For the electronics industry, vacuum brazing is a mission-critical process, not merely a joining technique. It is the definitive method for manufacturing high-performance thermal management components like heat sinks, cold plates, and hermetically sealed enclosures. The process creates exceptionally clean, strong, and thermally conductive joints, which are essential for the reliability and longevity of modern electronic systems that generate immense heat.

The core problem in advanced electronics is managing heat without compromising mechanical integrity. Vacuum brazing directly solves this by creating a single, thermally efficient assembly with minimal internal stress, ensuring heat is removed reliably while preserving the component's precise form and strength.

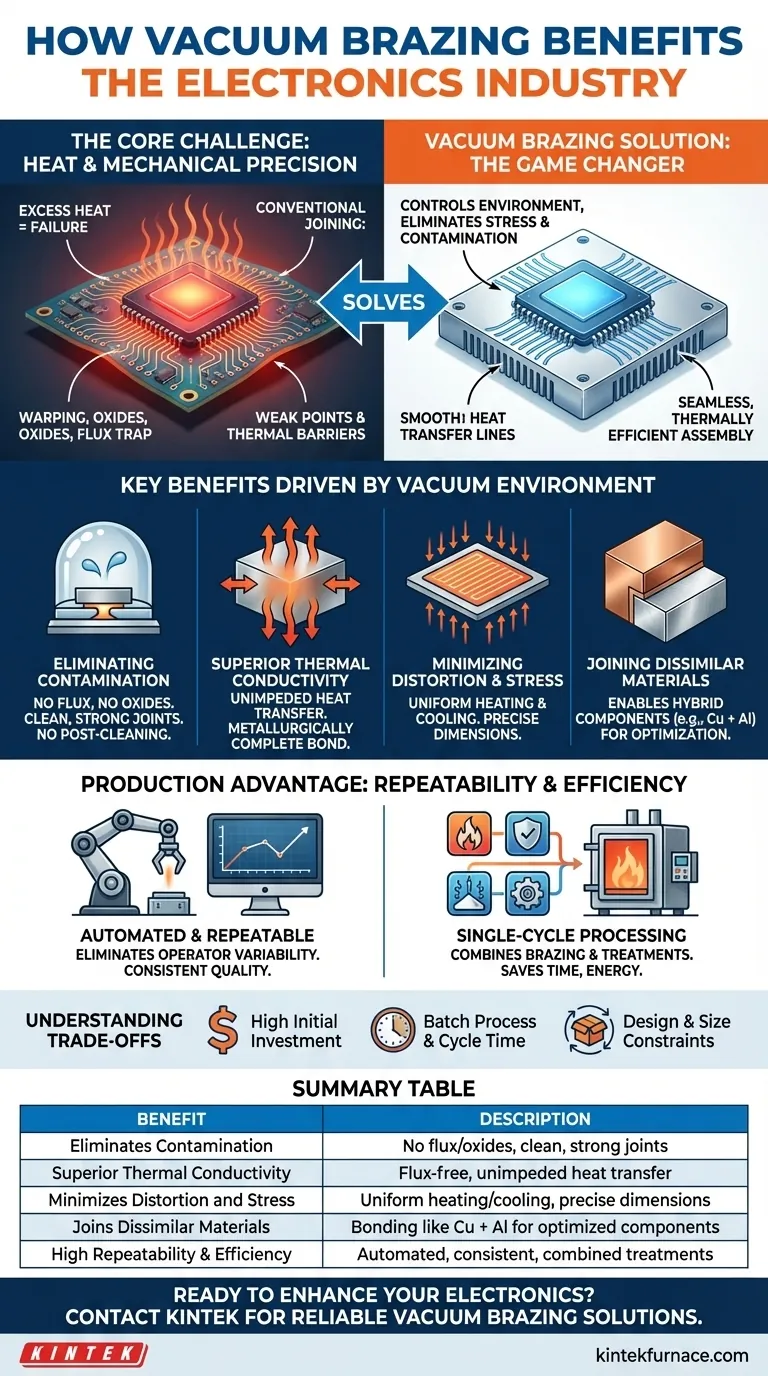

The Core Challenge: Heat and Mechanical Precision

In modern electronics, performance is directly limited by the ability to dissipate heat. As components become smaller and more powerful, the thermal challenges intensify.

Why Thermal Management is Critical

Excess heat is the primary cause of electronic component failure. It degrades performance, reduces processing speed, and drastically shortens the lifespan of sensitive microelectronics. Effective thermal management is not an option; it is a fundamental requirement.

The Problem with Conventional Joining

Traditional methods like welding or torch brazing in open air introduce significant problems. The high, localized heat causes warping and distortion, while exposure to oxygen creates oxides on the joint surfaces. These oxides and the flux used to remove them can become trapped, creating weak points and, more importantly, acting as thermal barriers that prevent efficient heat transfer.

How Vacuum Brazing Solves the Core Challenge

Vacuum brazing addresses these fundamental issues by controlling the entire environment. By performing the process in a vacuum, the root causes of contamination and stress are eliminated.

Eliminating Contamination with a Vacuum

Removing air from the furnace prevents the formation of oxides. This allows the brazing filler metal to flow cleanly and bond directly with the parent materials. As a result, no flux is required, which completely eliminates the risk of flux entrapment and the need for corrosive post-braze cleaning. The result is a bright, clean, and structurally sound joint.

Achieving Superior Thermal Conductivity

The primary benefit of a flux-free, oxide-free joint is unimpeded thermal transfer. The bond created during vacuum brazing is metallurgically complete and free of voids or inclusions. This creates a seamless pathway for heat to move from a hot component (like a CPU) into a thermal management assembly (like a cold plate or heat sink).

Minimizing Distortion and Residual Stress

Vacuum furnaces heat entire assemblies slowly and uniformly. This prevents the thermal shock and localized stress that cause parts to warp. A controlled cool-down cycle further reduces residual stress, ensuring the final product maintains its precise dimensions and structural integrity. This is critical for components that must mate perfectly with other parts of an electronic system.

Joining Dissimilar Materials

Many high-performance thermal solutions require joining different materials, such as copper (for excellent conductivity) to aluminum (for light weight). Vacuum brazing excels at this, enabling the creation of optimized hybrid components that would be difficult or impossible to produce with other methods.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. Understanding its operational realities is key to using it effectively.

High Initial Investment

Vacuum furnaces represent a significant capital expenditure. The cost of the equipment and its installation means this process is typically employed by specialized manufacturers focused on high-value or high-volume production.

Batch Processing and Cycle Time

Vacuum brazing is a batch process, not a continuous one. A full cycle of pumping down the vacuum, heating, brazing, and cooling can take several hours. While a single furnace can process many parts at once, it is not suited for on-demand, single-piece fabrication.

Design and Size Constraints

The components to be brazed must fit within the vacuum chamber. This places practical limits on the size of the assemblies that can be produced. The design must also allow for the proper placement of the braze alloy and ensure all joint areas reach a uniform temperature.

The Production Advantage: Repeatability and Efficiency

For the right applications, vacuum brazing provides unparalleled efficiency and consistency, making it ideal for scaling production.

Automated and Repeatable Results

Once a brazing profile (heating rate, temperature, cooling rate) is developed, it can be executed by the furnace's computer with perfect repeatability. This eliminates operator variability and ensures every component in a production run meets the exact same quality standard.

Single-Cycle Processing

A major efficiency gain comes from process consolidation. It is possible to combine brazing, hardening, and even age-hardening treatments into a single furnace cycle. This saves enormous amounts of time, energy, and material handling compared to performing each step separately.

Making the Right Choice for Your Application

When evaluating vacuum brazing, align the process benefits with your primary project goal.

- If your primary focus is maximum thermal performance: Vacuum brazing is the superior choice for creating void-free joints that ensure the most efficient heat transfer possible.

- If your primary focus is mechanical precision and reliability: The low-stress, distortion-free nature of the process guarantees that components maintain their precise dimensions and structural integrity.

- If your primary focus is production efficiency at scale: The ability to combine multiple thermal processes and deliver highly repeatable results makes it ideal for high-volume manufacturing of critical components.

Ultimately, adopting vacuum brazing is a strategic decision to build more reliable and higher-performing electronic systems from the component level up.

Summary Table:

| Benefit | Description |

|---|---|

| Eliminates Contamination | No flux or oxides, ensuring clean, strong joints without post-cleaning |

| Superior Thermal Conductivity | Flux-free, void-free joints allow unimpeded heat transfer for better cooling |

| Minimizes Distortion and Stress | Uniform heating and cooling prevent warping, maintaining precise dimensions |

| Joins Dissimilar Materials | Enables bonding of materials like copper and aluminum for optimized components |

| High Repeatability and Efficiency | Automated processes ensure consistent quality and allow combined thermal treatments in one cycle |

Ready to enhance your electronics with reliable vacuum brazing solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're focused on thermal management, mechanical precision, or scaling production, KINTEK delivers efficient, repeatable results for high-value electronics. Contact us today to discuss how our expertise can benefit your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance