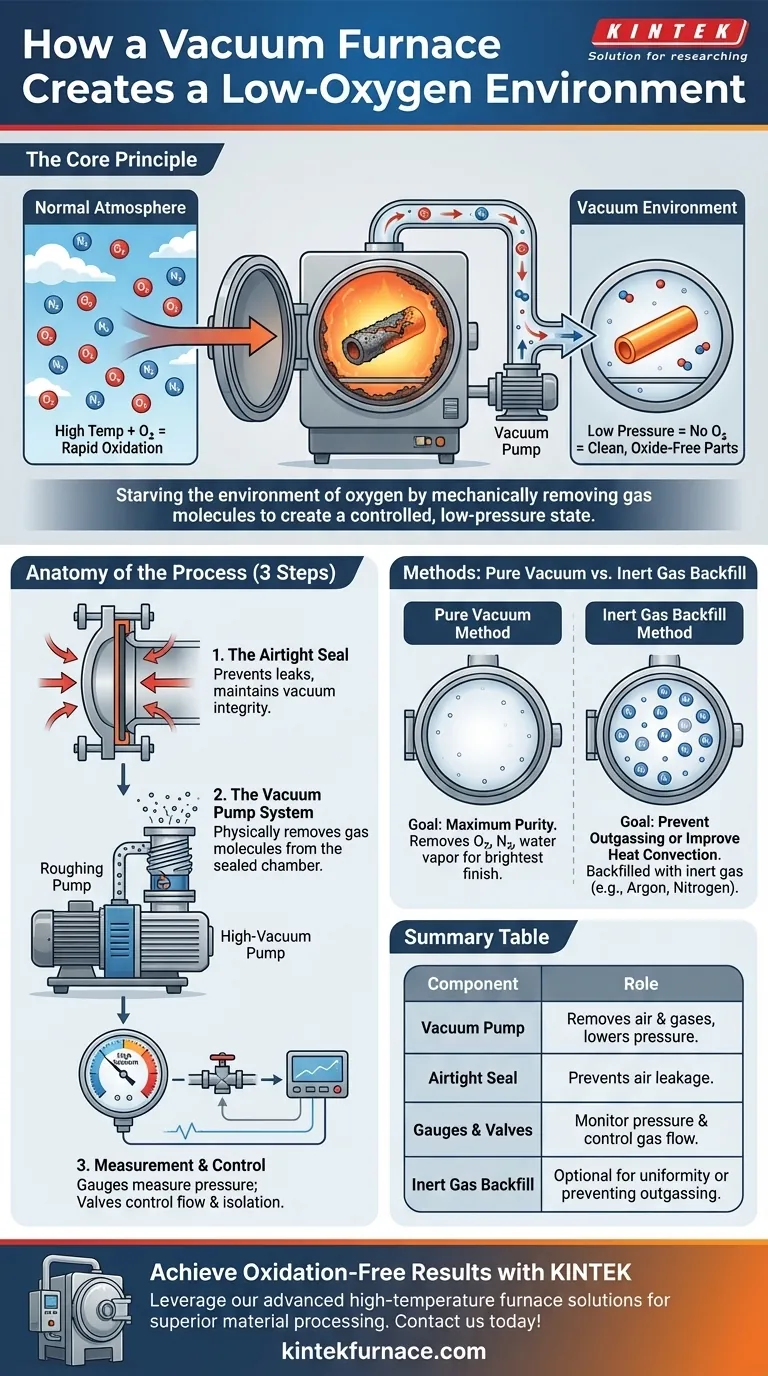

In a vacuum furnace, the low-oxygen environment is created by a vacuum system that mechanically removes air and other gases from a sealed chamber. A powerful vacuum pump acts as the heart of this system, evacuating molecules to achieve a pressure far below the normal atmosphere, thereby starving the environment of the oxygen required for oxidation.

The core principle is not simply "removing oxygen," but creating a controlled, low-pressure environment. By drastically reducing the number of all gas molecules—including oxygen—the system makes it physically impossible for undesirable chemical reactions like oxidation to occur during high-temperature processing.

The Purpose: Why a Low-Oxygen Environment is Critical

Heat is a catalyst for chemical reactions. When processing metals at high temperatures in normal air, the abundant oxygen causes rapid oxidation, which can compromise the material's integrity.

The Problem of Oxidation

Oxidation is a chemical process where a material, like metal, loses electrons when it reacts with oxygen. This reaction forms a brittle oxide layer on the surface.

At the high temperatures used in heat treating, this process accelerates dramatically, weakening the final product, altering its surface finish, and potentially causing it to fail.

How a Vacuum Provides the Solution

A vacuum furnace solves this by removing the primary reactant: oxygen. By pumping the air out of a sealed chamber, the density of oxygen molecules becomes incredibly low.

With virtually no oxygen molecules present to interact with the hot metal surface, oxidation is effectively prevented. This allows for processes like annealing, brazing, and sintering to produce clean, bright, and structurally sound parts.

Anatomy of the Vacuum Creation Process

Creating and maintaining this environment requires more than just a pump. It involves a coordinated system where each component plays a critical role.

Step 1: The Airtight Seal

Before any pumping begins, the furnace chamber must be completely sealed. The most powerful pump in the world cannot achieve a deep vacuum if air is constantly leaking back into the chamber.

This seal is maintained by high-quality flanges, gaskets, and clamps designed to withstand both high temperatures and pressure differentials.

Step 2: The Vacuum Pump System

The vacuum pump is the engine of the system. It physically removes gas molecules from the sealed chamber and expels them into the atmosphere.

Industrial furnaces often use a multi-stage pump system—a "roughing" pump to remove the bulk of the air, followed by a "high-vacuum" pump (like a diffusion or turbomolecular pump) to achieve much lower pressures.

Step 3: Measurement and Control

A vacuum system is incomplete without measurement devices (gauges) and valves.

Gauges precisely measure the pressure inside the chamber, telling the operator the quality of the vacuum. Valves control the flow, isolating the chamber from the pumps or allowing for the controlled introduction of other gases.

Understanding the Trade-offs: Pure Vacuum vs. Inert Gas

While a deep vacuum creates an ideal low-oxygen environment, it's not the only method. Sometimes, a process benefits from a specific, non-reactive atmosphere.

The Pure Vacuum Method

For many applications, achieving the lowest possible pressure (a "deep vacuum") is the goal. This provides the highest level of purity by removing not only oxygen but also nitrogen, water vapor, and other potential contaminants.

The Inert Gas Backfill Method

In this technique, the chamber is first pumped down to a vacuum to remove the air. Then, the chamber is intentionally "backfilled" with a high-purity inert gas, such as argon or nitrogen.

This raises the chamber pressure but keeps the environment free of oxygen. This is often done to provide better heat convection for more uniform heating or to create positive pressure that suppresses the vaporization (outgassing) of certain elements from the metal alloy itself.

How to Apply This to Your Process

Understanding these principles allows you to select the right environment for your specific metallurgical goal.

- If your primary focus is maximum part purity and a bright, oxide-free finish: A deep, pure vacuum is the most effective approach for removing all reactive contaminants.

- If you are heat-treating alloys with volatile elements (like zinc in brass): An inert gas backfill after initial pump-down helps create overpressure to prevent those elements from boiling off.

- If your primary focus is uniform heating in complex parts: An inert gas atmosphere can improve thermal transfer through convection, leading to more consistent results than a pure vacuum.

Mastering the vacuum environment gives you direct control over the final properties and quality of your materials.

Summary Table:

| Component | Role in Creating Low-Oxygen Environment |

|---|---|

| Vacuum Pump | Removes air and gases to achieve low pressure, reducing oxygen molecules. |

| Airtight Seal | Prevents air leakage, maintaining vacuum integrity in the chamber. |

| Gauges and Valves | Monitor pressure and control gas flow for precise environment management. |

| Inert Gas Backfill | Optional step to fill with non-reactive gases like argon for better heat uniformity. |

Ready to achieve oxidation-free results in your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to learn how our vacuum furnaces can enhance your material processing and deliver superior quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today