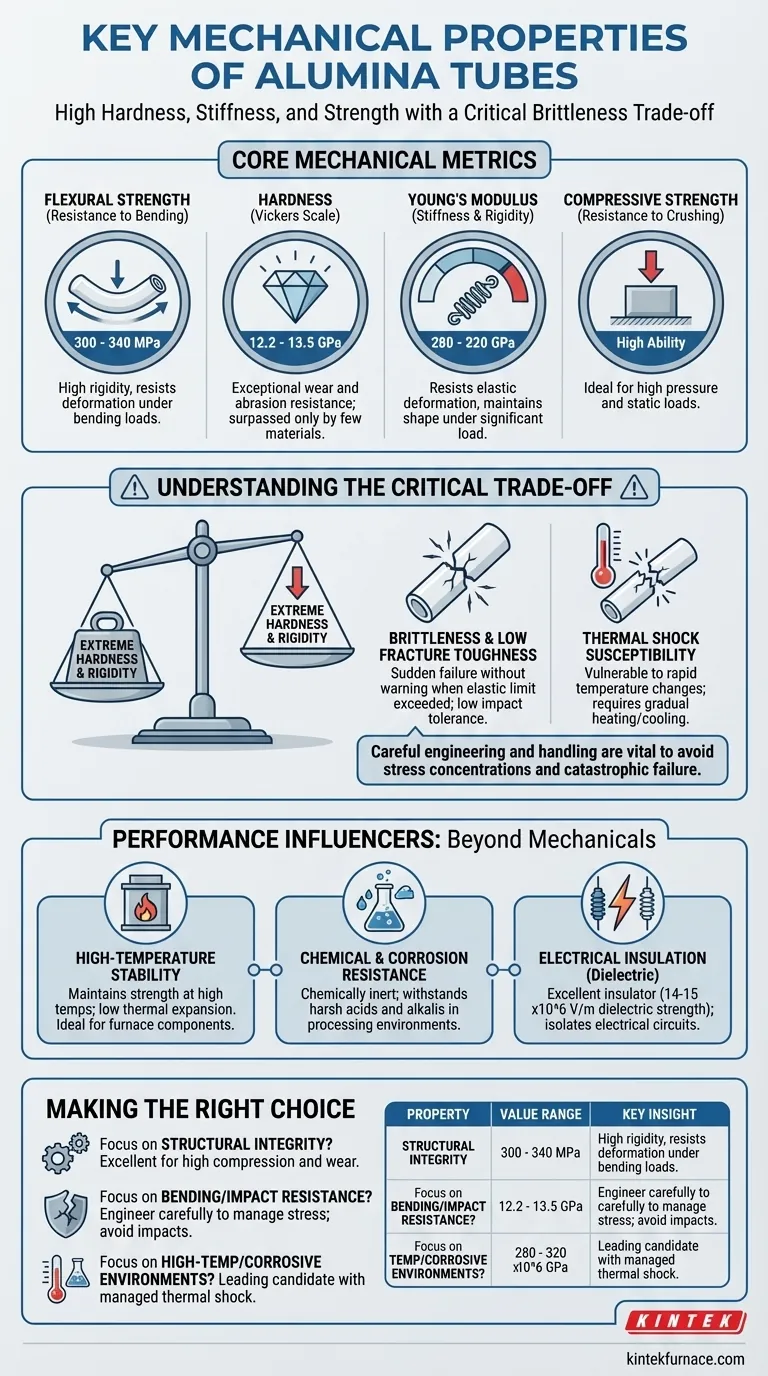

In short, alumina tubes possess a powerful combination of high hardness, stiffness, and strength, particularly under compression. Key metrics include a flexural strength of 300-340 MPa, a hardness of 12.2-13.5 GPa, and a Young's modulus of 280-320 GPa, making them exceptionally resistant to wear, bending, and deformation under load.

Alumina's exceptional mechanical properties make it a top-tier material for high-stress applications. However, its primary strength—extreme hardness and rigidity—is directly linked to its main weakness: brittleness. Understanding this trade-off is the single most important factor for successful implementation.

Deconstructing the Mechanical Properties

To properly evaluate alumina, you must understand what each key property means in a practical context. These values define the material's response to physical force and stress.

Flexural and Compressive Strength (Resistance to Force)

Alumina exhibits a flexural strength (resistance to bending) between 300 and 340 MPa. This gives it a high degree of rigidity in tube form.

It is even more impressive in its compressive strength, or its ability to resist crushing forces. This makes it ideal for applications involving high pressure and static loads.

Hardness (Resistance to Wear and Abrasion)

With a hardness rating of 12.2 to 13.5 GPa on the Vickers scale, alumina is an extremely hard material, surpassed by only a few materials like diamond.

This exceptional hardness translates directly to superior wear and abrasion resistance. It is incredibly difficult to scratch or erode, ensuring a long service life in environments with particulate flow or physical contact.

Young's Modulus (Stiffness and Rigidity)

Alumina has a Young's modulus of elasticity between 280 and 320 GPa. This is a measure of its stiffness.

A high Young's modulus means the material resists elastic deformation under stress. In simple terms, it will not easily bend or flex, maintaining its shape under significant load.

How Other Properties Influence Performance

Mechanical properties do not exist in a vacuum. Alumina's usefulness is amplified by its exceptional thermal and chemical characteristics, which allow it to maintain its mechanical integrity in extreme conditions.

High-Temperature Stability

Alumina maintains its strength and stiffness at very high temperatures. This is coupled with a low coefficient of thermal expansion, meaning it doesn't change size significantly when heated or cooled.

This stability makes it a default choice for furnace components, thermocouple protection, and other high-temperature industrial processes.

Chemical and Corrosion Resistance

Alumina is chemically inert and exhibits outstanding corrosion resistance. It can withstand harsh acids and alkalis that would degrade metals and plastics.

This allows it to be used as a structural component in chemical processing and metallurgical applications where it will be exposed to corrosive substances.

Electrical Insulation

Alumina is an excellent electrical insulator, known as a dielectric material. It has a high dielectric strength (14-15 x10^6 V/m), allowing it to prevent the flow of electricity.

This property is critical when a component must provide structural support while isolating electrical circuits, common in heating elements and semiconductor manufacturing equipment.

Understanding the Trade-offs: The Challenge of Brittleness

No material is perfect. The immense strength and hardness of alumina come with a critical trade-off that must be managed in any design.

High Strength vs. Low Fracture Toughness

The primary drawback of alumina is its brittleness. Unlike metals, which bend or deform plastically before failing, ceramics like alumina fracture suddenly and without warning when their elastic limit is exceeded.

This means it has low tolerance for impacts and requires careful engineering to avoid stress concentrations that could lead to catastrophic failure.

Susceptibility to Thermal Shock

While it performs well at sustained high temperatures, its combination of high stiffness and low thermal expansion makes it vulnerable to thermal shock.

A rapid change in temperature can create internal stresses that exceed the material's strength, causing it to crack. Gradual heating and cooling cycles are essential.

Handling and Installation Demands

Because it is so hard and brittle, alumina requires careful handling. Dropping a tube or improperly tightening a fitting can create microscopic cracks.

These tiny, invisible flaws can become failure points when the component is later subjected to mechanical or thermal stress.

Making the Right Choice for Your Application

Your final decision depends on which properties are most critical for your specific goal.

- If your primary focus is structural integrity under high compression and wear: Alumina is an excellent choice due to its extreme hardness and compressive strength.

- If your primary focus is resistance to bending or impact: You must carefully engineer your design to manage stress and avoid impact, as the material will fracture without warning rather than deforming.

- If your primary focus is performance in a high-temperature, corrosive environment: Alumina's combined thermal stability and chemical inertness make it a leading candidate, provided thermal shock is managed.

By understanding both its exceptional strengths and its inherent limitations, you can confidently leverage alumina for the most demanding applications.

Summary Table:

| Property | Value Range | Key Insight |

|---|---|---|

| Flexural Strength | 300-340 MPa | High resistance to bending and deformation |

| Hardness (Vickers) | 12.2-13.5 GPa | Exceptional wear and abrasion resistance |

| Young's Modulus | 280-320 GPa | High stiffness, minimal elastic deformation |

| Compressive Strength | High (specific values vary) | Ideal for high-pressure and static loads |

| Brittleness | Low fracture toughness | Requires careful handling to avoid sudden failure |

Ready to enhance your lab's performance with custom high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored alumina tube and furnace systems can deliver superior durability, efficiency, and reliability for your high-stress applications!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment