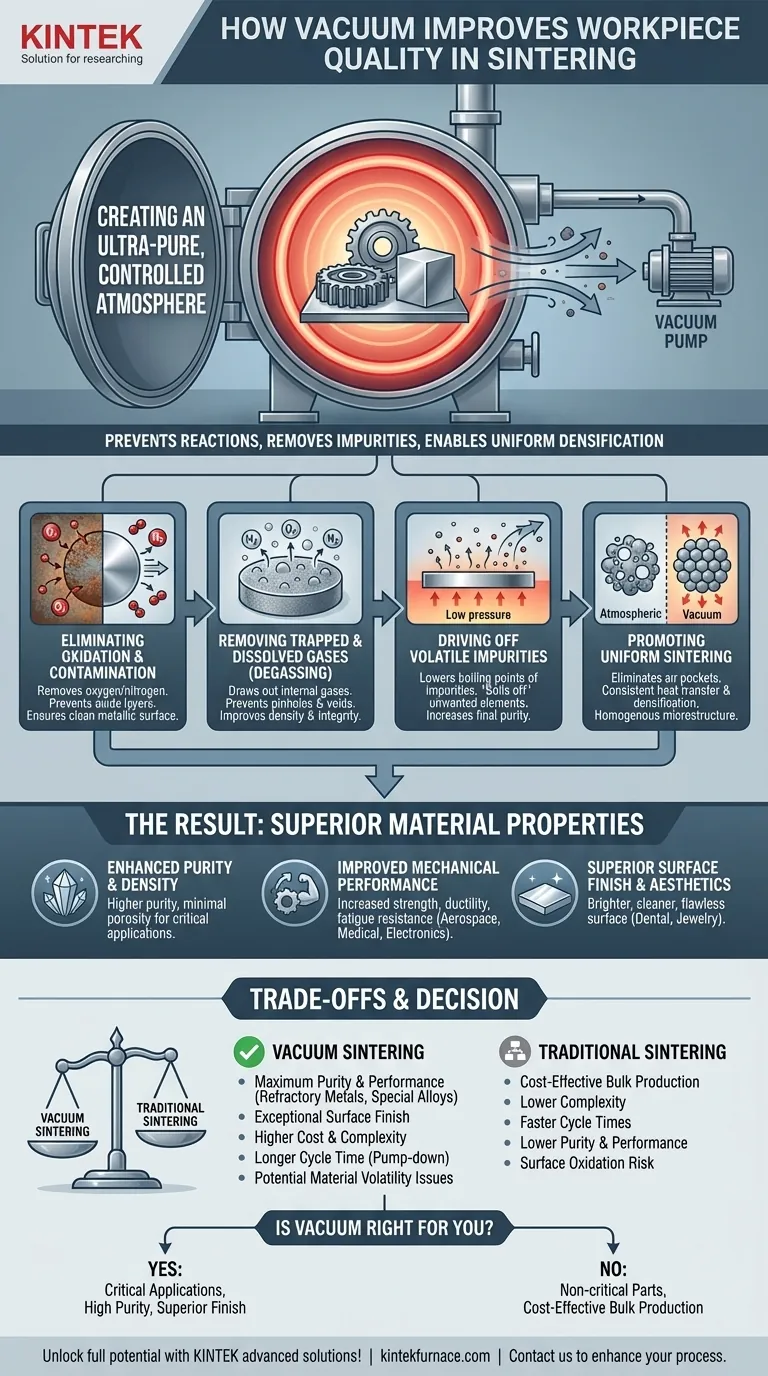

At its core, a vacuum environment improves workpiece quality during sintering by creating an ultra-pure, controlled atmosphere. This prevents unwanted chemical reactions, removes embedded impurities, and allows the material to densify uniformly, resulting in a final product with superior purity, strength, and surface finish.

By removing the reactive and disruptive elements of air, vacuum sintering shifts the focus from merely heating a material to fundamentally refining it. This process unlocks the full potential of the material's intrinsic properties.

The Core Mechanisms: How Vacuum Purifies and Protects

To understand the benefits, we must look at the specific physical and chemical processes that a vacuum enables. It is not simply the absence of air, but the active removal of contaminants at multiple levels.

Eliminating Oxidation and Contamination

The most immediate benefit of a vacuum is the removal of atmospheric gases, primarily oxygen and nitrogen.

When heated, many materials readily react with oxygen, forming brittle and undesirable oxide layers on their surface. A vacuum furnace removes these reactive gases, completely preventing oxidation and ensuring the material's surface remains clean and metallic.

Removing Trapped and Dissolved Gases

Many raw metal powders contain gases like hydrogen, oxygen, and nitrogen that are dissolved within the material itself.

During heating in a vacuum, these trapped gases are drawn out of the workpiece—a process known as degassing. This is critical for preventing the formation of microscopic voids or pinholes, which compromise the material's density and structural integrity.

Driving Off Volatile Impurities

The low-pressure environment of a vacuum effectively lowers the boiling point of many substances.

This principle is used to remove volatile impurities that may be present in the raw material. As the workpiece heats up, these unwanted elements essentially "boil off" and are evacuated by the vacuum pump, resulting in a significantly purer final product.

Promoting Uniform Sintering

In an atmospheric furnace, trapped pockets of air can impede the uniform bonding of material particles.

A vacuum eliminates this issue, allowing for more consistent heat transfer and part densification. This leads to a more homogenous microstructure and a more uniform distribution of alloy elements, which is vital for the performance of special alloys.

The Result: Superior Material Properties

The purification and protection offered by the vacuum environment translate directly into measurable improvements in the final workpiece.

Enhanced Purity and Density

By removing oxides, dissolved gases, and volatile contaminants, the final product achieves a much higher level of purity and density. This is essential for high-performance applications where even trace amounts of impurities can lead to failure.

Improved Mechanical Performance

A denser, purer material with minimal porosity exhibits superior mechanical properties. This includes increased strength, ductility, and fatigue resistance, making vacuum-sintered parts ideal for demanding roles in aerospace, medical, and electronics industries.

Superior Surface Finish and Aesthetics

The prevention of surface oxidation results in a brighter, cleaner, and more consistent finish. This is not only a sign of high quality but is a critical requirement for products like dental ceramics, medical implants, and precious metal jewelry.

Understanding the Trade-offs

While highly effective, vacuum sintering is not a universal solution. It involves specific considerations and trade-offs compared to traditional atmospheric furnaces.

Cost and Complexity

Vacuum furnaces are inherently more complex and expensive to purchase, operate, and maintain than their atmospheric counterparts. The need for robust vacuum pumps, seals, and control systems adds to the overall cost.

Cycle Time

Achieving a deep vacuum and ensuring a leak-free environment takes time. This "pump-down" phase can extend the total cycle time of the sintering process.

Material Volatility

The same mechanism that removes volatile impurities can also work against you. If your alloy contains essential elements with a high vapor pressure (a tendency to evaporate), the vacuum can unintentionally draw them out, altering the final composition of the material. This requires careful control over temperature and vacuum levels.

Is Vacuum Sintering Right for Your Application?

Choosing the right sintering process depends entirely on the required properties of your final product.

- If your primary focus is maximum purity and performance: Vacuum sintering is the superior choice for refractory metals (tungsten, molybdenum), special alloys, and components for critical applications like aerospace or medical implants.

- If your primary focus is exceptional surface finish: The process is ideal for parts where aesthetics and a flawless surface are paramount, such as in dental ceramics or high-end jewelry.

- If your primary focus is cost-effective bulk production of non-critical parts: A traditional atmospheric furnace may be more economical if the high purity and enhanced mechanical properties provided by a vacuum are not strictly necessary.

By mastering the environment in which a material is formed, you ultimately master the quality of the final product.

Summary Table:

| Mechanism | Benefit |

|---|---|

| Eliminates Oxidation | Prevents surface reactions, ensuring clean, metallic surfaces |

| Removes Trapped Gases | Reduces pinholes and voids, improving density and integrity |

| Drives Off Volatile Impurities | Boosts material purity by removing contaminants |

| Promotes Uniform Sintering | Ensures consistent densification and microstructure |

| Resulting Properties | Enhanced strength, ductility, fatigue resistance, and surface finish |

Unlock the full potential of your materials with KINTEK's advanced vacuum sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior purity, strength, and finish for critical applications in aerospace, medical, and electronics. Don't settle for less—contact us today to discuss how we can enhance your sintering process and achieve outstanding results!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering