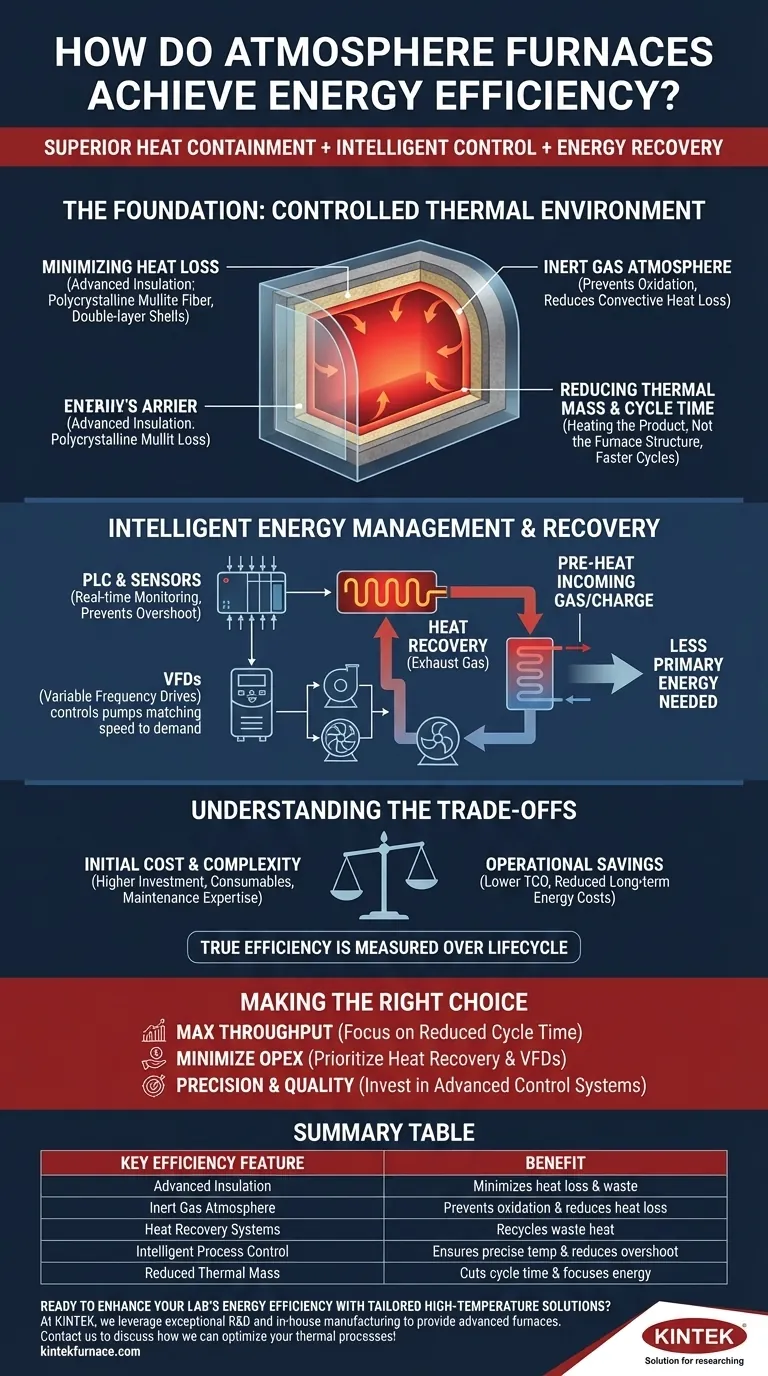

At their core, atmosphere furnaces achieve energy efficiency through a combination of superior heat containment, intelligent process control, and the recovery of otherwise wasted energy. By creating a sealed, controlled thermal environment, they minimize the primary sources of energy loss—unwanted chemical reactions, heat escaping to the surrounding area, and inefficient heating cycles—directing more energy directly into the workpiece.

The fundamental efficiency of an atmosphere furnace comes from isolating the heating process. Unlike traditional furnaces that waste energy heating ambient air and their own massive structures, atmosphere furnaces create a controlled system where energy is precisely applied, contained, and even recycled.

The Foundation: A Controlled Thermal Environment

The greatest energy savings are realized by fundamentally changing the heating environment. An atmosphere furnace is not just a hot box; it is a precisely engineered thermal system designed to prevent energy from escaping.

Minimizing Heat Loss Through Insulation

The first line of defense against energy waste is advanced insulation. Modern furnaces use high-quality materials like polycrystalline mullite fiber, which offers excellent thermal resistance while having low thermal mass.

This is often combined with design features like double-layer furnace shells and engineered air gaps. These create a thermal buffer, drastically reducing the amount of heat that radiates or conducts out of the furnace body.

The Role of an Inert Gas Atmosphere

Introducing an inert gas like nitrogen or argon serves two efficiency purposes. The first is preventing oxidation, an energy-consuming chemical reaction that occurs when hot metal is exposed to oxygen.

Second, the controlled atmosphere reduces convective heat loss. Circulating air in a traditional furnace constantly carries heat away from the parts and heating elements. A stable, controlled gas atmosphere minimizes this effect, keeping the heat where it belongs.

Reducing Thermal Mass and Cycle Time

A significant efficiency gain comes from operational design. Many atmosphere furnaces are designed to remain at temperature between batches.

Heating a 1,000-pound charge in a pre-heated chamber might take 60 minutes, whereas heating it from a cold start could take 90 minutes or more. By avoiding the need to repeatedly heat the furnace's entire structure—the insulation, shell, and supports—energy is spent almost exclusively on heating the product itself.

Intelligent Energy Management and Recovery

Beyond passive containment, modern furnaces actively manage and recycle energy to further boost efficiency. These systems ensure not a single watt is wasted.

Advanced Process Control

Programmable logic controllers (PLCs) and sophisticated sensors are the brains of an efficient furnace. They continuously monitor and adjust heating parameters in real time.

This prevents the common problem of temperature overshoot, ensuring the system uses only the precise amount of energy required to reach and maintain the target temperature for the specific charge.

Efficient Auxiliary Systems

A furnace is more than its heating chamber. Energy is also consumed by pumps, fans, and cooling systems.

The use of Variable Frequency Drives (VFDs) on motors for fans and pumps allows their speed to be matched to the exact demand of the cycle. This is far more efficient than the traditional approach of running motors at full speed and using dampers or valves to regulate flow.

Heat Recovery and Regeneration

Perhaps the most intelligent feature is the recovery of waste heat. Hot exhaust gases, which would otherwise be vented, are captured and passed through a heat exchanger.

This recovered energy is then used to pre-heat the incoming inert atmosphere gas or even the next material charge. This "regenerative" process significantly reduces the amount of primary energy needed from the main heating elements to reach the target temperature.

Understanding the Trade-offs

While highly efficient, atmosphere furnaces present considerations that must be weighed against their operational savings. True efficiency is measured over the equipment's entire lifecycle.

Initial Cost vs. Operational Savings

The advanced insulation, control systems, and gas handling equipment make atmosphere furnaces a higher initial investment than simpler, less efficient alternatives. The justification lies in a lower total cost of ownership (TCO) driven by reduced long-term energy and processing costs.

The Cost of Consumables

The inert gases used to create the controlled atmosphere are a continuous operational expense. The cost of nitrogen or argon must be factored into any calculation of overall efficiency and return on investment.

Maintenance Complexity

The sophisticated PLCs, sensors, and gas flow controls that enable high efficiency also require a higher level of maintenance expertise. A maintenance plan must account for the skills and time needed to keep these complex systems running optimally.

Making the Right Choice for Your Process

Selecting the right features depends on your specific production goals. Your definition of "efficiency" should guide your investment.

- If your primary focus is maximum throughput: Choose a furnace designed to maintain temperature between cycles, as this will have the most significant impact on reducing overall cycle time.

- If your primary focus is minimizing operational expenditure (OpEx): Prioritize systems with advanced heat recovery from exhaust gases and VFDs on all major auxiliary motors.

- If your primary focus is process precision and quality: Invest in a furnace with the most advanced programmable control system to ensure perfect, repeatable thermal profiles while inherently preventing energy waste from over- or under-shooting.

Ultimately, choosing the right furnace requires looking beyond the spec sheet and understanding how each efficiency feature aligns with your operational priorities.

Summary Table:

| Key Efficiency Feature | Benefit |

|---|---|

| Advanced Insulation | Minimizes heat loss and energy waste |

| Inert Gas Atmosphere | Prevents oxidation and reduces convective heat loss |

| Heat Recovery Systems | Recycles waste heat to pre-heat gases or materials |

| Intelligent Process Control | Ensures precise temperature management and reduces overshoot |

| Reduced Thermal Mass | Cuts cycle time and focuses energy on the workpiece |

Ready to enhance your lab's energy efficiency with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Atmosphere Furnaces, Muffle, Tube, Rotary, Vacuum, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering superior performance and cost savings. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment