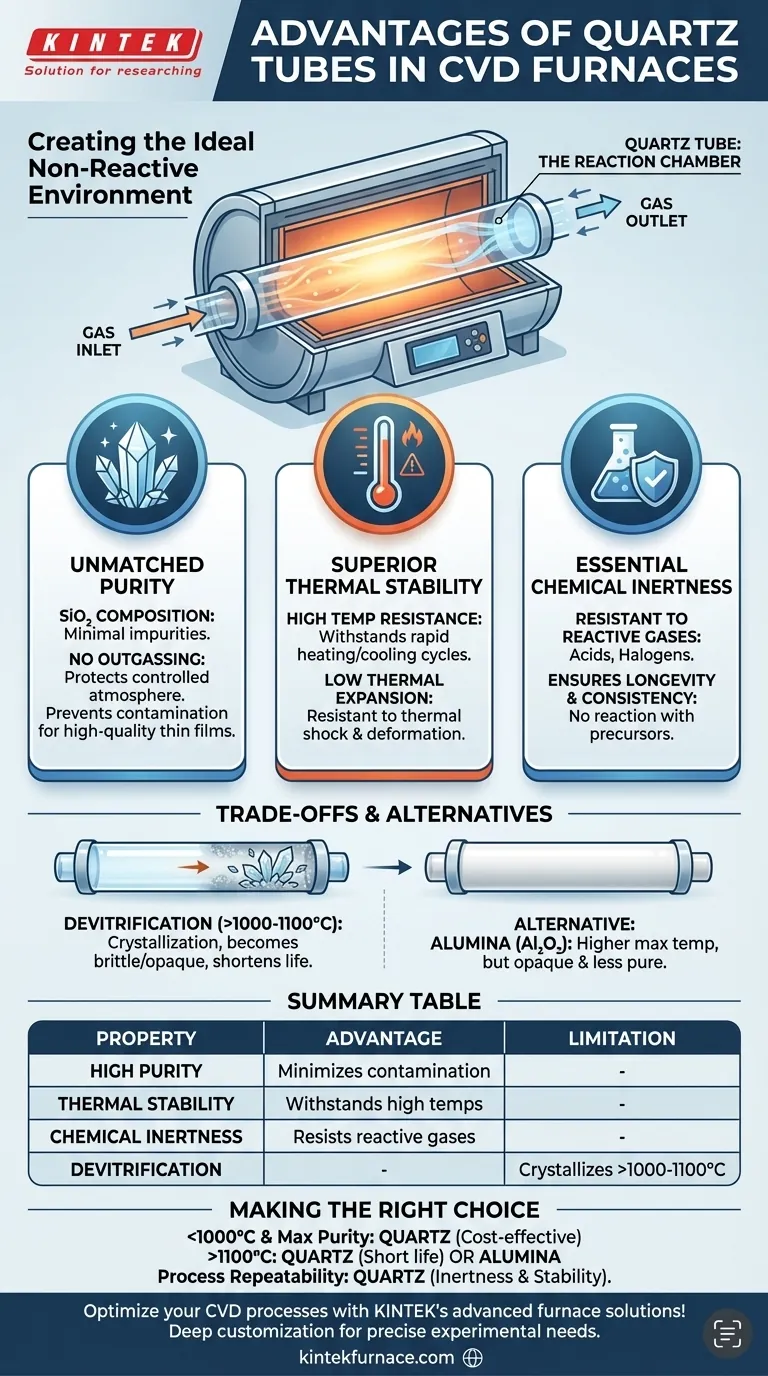

In Chemical Vapor Deposition (CVD), quartz tubes are the industry standard because they uniquely combine high purity, excellent thermal stability, and chemical inertness. This balance of properties is essential for creating the highly controlled, non-reactive environment required for depositing thin films.

The core advantage of quartz is not just its ability to handle heat, but its fundamental role in preventing contamination. It acts as a transparent, clean, and stable chamber, ensuring that the only materials participating in the reaction are the ones you intentionally introduce.

The Critical Role of the Tube Material in CVD

The process tube in a CVD furnace is not merely a piece of hardware; it is the reaction chamber itself. The material chosen for this tube directly dictates the purity of the final product and the repeatability of the process.

Ensuring Unmatched Purity

In CVD, even trace amounts of contaminants can ruin the properties of the deposited thin film. Quartz glass is exceptionally pure, typically composed of silicon dioxide (SiO₂) with minimal impurities.

Unlike metals or many ceramics, quartz does not significantly outgas or release contaminants when heated, protecting the integrity of the controlled atmosphere or vacuum inside.

Superior Thermal Stability

CVD processes operate at extremely high temperatures, often requiring rapid heating and cooling cycles. Quartz exhibits excellent thermal stability, meaning it can withstand these temperatures without deforming.

It also has a very low coefficient of thermal expansion, making it highly resistant to thermal shock and reducing the risk of cracking during temperature changes.

Essential Chemical Inertness

CVD relies on highly reactive precursor gases. The process tube must be inert and not react with these chemicals.

Quartz is resistant to attack from a wide range of acids, halogens, and other reactive substances commonly used in semiconductor and materials science, ensuring the tube's longevity and process consistency.

Understanding the Trade-offs and Limitations

While quartz is the default choice for many applications, it is not without its limitations. Acknowledging these trade-offs is key to successful process design and furnace maintenance.

The Inevitable Process of Devitrification

The most significant limitation of quartz is devitrification. At sustained operating temperatures above 1000-1100°C, the amorphous structure of quartz glass begins to crystallize.

This process causes the tube to become opaque and, more importantly, brittle. Devitrification is an inherent property of quartz and shortens the usable life of the tube, making it a critical maintenance consideration for very high-temperature processes.

Considering Material Alternatives

For processes that must run consistently above the devitrification point of quartz, other ceramic materials are used.

Alumina (Al₂O₃) is a common alternative that offers a higher maximum operating temperature. However, it is opaque and generally less pure than high-quality quartz, making it unsuitable for applications where purity is the absolute priority.

Making the Right Choice for Your Process

Selecting the correct tube material requires balancing your process requirements against the inherent properties and costs of the materials available.

- If your primary focus is maximum purity for general-purpose use below 1000°C: Quartz is the undisputed, most cost-effective choice for your CVD furnace.

- If your primary focus is operating consistently above 1100°C: You must factor in the shortened lifespan due to devitrification or budget for a more robust material like alumina.

- If your primary focus is process repeatability: The chemical inertness and thermal stability of quartz directly contribute to consistent, reproducible results from one run to the next.

Ultimately, understanding these material properties is the first step toward optimizing your CVD process for both performance and longevity.

Summary Table:

| Property | Advantage in CVD |

|---|---|

| High Purity | Minimizes contamination for high-quality thin films |

| Thermal Stability | Withstands high temperatures and rapid cycles without deformation |

| Chemical Inertness | Resists reactive gases, ensuring process consistency and tube longevity |

| Devitrification Limitation | Crystallizes above 1000-1100°C, requiring maintenance or alternative materials |

Optimize your CVD processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Tube and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing purity, stability, and efficiency. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What makes a CVD Tube Furnace essential for material science and nanotechnology? Unlock Precision in Material Synthesis

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More