Fundamentally, the primary advantage of PECVD over thermal Chemical Vapor Deposition (CVD) is its ability to deposit high-quality films at significantly lower temperatures. By using an energy-rich plasma rather than high heat to drive chemical reactions, PECVD opens the door to processing temperature-sensitive materials and offers a greater degree of control over the final properties of the deposited film.

Choosing a deposition method often hinges on balancing film quality with substrate limitations. PECVD overcomes the high-temperature barrier of thermal CVD, enabling faster, more versatile, and often more cost-effective film deposition on a wider range of materials.

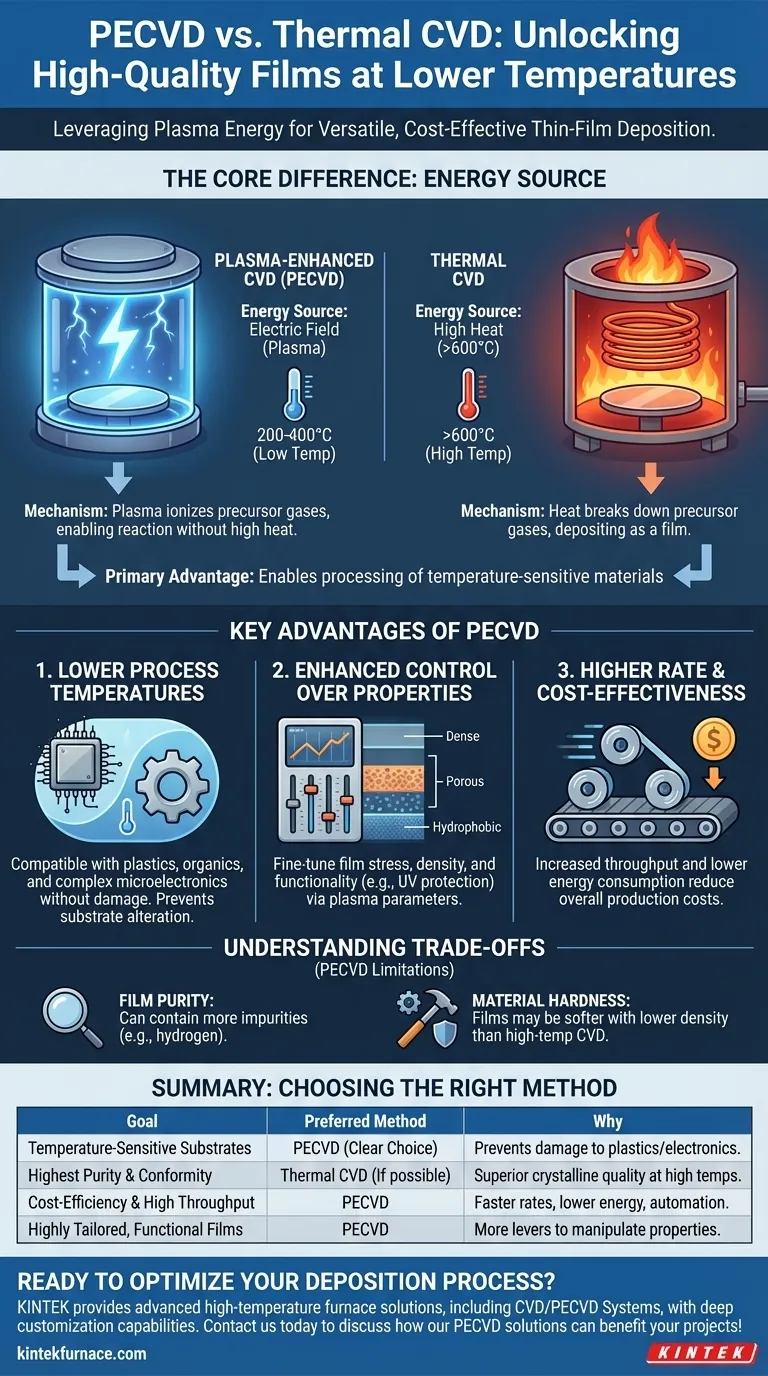

The Core Difference: Plasma vs. Thermal Energy

To understand the advantages, we must first look at the fundamental mechanism of each process. The choice between them is a choice between two different energy sources.

How Thermal CVD Works

Traditional thermal CVD relies exclusively on high heat (often >600°C) to provide the energy needed to break down precursor gases. These decomposed molecules then react and deposit as a solid thin film on the heated substrate.

This high-temperature requirement is the process's primary limitation, as it can damage or alter the properties of the substrate or underlying device layers.

How PECVD Works

Plasma-Enhanced CVD (PECVD) uses an electric field to ionize the precursor gases, creating a state of matter known as plasma. This plasma is a highly energetic environment that effectively breaks down the gas molecules.

Because the energy for the reaction comes from the plasma rather than thermal agitation, the substrate can be kept at a much lower temperature (typically 200-400°C).

Key Advantages of the PECVD Process

The shift from thermal energy to plasma energy creates several distinct operational advantages that make PECVD a preferred method for many modern applications.

Lower Process Temperatures

This is the most significant advantage. The ability to deposit films at lower temperatures makes PECVD compatible with substrates that would be destroyed by thermal CVD.

This includes plastics, organic materials, and complex microelectronic devices where high heat would damage previously fabricated components or alter their precise electrical characteristics.

Enhanced Control Over Film Properties

The plasma process provides additional variables that can be controlled to fine-tune the final film. By adjusting factors like plasma power, frequency, and gas composition, technicians can manipulate the film's properties.

This allows for a high degree of tailorability, enabling the creation of films with low stress, specific densities, or functional characteristics like hydrophobicity and UV protection.

Improved Deposition Rate and Cost-Effectiveness

Even at lower temperatures, PECVD often achieves higher deposition rates than thermal CVD. This increases manufacturing throughput.

Combined with lower energy consumption from reduced heating and a high potential for automation, PECVD can significantly reduce overall production costs, making it economically attractive for large-scale production.

Understanding the Trade-offs and Limitations

No technology is a universal solution. An objective evaluation of PECVD requires acknowledging its limitations compared to other deposition methods.

Film Quality and Purity

While excellent for many applications, the films from PECVD can sometimes contain more impurities, such as hydrogen, compared to the high-purity crystalline films produced by high-temperature thermal CVD processes like LPCVD.

Material Hardness and Durability

PECVD films can be softer and have lower density than their high-temperature counterparts. This may result in limited wear resistance, making them unsuitable for applications requiring extreme mechanical durability.

Process and Material Considerations

The creation of plasma introduces complexity. Furthermore, some precursor gases used in PECVD, particularly halogenated compounds, can pose health and environmental concerns that require careful management.

Making the Right Choice for Your Application

Your choice between PECVD and thermal CVD depends entirely on your project's specific constraints and desired outcomes.

- If your primary focus is processing temperature-sensitive substrates: PECVD is the clear choice, as its low-temperature operation prevents damage to materials like plastics or already-fabricated microelectronics.

- If your primary focus is achieving the highest possible film purity and conformity: Thermal CVD might be preferred for specific applications where its high-temperature process yields superior crystalline quality, assuming the substrate can tolerate the heat.

- If your primary focus is cost-efficiency and high throughput: PECVD often holds the advantage due to its faster deposition rates, lower energy use, and high level of automation.

- If your primary focus is creating highly tailored or functional films: PECVD provides more levers to manipulate film properties like stress, density, and surface characteristics than thermal processes.

By understanding these core differences, you can confidently select the deposition technology that aligns with your technical requirements and strategic goals.

Summary Table:

| Advantage | Description |

|---|---|

| Lower Process Temperatures | Enables deposition on temperature-sensitive materials like plastics and microelectronics without damage. |

| Enhanced Control Over Film Properties | Allows fine-tuning of stress, density, and functional traits via plasma parameters. |

| Improved Deposition Rate and Cost-Effectiveness | Higher throughput and lower energy use reduce production costs for large-scale applications. |

Ready to optimize your thin-film deposition process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements for superior film quality and efficiency. Contact us today to discuss how our PECVD solutions can benefit your projects!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the main advantages of PECVD tube furnaces compared to CVD tube furnaces? Lower Temp, Faster Deposition, and More

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- What are the future trends in CVD technology? AI, Sustainability, and Advanced Materials

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs