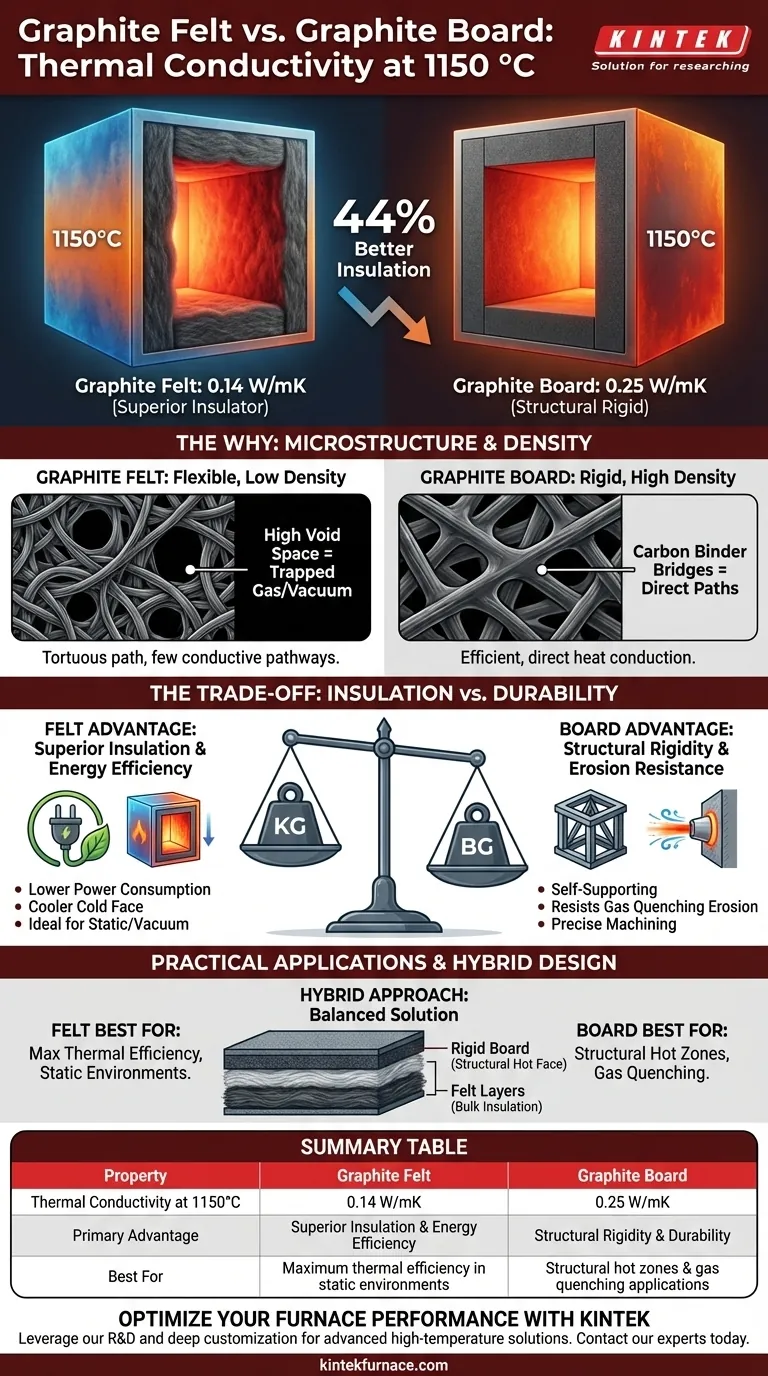

At 1150 °C, graphite felt is a significantly better insulator than graphite board. The thermal conductivity of graphite felt at this temperature is 0.14 W/mK, while graphite board measures 0.25 W/mK. This means that for a given thickness, graphite felt reduces heat transfer by approximately 44% compared to rigid graphite board, making it the more energy-efficient choice from a purely thermal perspective.

The decision between graphite felt and board is not simply about which is a better insulator. It is a fundamental engineering trade-off between the superior thermal performance of flexible felt and the structural rigidity and durability of rigid board.

Why Felt and Board Have Different Thermal Properties

The dramatic difference in thermal performance stems directly from the structure and density of each material. Both originate from similar carbon fibers, but their final form dictates how effectively they can block heat.

The Structure of Graphite Felt

Graphite felt is a soft, flexible mat composed of intertwined, randomly oriented carbon fibers. This structure creates a high percentage of void space within the material.

In a vacuum or inert gas environment, these voids are crucial. Heat transfer through the material is minimized because it must navigate a tortuous path through thin fibers, with very few direct conductive pathways. The trapped gas (or vacuum) in the voids acts as the primary insulator.

The Structure of Graphite Board

Graphite board is a rigid product made by taking graphite felt and infiltrating it with a carbon-based binder, which is then cured at high temperatures. This process "glues" the fibers together.

This binder adds density and creates solid carbon bridges between the fibers. These bridges provide direct, efficient pathways for heat to conduct through the material, which is why its thermal conductivity is significantly higher than that of untreated felt.

The Role of Density

Ultimately, the difference comes down to density. Graphite felt has a very low density, maximizing void space and minimizing solid material available for heat conduction.

Graphite board is intentionally made denser to achieve mechanical strength and rigidity. This increase in density directly corresponds to an increase in thermal conductivity, making it a less effective insulator.

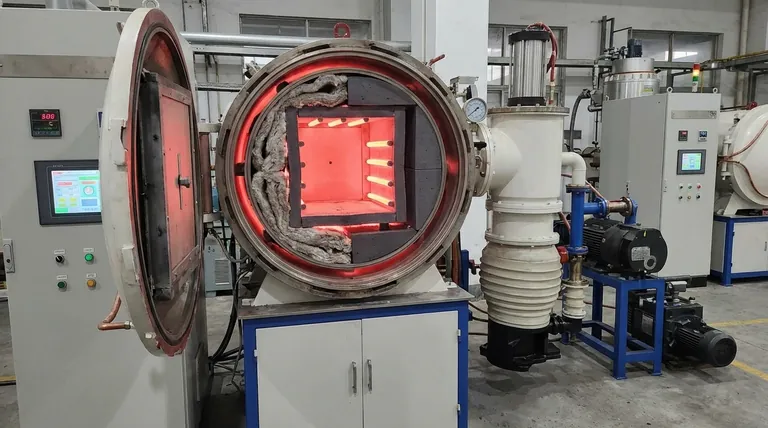

Practical Implications in High-Temperature Furnaces

This difference in conductivity has direct consequences for the performance and operating costs of high-temperature equipment, such as vacuum furnaces.

Energy Efficiency

A furnace insulated with graphite felt will require less power to maintain its target temperature compared to an identical furnace insulated with graphite board. The 44% lower thermal conductivity directly translates to reduced energy loss through the furnace walls.

Hot Face and Cold Face Temperatures

With felt's superior insulation, the temperature on the outer shell of the furnace (the "cold face") will be lower. This improves operator safety and further reduces energy waste into the surrounding facility.

Structural vs. Insulating Layers

In practice, many furnace hot zones are designed with a hybrid approach. A dense inner layer (like board) is used for its structural integrity, while the outer layers consist of lower-density felt to provide the bulk of the insulation.

Understanding the Trade-offs: Insulation vs. Durability

Choosing the right material requires understanding its mechanical limitations just as much as its thermal properties.

Mechanical Strength and Rigidity

Graphite board is the clear winner for mechanical strength. It is self-supporting, can be precisely machined, and can be used to construct the entire hot zone structure, including element supports. Felt is fragile and requires a separate support structure to hold it in place.

Resistance to Gas Flow

In applications with high-velocity gas flow, such as rapid gas quenching, the surface of soft felt can be easily eroded, shedding fibers that can contaminate the furnace and the workload. The rigid, bonded surface of graphite board is far more resistant to this type of erosion.

Handling and Installation

Felt is flexible and can easily conform to curved or irregular surfaces. However, it is delicate and can generate dust during installation. Board is easier to handle as pre-cut panels but is brittle and can crack if impacted or subjected to thermal shock without proper design considerations.

Making the Right Choice for Your Application

Your final decision should be based on the primary operational demands of your specific high-temperature process.

- If your primary focus is maximum thermal efficiency and lower energy costs: Choose graphite felt for its superior insulating properties, especially in static vacuum or low-pressure inert gas environments.

- If your primary focus is structural integrity, ease of assembly, or resistance to gas erosion: Choose graphite board, accepting the modest penalty in thermal performance for its crucial mechanical robustness.

- If you need a balanced, high-performance solution: Use a hybrid design, employing a rigid board or composite hot face for durability and backing it with multiple layers of felt for optimal insulation.

Ultimately, the best choice aligns the material's physical properties with the specific mechanical and thermal demands of your process.

Summary Table:

| Property | Graphite Felt | Graphite Board |

|---|---|---|

| Thermal Conductivity at 1150°C | 0.14 W/mK | 0.25 W/mK |

| Primary Advantage | Superior Insulation & Energy Efficiency | Structural Rigidity & Durability |

| Best For | Maximum thermal efficiency in static environments | Structural hot zones & gas quenching applications |

Optimize your furnace's performance and energy efficiency with the right graphite insulation.

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Whether your priority is the superior insulation of Graphite Felt or the structural integrity of Graphite Board, our product line—including Muffle, Tube, Vacuum & Atmosphere Furnaces—is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact our experts today to discuss the ideal insulation strategy for your application.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?