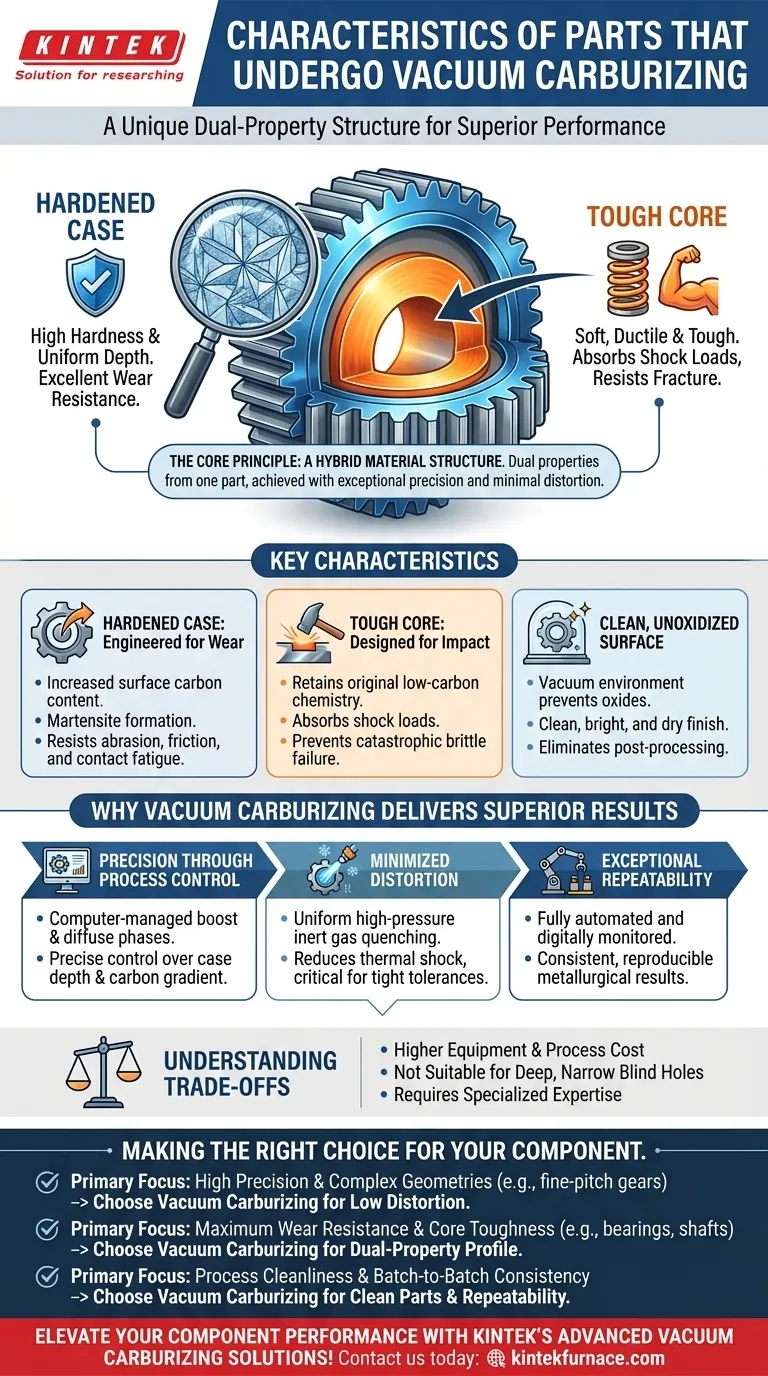

Parts that undergo vacuum carburizing are defined by a unique and highly desirable dual-property structure. They possess an extremely hard, wear-resistant surface layer, known as the case, while the interior of the part, or the core, remains soft, ductile, and tough. This combination allows the component to withstand significant surface wear and contact stress without becoming brittle and prone to fracture under load.

The core benefit of vacuum carburizing is not just hardening a part, but creating a component with two distinct, optimized material profiles: a hard, wear-resistant "skin" and a tough, shock-absorbing "heart." This is achieved with exceptional precision and minimal part distortion, a critical factor for complex, high-performance components.

The Core Principle: A Hybrid Material Structure

Vacuum carburizing, also known as Low-Pressure Carburizing (LPC), is a case-hardening process that fundamentally alters the surface of a steel component. It creates a composite-like structure from a single monolithic part.

The Hardened Case: Engineered for Wear Resistance

The process diffuses carbon atoms into the surface of the steel in a highly controlled vacuum environment. This increases the carbon content only at the surface, which, after quenching, results in a very hard layer of martensite.

This case is characterized by its high hardness and uniform depth, providing excellent resistance to abrasion, friction, and contact fatigue.

The Tough Core: Designed for Impact and Fatigue

The interior of the component is unaffected by the carbon diffusion. It retains its original low-carbon chemistry, resulting in a much softer and more ductile core.

This tough core is critical for the part's overall durability, allowing it to absorb shock loads and resist the propagation of cracks that might initiate at the surface. It prevents catastrophic, brittle failure.

The Clean, Unoxidized Surface

Because the entire process occurs in a vacuum, the parts are never exposed to oxygen at high temperatures. This completely prevents the formation of surface oxides.

The resulting components are clean, bright, and dry, often eliminating the need for post-processing steps like shot blasting or cleaning.

Why Vacuum Carburizing Delivers Superior Results

The characteristics of the final part are a direct result of the precision inherent in the vacuum carburizing process. It offers a level of control that traditional atmospheric carburizing cannot match.

Precision Through Process Control

Modern vacuum furnaces use sophisticated computer controls to manage temperature, vacuum levels, and the introduction of carburizing gas (typically acetylene). The process alternates between "boost" phases (gas introduction) and "diffuse" phases (allowing carbon to soak in).

This cyclic method allows for precise control over the case depth and carbon gradient, ensuring the exact desired properties are achieved consistently.

Minimized Distortion

After carburizing, parts are quenched using high-pressure inert gas (like nitrogen or helium) instead of a harsh liquid like oil. Gas quenching cools the part more uniformly and less severely.

This significantly reduces thermal shock and part distortion, which is a critical advantage for complex, tight-tolerance components like fine-pitch gears.

Exceptional Repeatability

The fully automated and digitally monitored nature of the process ensures that every part in a batch, and every batch over time, receives the exact same treatment.

This leads to highly consistent and reproducible metallurgical results, a vital requirement for safety-critical and high-performance applications.

Understanding the Trade-offs

While powerful, vacuum carburizing is not a universal solution. Understanding its limitations is key to making an informed decision.

Higher Equipment and Process Cost

Vacuum furnaces are more complex and have a higher capital cost than traditional atmospheric furnaces. The process cycle times can also be longer, contributing to a higher per-part cost.

Not Suitable for All Geometries

While excellent for controlling distortion, extremely deep and narrow blind holes can be challenging to carburize uniformly due to limitations in gas flow within such features.

Requires Specialized Expertise

Operating and maintaining a vacuum carburizing system requires a higher level of technical expertise to manage the vacuum systems, gas controls, and computer programming.

Making the Right Choice for Your Component

Ultimately, the decision to use vacuum carburizing depends on the specific performance requirements of your part.

- If your primary focus is high precision and complex geometries: Vacuum carburizing is the superior choice because its low-distortion gas quenching protects tight tolerances.

- If your primary focus is maximum wear resistance combined with core toughness: This process is expertly designed to create the dual-property profile needed for gears, bearings, and shafts.

- If your primary focus is process cleanliness and batch-to-batch consistency: The digitally controlled vacuum environment delivers clean parts and unmatched repeatability for critical applications.

Choosing vacuum carburizing is a strategic decision for producing components where metallurgical precision, performance, and reliability are non-negotiable.

Summary Table:

| Characteristic | Description |

|---|---|

| Hardened Case | High hardness and uniform depth for wear resistance |

| Tough Core | Soft, ductile interior for shock absorption |

| Clean Surface | Bright, oxide-free finish, often eliminating post-processing |

| Minimal Distortion | Achieved through precise gas quenching |

| High Repeatability | Consistent results for safety-critical applications |

Elevate your component performance with KINTEK's advanced vacuum carburizing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Vacuum & Atmosphere Furnaces, designed for precision and minimal distortion. Our strong deep customization capability ensures we meet your unique experimental needs, delivering parts with superior wear resistance and toughness. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing