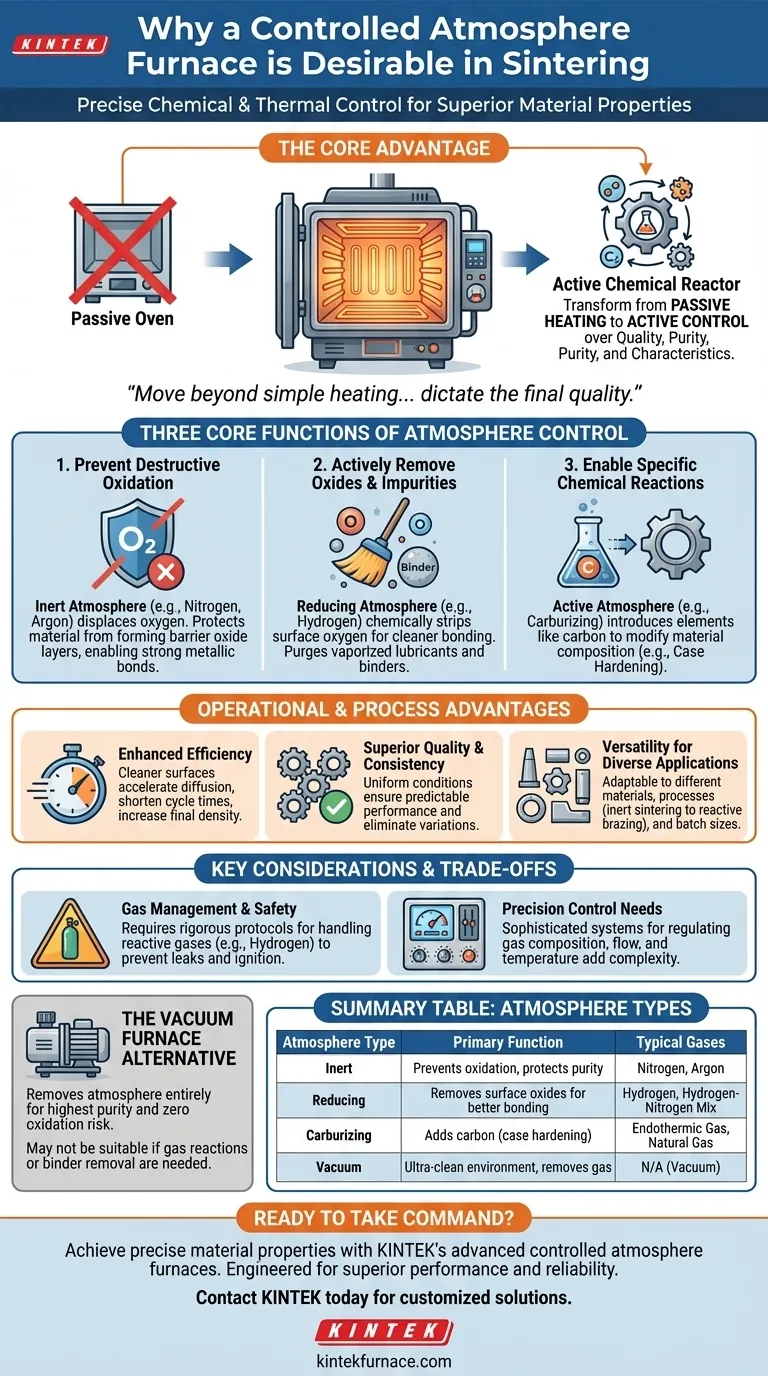

In short, a controlled atmosphere furnace is desirable for sintering because it provides precise chemical and thermal control over the workpiece at high temperatures. This prevents destructive reactions like oxidation, actively removes contaminants and existing oxides, and ensures the final product achieves its intended structural integrity and material properties.

The fundamental reason to use a controlled atmosphere is to move beyond simple heating. It allows you to transform the furnace from a passive oven into an active chemical reactor, giving you the power to dictate the final quality, purity, and characteristics of the sintered part.

The Core Functions of Atmosphere Control

Sintering involves bonding material powders together just below their melting point. At these high temperatures, materials are highly reactive. Leaving them exposed to ambient air would be catastrophic for most applications. A controlled atmosphere mitigates these risks and introduces new processing capabilities.

Preventing Destructive Oxidation

At sintering temperatures, most metals will readily react with oxygen in the air. This forms a layer of oxide on the powder particles, which acts as a barrier, preventing the strong, direct metallic bonds needed for densification and strength. An inert atmosphere, typically nitrogen or argon, displaces the oxygen and protects the material.

Actively Removing Oxides and Impurities

A controlled atmosphere can do more than just protect; it can actively clean the material.

- Reducing Atmospheres: Using a gas like hydrogen creates a reducing atmosphere. This environment chemically strips oxygen atoms from any pre-existing oxides on the powder surfaces, resulting in a cleaner, more active surface for superior sintering.

- Purging Binders: The controlled flow of gas is also critical for removing lubricants and binders used in the initial powder pressing stage. The atmosphere acts as a carrier, sweeping these vaporized contaminants out of the furnace chamber before they can interfere with the final product.

Enabling Specific Chemical Reactions

The atmosphere can be an active ingredient in the final material's composition. The most common example is a carburizing atmosphere, which is rich in carbon. This allows you to intentionally diffuse carbon into the surface of steel parts during the sintering cycle, a process known as case hardening.

Operational and Process Advantages

This level of control directly translates into significant improvements in production efficiency, product quality, and process versatility.

Enhanced Sintering Efficiency

By promoting cleaner particle surfaces and providing the ideal chemical environment, a controlled atmosphere can accelerate the diffusion and bonding processes at the heart of sintering. This can lead to more effective shrinkage, higher final density, and shorter overall cycle times.

Superior Product Quality and Consistency

The combination of uniform heating and precise atmospheric regulation ensures that every part in a batch, and every batch over time, has highly consistent material properties. This eliminates variations caused by uncontrolled atmospheric reactions, leading to cleaner, higher-quality products with predictable performance.

Versatility for Diverse Applications

Controlled atmosphere furnaces are engineered for flexibility. They often feature larger chamber volumes suitable for batch processing and can handle a wide range of part sizes and shapes. Their ability to manage various gas compositions makes them adaptable to different materials and processes, from basic inert sintering to complex reactive brazing.

Understanding the Trade-offs and Considerations

While powerful, these furnaces are not without their operational demands. Achieving their benefits requires a clear understanding of the associated complexities.

Gas Management and Safety

The gases used—especially reactive ones like hydrogen—require careful handling, storage, and management. Implementing rigorous safety protocols to prevent leaks, accidental mixing, and ignition hazards is non-negotiable.

The Need for Precision Control

The system's effectiveness hinges on its ability to precisely regulate gas composition, flow rates, and temperature profiles. This necessitates sophisticated control systems and sensors, adding to the furnace's initial cost and operational complexity.

The Vacuum Furnace Alternative

For applications demanding the absolute highest purity and zero risk of atmospheric reaction, a vacuum furnace is a key alternative. Instead of replacing the atmosphere, it removes it entirely. This provides an exceptionally clean environment but may not be suitable for processes that require a specific gas to remove binders or participate in a reaction.

Making the Right Choice for Your Sintering Goal

Your specific material and desired outcome will determine the best atmospheric approach.

- If your primary focus is preventing any oxidation and achieving high purity: An inert atmosphere (nitrogen, argon) or a vacuum furnace is essential.

- If you need to remove existing surface oxides for superior bonding: A reducing atmosphere containing hydrogen is the optimal choice.

- If you are producing large batches and require consistent, high-quality results: The precise control and scalability of a controlled atmosphere furnace justify the investment.

- If your process involves adding an element like carbon to the material: An active, controlled atmosphere (e.g., carburizing) is the only method to achieve this.

Ultimately, controlling the furnace atmosphere gives you direct command over the metallurgical outcome of your process.

Summary Table:

| Atmosphere Type | Primary Function | Typical Gases Used |

|---|---|---|

| Inert | Prevents oxidation and protects material purity | Nitrogen, Argon |

| Reducing | Removes existing surface oxides for better bonding | Hydrogen, Hydrogen-Nitrogen Mix |

| Carburizing | Adds carbon to the material surface (case hardening) | Endothermic Gas, Natural Gas |

| Vacuum | Provides an ultra-clean environment by removing all gas | N/A (Vacuum) |

Ready to Take Command of Your Sintering Process?

Achieving the precise material properties and structural integrity you require demands more than just heat—it demands complete control over the chemical environment.

KINTEK's advanced controlled atmosphere furnaces are engineered to provide that exact level of precision. Leveraging our exceptional in-house R&D and manufacturing capabilities, we deliver robust solutions tailored to your unique challenges. Whether your goal is preventing oxidation, actively reducing surface oxides, or enabling complex reactions like carburizing, our furnaces—including our Tube, Box, and Vacuum & Atmosphere models—are built for superior performance and reliability.

Let us help you transform your sintering outcomes. Our team is ready to discuss your application and develop a customized solution that ensures consistency, purity, and efficiency in every batch.

Contact KINTEL today to speak with an expert and discover the right furnace for your laboratory's needs.

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab