At its core, a modern Zirconia Dental Sintering Furnace supports user-defined programs by providing an intuitive touch-screen interface that allows technicians to create new heating cycles from scratch or modify existing presets. This gives the lab complete control over the sintering curve—the precise sequence of temperature changes and holding times—to meet the exact specifications of any zirconia material.

The true value of user-defined programs is not just customization, but empowerment. It shifts control from a rigid, one-size-fits-all process to a flexible system where technicians can precisely match the sintering cycle to the unique requirements of diverse materials, ensuring optimal strength, aesthetics, and efficiency.

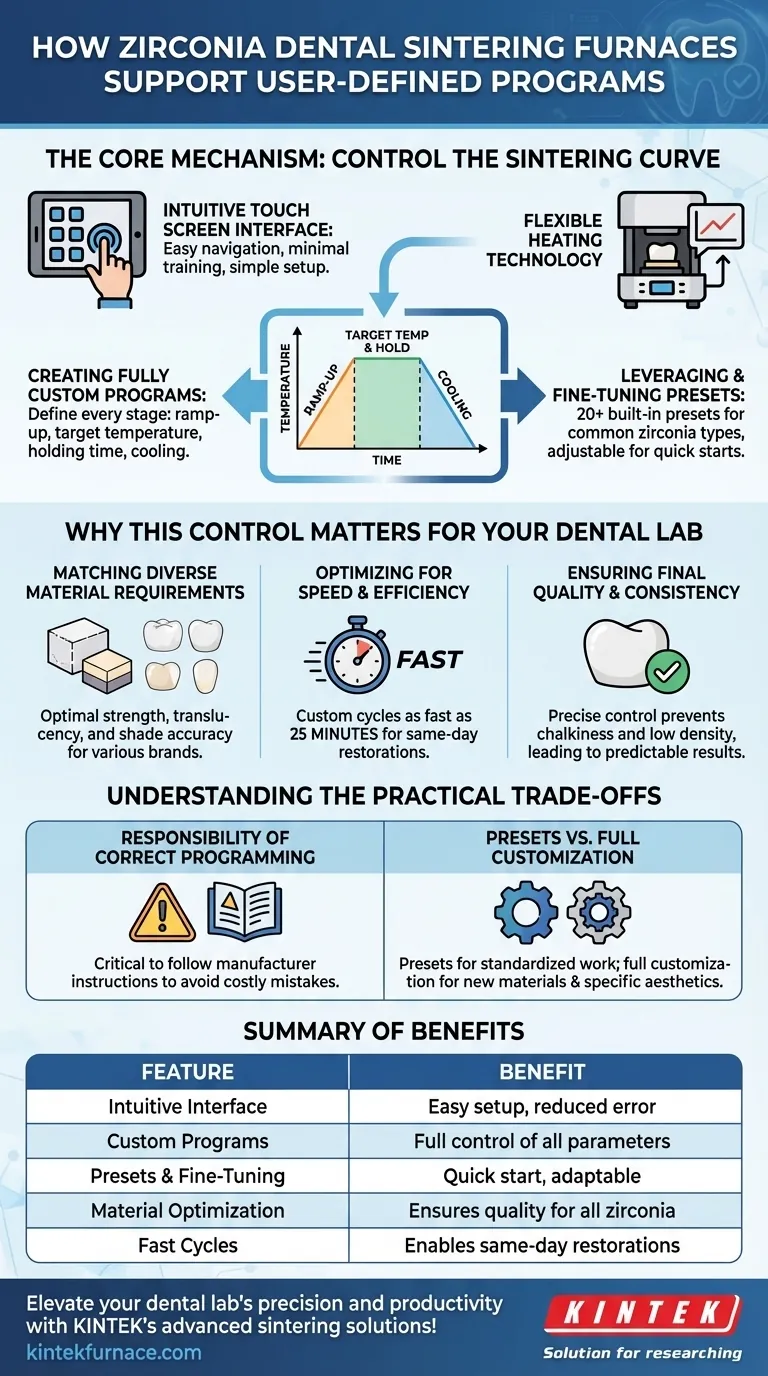

The Core Mechanism: How You Control the Sintering Curve

The ability to define sintering programs is enabled by a combination of user-friendly software and flexible heating technology. This system is designed to be both powerful for experts and accessible for daily use.

An Intuitive Touch Screen Interface

The furnace is operated via a touch screen, which is designed for easy navigation and requires minimal training. This interface is the gateway to all programming functions.

Customer feedback consistently highlights that setting up and adjusting cycles is simple and straightforward, reducing the potential for operator error and increasing lab efficiency.

Creating Fully Custom Programs

The system allows users to "independently arrange sintering curves." This means you can define every stage of the heat treatment process from a blank slate.

This includes setting the temperature ramp-up rate (how fast it heats up), the target temperature, the holding time at that peak temperature, and the cooling sequence.

Leveraging and Fine-Tuning Presets

For convenience, these furnaces come with built-in preset heating programs, often 20 or more. These presets are designed for common zirconia types and standard workflows.

Operators can quickly select a preset and then fine-tune the parameters as needed. This provides a safe and efficient starting point, saving time compared to building a new program for every case.

Why This Control Matters for Your Dental Lab

Flexible programming is not a minor feature; it is a critical capability that directly impacts the quality of your restorations and the productivity of your lab.

Matching Diverse Material Requirements

Different zirconia brands and types (e.g., high-translucency for anteriors vs. high-strength for bridges) have unique heat treatment requirements recommended by the manufacturer.

User-defined programs ensure you can perfectly match these specifications, which is essential for achieving the intended translucency, shade accuracy, and flexural strength of the final restoration.

Optimizing for Speed and Efficiency

The ability to create custom cycles allows labs to optimize for speed when necessary. For example, some furnaces can complete a full sintering cycle in as little as 25 minutes using a specific "fast" program.

This allows labs to offer same-day restorations and manage urgent cases without compromising their standard workflow.

Ensuring Final Quality and Consistency

Precise control over the sintering process is the final step in guaranteeing the integrity of a zirconia restoration. A custom-tailored curve prevents issues like chalkiness, low density, or poor aesthetics that can result from improper heating.

This leads to more consistent, predictable results and fewer costly remakes.

Understanding the Practical Trade-offs

While powerful, the responsibility for creating and managing custom programs rests with the lab technician.

The Responsibility of Correct Programming

With complete control comes the responsibility to use it correctly. An improperly designed sintering curve can easily ruin an entire batch of restorations, wasting time and expensive materials.

It is critical to always follow the zirconia manufacturer's instructions when creating or modifying a program. The furnace provides the tool; the material science provides the rules.

Presets vs. Full Customization

The choice between using a preset and a fully custom program depends on the task. Presets are ideal for high-volume, standardized work with familiar materials.

Full customization is best reserved for new materials, troubleshooting, or when trying to achieve a specific, non-standard aesthetic result under controlled conditions.

How to Apply This to Your Lab

Your approach to using these features should align directly with your lab's primary goals.

- If your primary focus is efficiency and throughput: Master the art of selecting the correct preset and making minor "fine-tuning" adjustments. This will cover the vast majority of your cases quickly and reliably.

- If your primary focus is quality with diverse materials: Invest time in learning how to build and save custom programs from scratch based on manufacturer data sheets. This will be your key to unlocking the full potential of specialty zirconia.

- If you are new to digital dentistry: Rely exclusively on the built-in presets that match your chosen zirconia brand's guidelines. This is the safest path to achieving consistent, successful results as you build experience.

Ultimately, this level of control transforms the furnace from a simple appliance into a precision instrument that directly contributes to superior patient outcomes.

Summary Table:

| Feature | Benefit |

|---|---|

| Intuitive Touch-Screen Interface | Easy program setup and modification, reducing operator error |

| Custom Program Creation | Full control over ramp-up, peak temperature, holding time, and cooling |

| Preset Programs with Fine-Tuning | Quick start with 20+ presets, adaptable for efficiency |

| Material-Specific Optimization | Ensures strength, translucency, and shade accuracy for diverse zirconia types |

| Fast Cycle Options | Enables same-day restorations with cycles as short as 25 minutes |

Elevate your dental lab's precision and productivity with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces tailored for dental labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our zirconia sintering furnaces can optimize your workflows and deliver superior patient outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab