At its core, Vacuum Induction Melting (VIM) is about achieving ultimate control over the metallurgical process. By performing melting, refining, and alloying within a tightly controlled vacuum, VIM delivers exceptional material purity, precise chemical composition, and superior mechanical properties that are unattainable with conventional air-melting techniques.

The fundamental advantage of VIM is not just melting metal, but refining it. By removing the reactive atmosphere, the process eliminates the primary source of contamination—air—resulting in cleaner, stronger, and more reliable high-performance alloys.

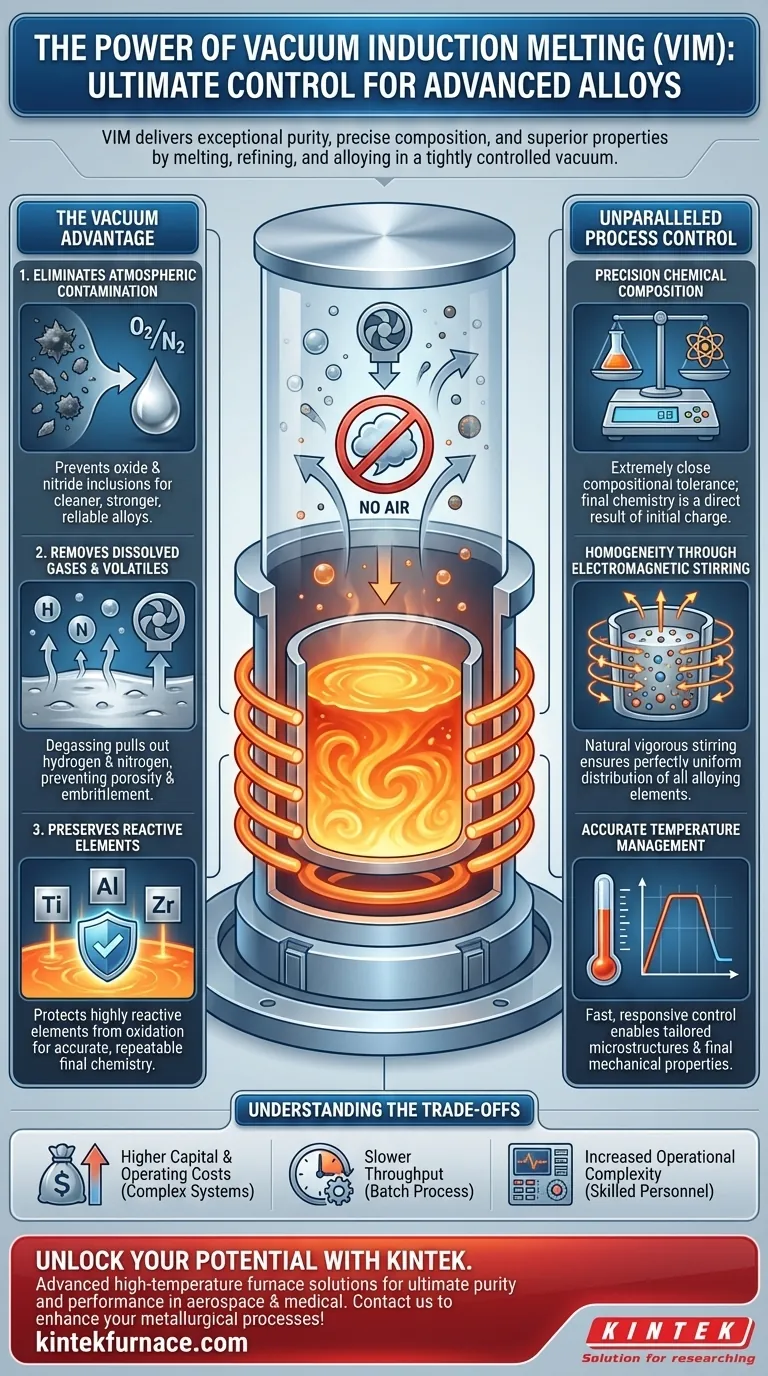

The Foundation of VIM: Why the Vacuum is Everything

The "vacuum" in VIM is the active ingredient that enables its most critical benefits. By removing air and lowering the overall pressure, the entire environment is transformed to favor material purity.

Eliminating Atmospheric Contamination

In conventional melting, molten metal reacts aggressively with oxygen and nitrogen in the air. This reaction forms non-metallic inclusions like oxides and nitrides.

These inclusions act as microscopic stress points within the final material, significantly degrading its fatigue life, ductility, and overall performance. VIM physically removes the atmosphere, preventing these harmful reactions from ever occurring.

Removing Dissolved Gases and Volatiles

The low-pressure environment of a vacuum actively pulls dissolved gases, such as hydrogen and nitrogen, out of the molten metal. This degassing action is crucial for preventing defects like porosity and hydrogen embrittlement.

Furthermore, the vacuum helps remove unwanted, low-vapor-pressure tramp elements, further refining the alloy to an ultra-pure state.

Preserving Reactive Alloying Elements

Many advanced alloys rely on highly reactive elements like titanium, aluminum, and zirconium to achieve their desired properties.

In an air-melt, these expensive elements would be rapidly lost to oxidation. VIM protects them, ensuring they remain in the melt to perform their function. This results in extremely accurate and repeatable final alloy chemistry, batch after batch.

The Power of Unparalleled Process Control

Beyond the vacuum itself, the VIM process offers multiple layers of control that are essential for producing materials with exact specifications.

Precision Over Chemical Composition

VIM allows for the creation of alloys with extremely close compositional tolerance. Because there is no contamination from the atmosphere or from electrodes (as seen in arc melting), the final chemistry is a direct result of the initial charge materials.

This level of precision is non-negotiable for applications in aerospace, medical, and electronics where even minor deviations can lead to failure.

Homogeneity Through Electromagnetic Stirring

The induction heating process creates a natural electromagnetic field that vigorously stirs the molten bath. This inherent stirring action ensures all alloying elements are distributed perfectly evenly.

The result is a completely homogenous melt, free from chemical segregation, which guarantees consistent material properties throughout the final component.

Accurate Temperature Management

Induction heating is incredibly fast, efficient, and responsive. Temperature can be controlled with extreme precision, allowing metallurgists to execute specific thermal profiles.

This control, combined with rapid cooling capabilities, enables the creation of tailored microstructures, which directly dictates the final mechanical properties of the material.

Understanding the Trade-offs

While powerful, VIM is not the universal solution for all melting needs. Its advantages come with specific considerations.

Higher Capital and Operating Costs

VIM furnaces are complex systems that require significant capital investment. The need for robust vacuum chambers, high-capacity pumping systems, and sophisticated controls makes them more expensive to purchase and maintain than standard air-melt furnaces.

Slower Throughput for Bulk Materials

VIM is inherently a batch process. The time required to pump down the chamber, melt, refine, and cast a heat makes its cycle time longer than continuous or semi-continuous melting methods.

For high-volume, low-margin commodity metals, this lower throughput can make VIM less economically viable.

Increased Operational Complexity

Operating a VIM furnace requires highly skilled personnel. Managing the vacuum systems, process controls, and safety protocols is more demanding than running a simple induction or arc furnace in air.

Making the Right Choice for Your Goal

Selecting VIM is a decision driven by the end-use requirements of the material.

- If your primary focus is ultimate material purity and performance: For applications like aerospace turbine blades or medical implants where failure is not an option, VIM is the industry standard.

- If your primary focus is creating complex, reactive superalloys: VIM’s ability to protect sensitive alloying elements and achieve precise chemical targets is its defining strength.

- If your primary focus is high-volume production of standard-grade steel or aluminum: The cost, complexity, and batch nature of VIM are likely prohibitive; other melting technologies are more economical.

Ultimately, choosing VIM is an investment in material integrity, ensuring the final product's properties are defined by design, not by contamination.

Summary Table:

| Advantage | Description |

|---|---|

| Eliminates Atmospheric Contamination | Prevents oxide and nitride formation for cleaner, stronger alloys. |

| Removes Dissolved Gases | Reduces porosity and hydrogen embrittlement through degassing. |

| Preserves Reactive Elements | Protects elements like titanium and aluminum from oxidation loss. |

| Ensures Homogeneity | Uses electromagnetic stirring for uniform alloy distribution. |

| Provides Precise Temperature Control | Enables tailored microstructures and mechanical properties. |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Vacuum & Atmosphere Furnaces, including specialized systems for Vacuum Induction Melting, to deliver superior purity, precise control, and reliable performance for industries like aerospace and medical. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how we can enhance your metallurgical processes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity