At its core, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a sophisticated manufacturing process used to apply ultra-durable, biocompatible coatings onto medical devices. This technology allows for the creation of diamond-like carbon (DLC) films that dramatically reduce friction and wear on implants, leading to improved longevity and better patient outcomes.

MPCVD's primary contribution is not just creating a coating, but enabling precise control over that coating's properties. This allows engineers to tailor a device's surface for specific biological interactions, transforming a standard implant into a high-performance, integrated component.

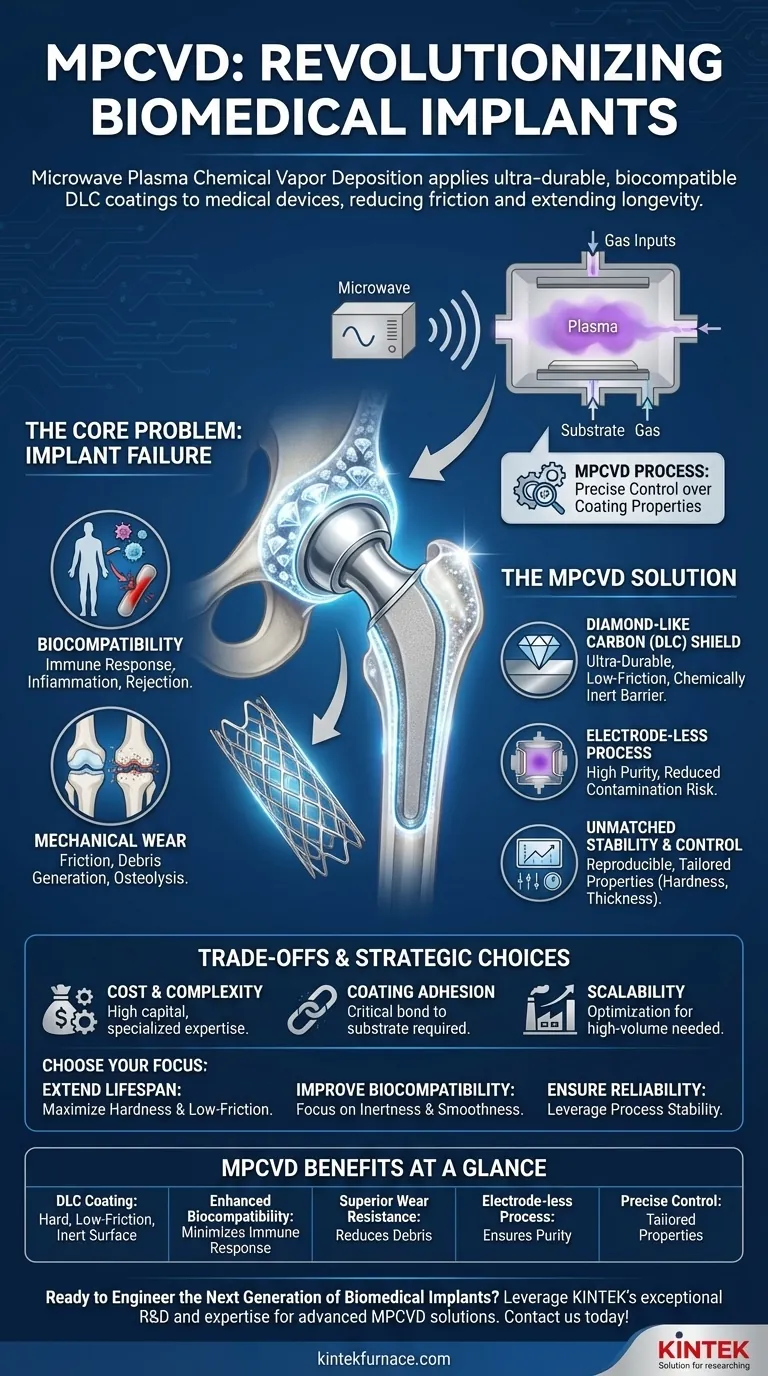

The Core Problem MPCVD Solves: Implant Failure

The long-term success of any medical implant, from a hip replacement to a cardiovascular stent, is threatened by two fundamental challenges: the body's reaction to a foreign object and mechanical wear over time.

The Challenge of Biocompatibility

The human body's immune system is designed to attack foreign materials. An implant can trigger inflammation or be encapsulated by fibrous tissue, leading to pain, device loosening, and eventual failure. A truly biocompatible surface must appear inert to the body.

The Issue of Mechanical Wear

Articulating joints, like knee or hip implants, are under constant stress and friction. This mechanical wear generates microscopic debris particles from the implant material. These particles can cause inflammation, bone loss (osteolysis), and ultimately, the need for revision surgery.

How MPCVD Creates a Superior Solution

MPCVD directly addresses these failure modes by depositing a thin, robust layer of diamond-like carbon (DLC) onto the implant's surface. This process gives the implant properties it would not otherwise possess.

Creating a Diamond-Like Carbon Shield

DLC is an amorphous material with a unique combination of diamond-hard and graphite-slick properties. This coating creates an exceptionally smooth and chemically inert barrier between the implant and the body.

The result is a surface that is both highly biocompatible, minimizing immune response, and extremely wear-resistant, drastically reducing friction and the generation of harmful debris.

The Advantage of an Electrode-less Process

A key feature of MPCVD is that it uses microwave energy, not electrical electrodes, to generate the plasma needed for deposition. This electrode-less design is critical for biomedical applications.

It significantly reduces the risk of contamination from electrode material, ensuring the purity and safety of the final implant coating.

Unmatched Stability and Control

The MPCVD method is known for its stability and reproducibility. It allows for continuous, long-duration deposition runs without a decline in the quality of the film.

This process control means that the properties of the DLC coating—such as its hardness, thickness, and smoothness—can be precisely tailored for a specific application. A coating for a high-wear hip joint can be optimized differently from one on a cardiovascular stent.

Understanding the Trade-offs and Considerations

While powerful, MPCVD is an advanced manufacturing technique with specific requirements that must be managed for successful implementation.

Cost and Complexity

MPCVD systems represent a significant capital investment and require specialized expertise to operate and maintain. The cost of the process is a key factor when evaluating it for a particular product.

Coating Adhesion

The single most critical factor for a coated implant's success is the adhesion of the coating to the substrate. A DLC film is useless if it delaminates. Significant process development is required to ensure a permanent bond between the coating and the underlying implant material (e.g., titanium or cobalt-chrome).

Scalability and Throughput

While the process is scalable, transitioning from laboratory research to high-volume manufacturing requires careful optimization. Maintaining consistent quality across larger substrates or for mass production is a primary engineering challenge that must be addressed.

Making the Right Choice for Your Application

Your specific goal will determine which benefit of MPCVD is most critical to leverage.

- If your primary focus is extending implant lifespan: Leverage MPCVD to create a hard, low-friction DLC coating that minimizes mechanical wear and debris generation.

- If your primary focus is improving patient biocompatibility: Utilize the chemically inert and ultra-smooth surface created by MPCVD to reduce inflammation and adverse tissue reactions.

- If your primary focus is manufacturing reliability: Capitalize on the stability and reproducibility of the MPCVD process to ensure consistent, high-quality coatings that meet stringent regulatory standards.

Ultimately, MPCVD provides the precise control needed to engineer the next generation of safer and more durable biomedical implants.

Summary Table:

| MPCVD Contribution | Key Benefit |

|---|---|

| Diamond-Like Carbon (DLC) Coating | Creates a hard, low-friction, and chemically inert surface. |

| Enhanced Biocompatibility | Minimizes immune response and inflammation by appearing inert to the body. |

| Superior Wear Resistance | Drastically reduces mechanical wear and generation of harmful debris particles. |

| Electrode-less Process | Ensures high-purity coatings, free from electrode material contamination. |

| Precise Process Control | Allows tailoring of coating properties (hardness, thickness) for specific applications. |

Ready to Engineer the Next Generation of Biomedical Implants?

Leverage KINTEK's exceptional R&D and in-house manufacturing expertise to integrate advanced MPCVD solutions into your medical device development. Our high-temperature furnace systems, including specialized CVD/PECVD configurations, are complemented by strong deep customization capabilities to precisely meet your unique coating requirements for implants, stents, and other critical devices.

Contact KINTEL today to discuss how our technology can help you create safer, more durable, and high-performance medical implants.

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More