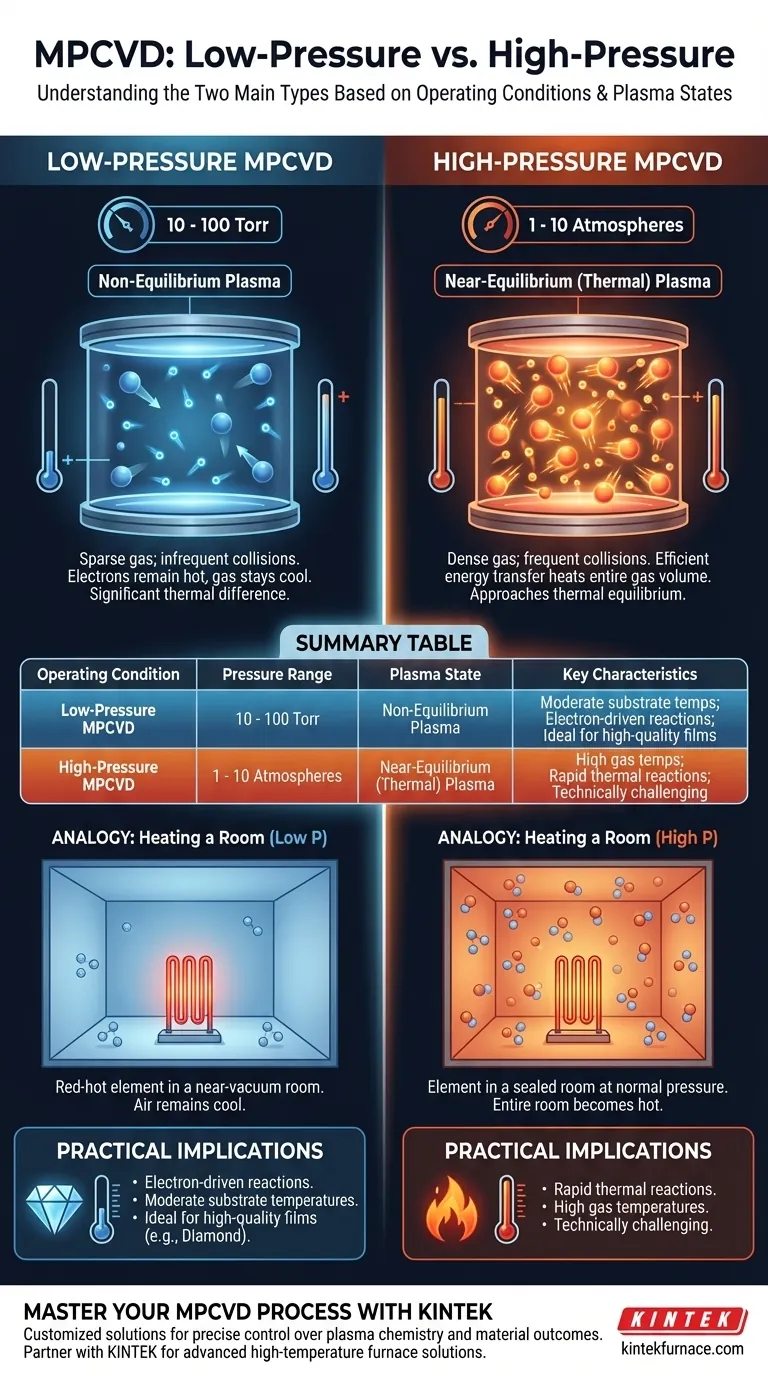

Based on their operating conditions, the two primary types of Microwave Plasma Chemical Vapor Deposition (MPCVD) are low-pressure MPCVD and high-pressure MPCVD. Low-pressure systems typically operate between 10 and 100 Torr, whereas high-pressure systems function in a much denser environment, from 1 to 10 atmospheres. The critical distinction between them lies in how the plasma's energy is distributed.

The choice between low- and high-pressure MPCVD is not merely about the process environment; it is a fundamental decision that dictates the physical state of the plasma. This choice determines whether the plasma is in a state of thermal non-equilibrium or near-equilibrium, which directly controls the chemical reaction pathways and the resulting material properties.

The Physics Behind the Pressure Regimes

To truly understand MPCVD, you must look beyond the pressure values and see how they fundamentally alter the plasma's character. The key concept is thermal equilibrium—or the lack thereof.

Defining the Two States

Low-pressure MPCVD creates what is known as a non-equilibrium plasma. This is the most common form used in many material synthesis applications.

High-pressure MPCVD, by contrast, generates a near-equilibrium plasma, often called a thermal plasma. This state is characterized by intense heat and different chemical dynamics.

The Impact of Particle Collisions

In an MPCVD chamber, microwaves energize free electrons, making them extremely "hot" (high-energy). The operating pressure dictates how this energy is transferred to the surrounding neutral gas atoms and molecules.

At low pressure, the gas is sparse. The high-energy electrons collide infrequently with other particles. As a result, the electrons remain extremely hot, while the heavier, neutral gas particles stay relatively cool. This creates a significant temperature difference, or thermal non-equilibrium.

At high pressure, the gas is dense. The hot electrons collide constantly with the neutral gas particles, efficiently transferring their energy. This heats the entire gas volume, bringing the temperature of the neutral species much closer to that of the electrons. The system approaches thermal equilibrium.

Analogy: Heating a Room

Imagine a single red-hot electric heating element (the electrons) in a large, near-vacuum chamber (low pressure). The element is intensely hot, but the few air molecules in the room remain cool because they rarely touch it. This is a non-equilibrium state.

Now, place that same heating element in a small, sealed room filled with air at normal atmospheric pressure (high pressure). The element quickly heats the air around it through constant collisions, and soon the entire room becomes hot. This is a near-equilibrium state.

Understanding the Practical Implications

The difference between these two plasma states has direct consequences for material deposition. Each approach comes with distinct advantages and challenges.

Why Low-Pressure (Non-Equilibrium) is Widespread

In a non-equilibrium plasma, chemical reactions are driven primarily by the high-energy electrons, not by high gas temperature.

This allows for the deposition of high-quality materials, like diamond films, at substrate temperatures that are significantly lower than the material's melting point. It provides a unique chemical environment that can't be achieved with simple thermal heating.

The Niche for High-Pressure (Near-Equilibrium)

High-pressure MPCVD creates a thermal plasma, which is essentially a controlled, high-temperature gas flame. This is useful for processes that require extremely high temperatures and rapid reaction rates.

However, managing such a hot, dense plasma is technically challenging. It requires more power, and the intense heat can be unsuitable for many temperature-sensitive substrates.

Making the Right Choice for Your Goal

Your application's specific requirements for chemistry and temperature will determine which MPCVD regime is appropriate.

- If your primary focus is activating specific chemical bonds using high-energy electrons while keeping the overall gas and substrate temperature moderate: Low-pressure MPCVD is the correct approach.

- If your primary focus is achieving extremely high gas temperatures to drive rapid thermal reactions: High-pressure MPCVD is the more suitable method.

Ultimately, understanding the relationship between pressure and plasma equilibrium is the key to controlling the deposition process and achieving your desired material outcomes.

Summary Table:

| Operating Condition | Pressure Range | Plasma State | Key Characteristics |

|---|---|---|---|

| Low-Pressure MPCVD | 10 - 100 Torr | Non-Equilibrium Plasma | Moderate substrate temperatures; Electron-driven reactions; Ideal for high-quality films like diamond |

| High-Pressure MPCVD | 1 - 10 Atmospheres | Near-Equilibrium (Thermal) Plasma | High gas temperatures; Rapid thermal reactions; Technically challenging |

Master Your MPCVD Process with KINTEK

Choosing the right MPCVD system—whether low-pressure or high-pressure—is critical to achieving your specific material synthesis goals. The pressure regime dictates the plasma's fundamental state, which directly controls reaction pathways and final material properties.

Why Partner with KINTEK?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced, high-temperature furnace solutions tailored to your unique experimental requirements. Our deep customization expertise is particularly valuable for complex MPCVD applications, where precise control over plasma conditions is paramount.

Our Capabilities for Your MPCVD Success:

- Deep Customization: We design systems to precisely match your required pressure regime and plasma state.

- Advanced Product Line: Our expertise extends across Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD Systems.

- Proven Expertise: We help researchers and engineers in diverse laboratories optimize their processes for superior material outcomes.

Ready to optimize your diamond film deposition or high-temperature synthesis process?

Contact KINTEK today to discuss how our customized MPCVD solutions can help you achieve precise control over plasma chemistry and unlock new material possibilities.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is keeping maintenance records important for MPCVD equipment? Ensure Reliability and Quality in Crystal Growth

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics