At their core, vacuum furnaces achieve significant energy efficiency through their fundamental operating principle: removing the atmosphere. By creating a vacuum, these furnaces drastically reduce the primary ways heat is lost in conventional systems, allowing energy to be focused directly on the workpiece for faster, more efficient processing.

A vacuum furnace's efficiency is not just an add-on feature; it is an inherent result of its design. The vacuum minimizes heat loss, superior insulation retains energy, and precise controls prevent waste, leading to lower operating costs and a cleaner process.

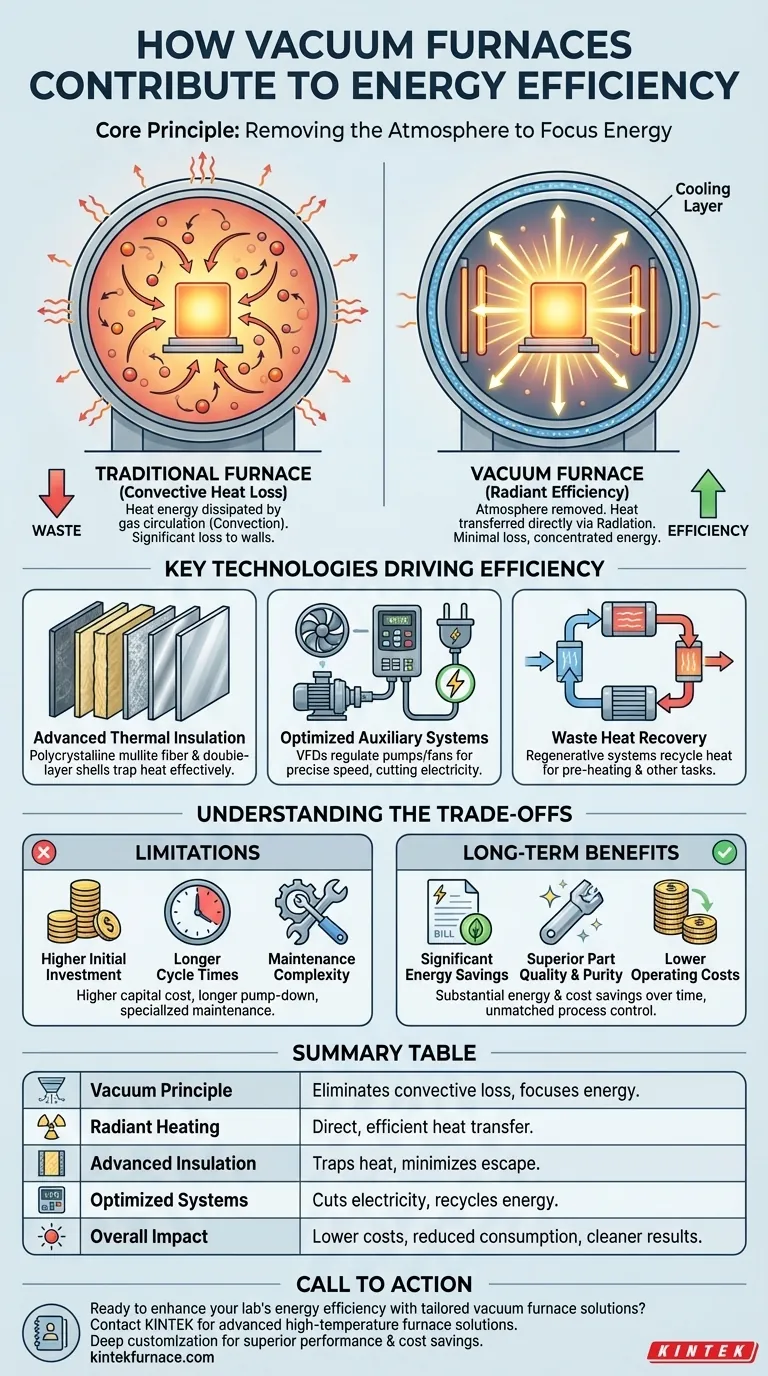

The Core Principle: How a Vacuum Reduces Energy Waste

The primary energy savings in a vacuum furnace come from manipulating the physics of heat transfer. By removing air and other gases, you eliminate the main pathways for energy to escape.

Minimizing Convective Heat Loss

In a traditional furnace, heated gas molecules circulate, transferring thermal energy away from the workpiece and toward the furnace walls in a process called convection.

A vacuum is an excellent insulator precisely because it has very few molecules. By removing the air, you remove the medium for convective heat transfer, ensuring the vast majority of the heat energy remains directed at the part.

Enabling Efficient Radiant Heating

With convection largely eliminated, thermal radiation becomes the dominant mode of heat transfer.

Heating elements radiate energy directly to the workpiece, which is a highly efficient and uniform method of heating. This direct line-of-sight energy transfer minimizes waste and ensures predictable, repeatable results.

Key Technologies Driving Efficiency

Beyond the vacuum itself, modern furnaces incorporate specific technologies designed to conserve and optimize energy use.

Advanced Thermal Insulation

The furnace chamber is lined with high-performance insulation materials, such as polycrystalline mullite fiber.

This material has extremely low thermal conductivity, meaning it is very effective at trapping heat inside the hot zone. Features like double-layer furnace shells with air cooling further prevent energy from escaping into the surrounding environment.

Optimized Auxiliary Systems

Energy efficiency extends to the systems that support the furnace's operation.

Modern vacuum furnaces often use Variable Frequency Drives (VFDs) on pumps and cooling fans. VFDs allow these motors to run at the precise speed required, drastically cutting electricity consumption compared to older systems that run at full power constantly.

Waste Heat Recovery

Some advanced designs incorporate regenerative cooling systems or other waste heat recovery technologies.

These systems capture heat from exhaust or cooling cycles and recycle it, pre-heating components or performing other tasks. This reuse of energy that would otherwise be lost further improves the overall efficiency of the operation.

Understanding the Trade-offs

While highly efficient, vacuum furnaces are not the universal solution for every heating application. A clear-eyed view of their limitations is essential.

Higher Initial Investment

Vacuum furnaces represent a significant capital expense. The cost of the vacuum chamber, pumping systems, and sophisticated controls is substantially higher than that of most conventional atmosphere furnaces.

Longer Cycle Times

Achieving a deep vacuum requires time. The "pump-down" phase adds to the total cycle time, which can impact overall throughput, especially in high-volume production environments.

Maintenance Complexity

High-vacuum systems demand specialized knowledge for maintenance. Seals, pumps, and instrumentation must be kept in pristine condition to ensure performance, which can increase the complexity and cost of upkeep compared to simpler systems.

Making the Right Choice for Your Operation

Selecting the right furnace technology requires balancing energy efficiency against your specific production goals, material requirements, and budget.

- If your primary focus is part quality and purity: A vacuum furnace is the superior choice, as it prevents surface oxidation and contamination, and the energy efficiency is a significant added benefit.

- If your primary focus is minimizing long-term operating costs: The substantial energy savings of a vacuum furnace can provide a strong return on the initial investment over the life of the equipment.

- If your primary focus is high-volume, low-cost throughput: The longer cycle times and high initial cost of a vacuum furnace may make a continuous atmosphere furnace a more practical choice.

Ultimately, a vacuum furnace offers a powerful combination of process control and energy efficiency that is unmatched for demanding applications.

Summary Table:

| Aspect | Contribution to Energy Efficiency |

|---|---|

| Vacuum Principle | Eliminates convective heat loss by removing air, focusing energy on the workpiece. |

| Radiant Heating | Enables direct, efficient heat transfer via radiation, minimizing waste. |

| Advanced Insulation | Uses materials like polycrystalline mullite fiber to trap heat effectively. |

| Optimized Systems | Incorporates VFDs and waste heat recovery to cut electricity use and recycle energy. |

| Overall Impact | Lowers operating costs, reduces energy consumption, and ensures cleaner, repeatable results. |

Ready to enhance your lab's energy efficiency with tailored vacuum furnace solutions?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior performance and cost savings.

Contact us today to discuss how our energy-efficient furnaces can benefit your operation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion