Retort Furnaces

A retort furnace is designed for high-temperature treatments where the atmospheric chemistry is the key factor.

It may use inert gases (like argon) or reactive gases, but its primary function is not densification under pressure. It's used for processes like sintering or carburizing, where interaction with the surrounding gas is part of the process.

H3: Vacuum Tube & Muffle Furnaces

These systems are primarily used for general-purpose heat treatment in a vacuum. A vacuum tube furnace is ideal for small, uniform samples due to its cylindrical shape.

A vacuum muffle furnace, with its larger, box-like chamber, can accommodate bigger parts or larger batches. Neither system, however, incorporates the high-force pressing capability that defines a hot press.

Understanding the Trade-offs

Choosing a vacuum hot press involves significant trade-offs in complexity, cost, and application focus. It is a highly specialized piece of equipment, not a general-purpose furnace.

H3: Cost and Complexity

The integration of a high-force press system, robust vacuum chamber, and high-temperature heating elements makes vacuum hot press furnaces significantly more complex and expensive to build, operate, and maintain than other furnace types.

H3: Process Specialization

A vacuum hot press excels at one thing: densification. Using it for a simple annealing task would be inefficient and uneconomical. The other furnace types are not "lesser" but are optimized for their specific applications, offering a more cost-effective solution for those tasks.

H3: Material Constraints

The choice is dictated by the material's processing requirements. If a material can be fully sintered to the desired density with heat alone, a hot press is unnecessary. It becomes essential only when pressure is required to achieve the target density or material phase.

Selecting the Right Furnace for Your Process

Your choice must be driven entirely by the final material properties you need to achieve.

- If your primary focus is densifying powders into solid, high-performance parts: You need a vacuum hot press furnace for its unique ability to apply simultaneous heat and pressure.

- If your primary focus is heat treatment without contamination (e.g., annealing, degassing): A standard vacuum furnace or a vacuum muffle/tube furnace is the appropriate and more economical choice.

- If your primary focus is creating specific material properties through interaction with a gas: A controlled atmosphere or retort furnace is designed for exactly this purpose.

Ultimately, matching the furnace's capabilities to your material's fundamental engineering requirements will ensure a successful outcome.

Summary Table:

| Feature | Vacuum Hot Press Furnace | Simpler Vacuum Systems |

|---|---|---|

| Temperature Control | High, precise heating | Varies, often lower |

| Mechanical Pressure | High, integrated press | None or minimal |

| Vacuum Atmosphere | Controlled for purity | May be present |

| Primary Use | Densification, synthesis | Heat treatment, sintering |

| Material Output | High-density, low porosity | Variable density |

Ready to enhance your material synthesis with precision? KINTEK specializes in advanced high-temperature furnace solutions, including custom vacuum hot press systems. Leveraging our exceptional R&D and in-house manufacturing, we provide tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to meet your unique experimental needs. Contact us today to discuss how our deep customization capabilities can drive your research forward!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing