At their core, customized vacuum furnaces achieve remarkable energy efficiency by combining the fundamental physics of a vacuum with advanced, purpose-built engineering. The vacuum environment itself drastically reduces heat loss by minimizing convection, while custom features like superior insulation, intelligent power controls, and heat recovery systems ensure that every watt of energy is used with maximum effectiveness.

The primary driver of energy efficiency in a vacuum furnace isn't just a single feature, but a core principle: a vacuum is a near-perfect insulator. Customization builds upon this foundation by adding specific technologies that minimize wasted energy and actively recapture process heat, leading to significant reductions in operational cost and environmental impact.

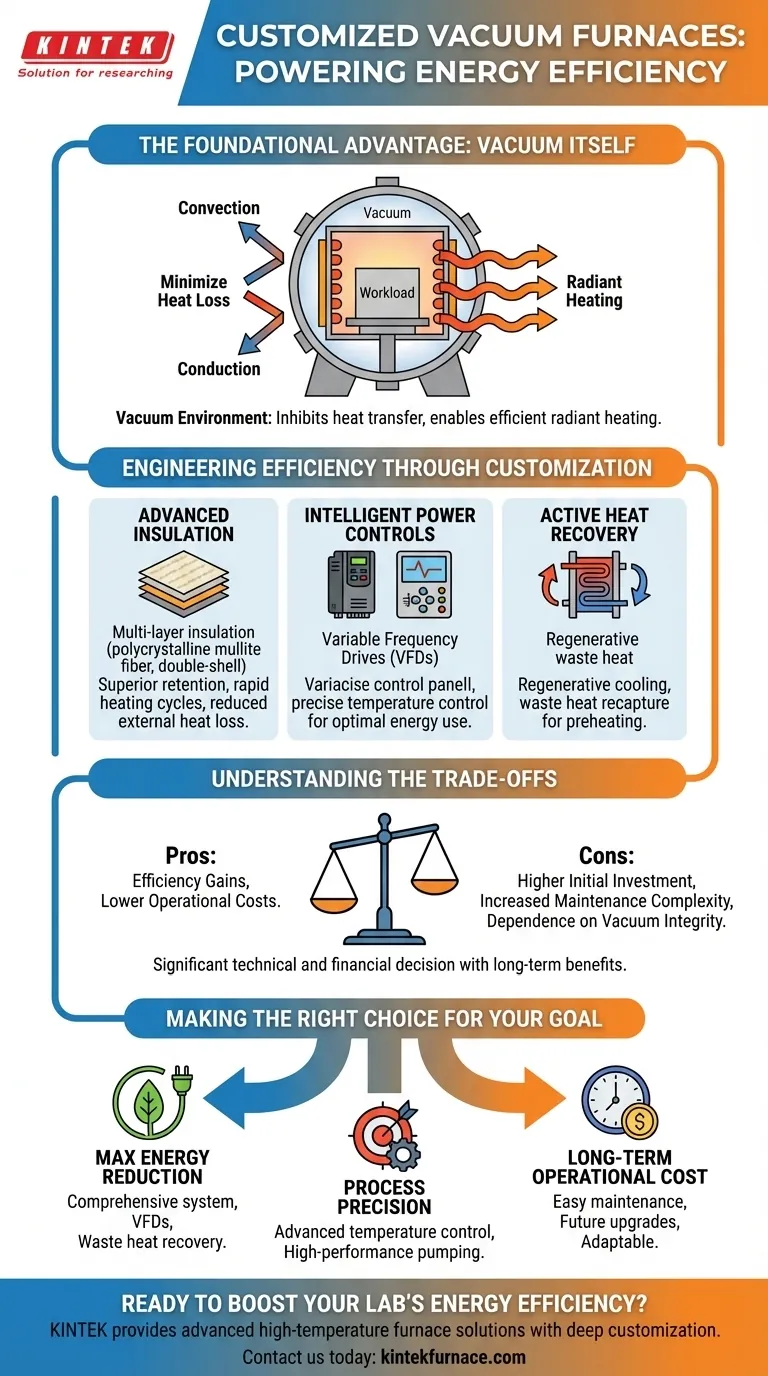

The Foundational Advantage: The Vacuum Itself

The efficiency of any furnace is defined by how well it directs heat into the workpiece and prevents it from escaping. A vacuum environment provides a powerful, inherent advantage that conventional furnaces cannot match.

Minimizing Heat Loss

In a normal atmosphere, heat escapes through conduction (transfer through contact) and convection (transfer through the movement of air or gas).

By removing nearly all gas molecules, a vacuum severely inhibits these two forms of heat transfer. This means the heat generated has nowhere to go but into the material being processed.

Enabling Efficient Radiant Heating

With convection and conduction minimized, heat transfer is dominated by thermal radiation.

This is a more direct and efficient way to heat the workload, as energy is transferred directly from the heating elements to the part surface without needing an intermediary gas.

Engineering Efficiency Through Customization

While the vacuum provides the foundation, customization unlocks the next level of energy savings. These engineered solutions are tailored to the specific process, ensuring no energy is wasted.

Advanced Insulation and Shell Design

The first line of defense against heat loss is physical insulation.

Custom furnaces utilize high-performance materials like polycrystalline mullite fiber, which has extremely low thermal conductivity. This enables rapid heating cycles while keeping heat locked inside the chamber.

Designs often incorporate double-layer furnace shells with advanced air insulation between them, creating an additional thermal break that further prevents heat from escaping into the facility.

Intelligent Power and Heat Management

Efficiency isn't just about preventing loss; it's also about using only the energy required.

Variable Frequency Drives (VFDs) are integrated with vacuum pumps and cooling fans. VFDs allow these components to run at the precise speed needed for the current stage of the process, drastically cutting the high energy consumption typical of running pumps at full power continuously.

Furthermore, precise temperature control systems ensure the furnace applies heat exactly when and where it's needed, preventing the energy waste associated with overshooting target temperatures.

Active Heat Recovery Systems

The most advanced systems don't just prevent heat loss—they actively recapture it.

Regenerative cooling systems and other waste heat recovery technologies can capture heat from exhaust gases or the cooling cycle. This recovered energy is then used to preheat incoming gas or other parts of the process, effectively recycling energy that would otherwise be lost.

Understanding the Trade-offs

While highly efficient, customized vacuum furnaces represent a significant technical and financial decision. Objectivity requires acknowledging the associated trade-offs.

Higher Initial Investment

Customization and advanced features like VFDs or heat recovery systems increase the upfront capital cost compared to a standard, off-the-shelf furnace. This investment is justified by lower long-term operational costs, but it must be factored into initial budgets.

Increased Maintenance Complexity

High-efficiency components, while reliable, can require specialized knowledge for maintenance and troubleshooting. A VFD or a heat recovery loop adds complexity compared to a basic furnace design, potentially requiring specific technician training.

Dependence on Vacuum Integrity

The core efficiency benefit hinges on the quality of the vacuum. This places a critical emphasis on the performance and maintenance of the vacuum pump system and the integrity of all chamber seals. Any leak degrades performance and negates the efficiency gains.

Making the Right Choice for Your Goal

The ideal furnace configuration depends entirely on your operational priorities. By matching features to your primary objective, you can ensure your investment delivers the maximum return.

- If your primary focus is maximum energy reduction: Prioritize a comprehensive system with high-quality insulation, VFDs on all major motors, and a waste heat recovery unit.

- If your primary focus is process precision and repeatability: Invest in advanced temperature control systems and a high-performance vacuum pumping system to ensure a stable, controllable environment.

- If your primary focus is long-term operational cost: Select a furnace designed for easy maintenance and future upgrades, ensuring it remains efficient and adaptable for years to come.

Ultimately, a customized vacuum furnace is an investment in controlled, efficient, and clean thermal processing.

Summary Table:

| Feature | Benefit |

|---|---|

| Vacuum Environment | Minimizes heat loss by reducing convection and conduction |

| Advanced Insulation | Uses materials like polycrystalline mullite fiber for superior heat retention |

| Intelligent Power Controls | Employs VFDs and precise temperature systems to optimize energy use |

| Heat Recovery Systems | Recaptures waste heat for reuse, improving overall efficiency |

| Custom Design | Tailored to specific processes, ensuring no energy is wasted |

Ready to boost your lab's energy efficiency with a tailored solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our customized vacuum furnaces can reduce your operational costs and environmental footprint!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity