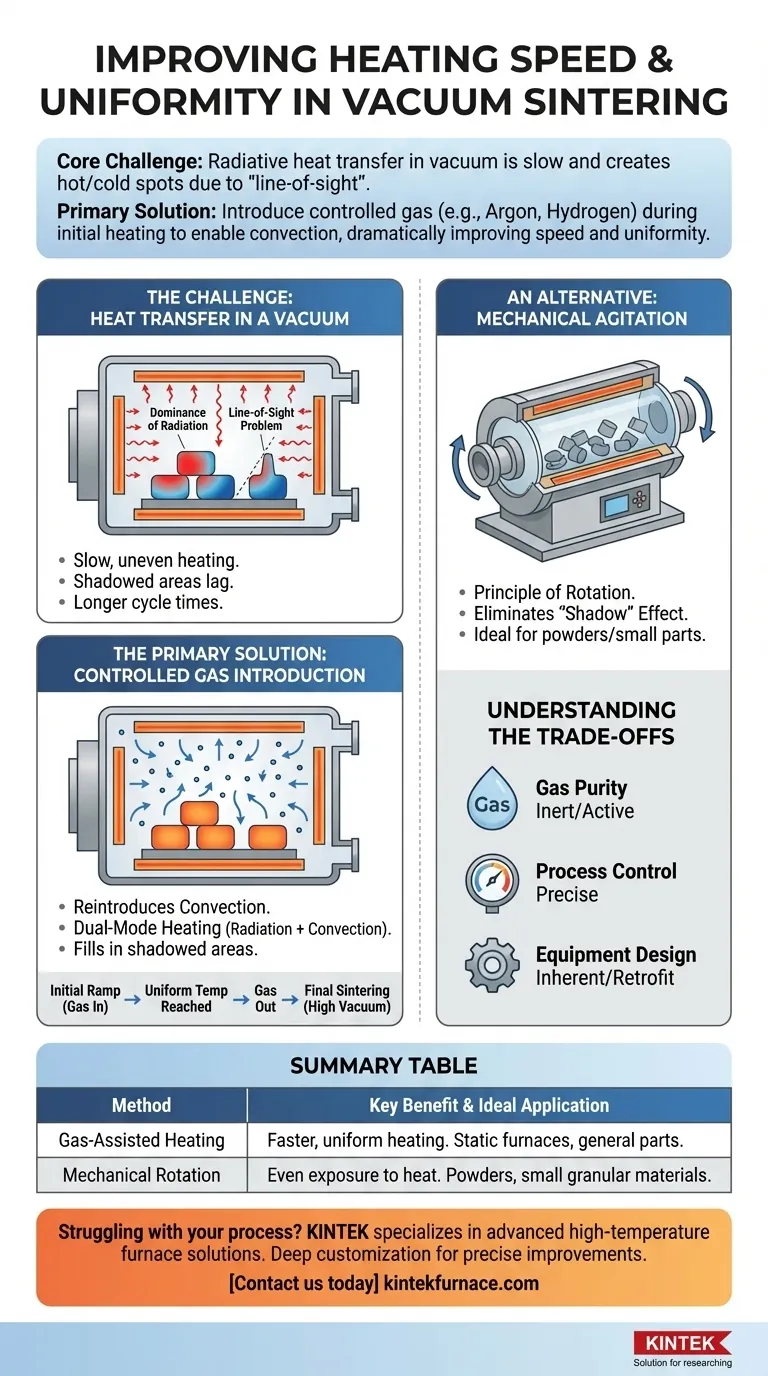

To significantly improve heating speed and temperature uniformity in vacuum sintering, the most effective method is to introduce a controlled amount of high-purity gas, such as argon or hydrogen, during the initial heating phase. This technique, often called "gas-assisted heating" or partial pressure heating, reintroduces convection into the furnace, overcoming the inherent limitations of heat transfer in a pure vacuum. For certain furnace designs, mechanical rotation of the furnace tube serves a similar purpose by ensuring all material surfaces are heated evenly.

The core challenge of vacuum heating is its sole reliance on radiative heat transfer, which is slow and creates hot and cold spots. By temporarily adding a gas, you enable convective heat transfer, which efficiently carries heat to all surfaces of the parts, dramatically increasing both heating speed and temperature uniformity.

The Fundamental Challenge: Heat Transfer in a Vacuum

To solve this problem, you must first understand why it occurs. A vacuum furnace heats differently than a standard atmospheric furnace, and this difference is the root of the issue.

The Dominance of Radiation

In a high vacuum, there are virtually no gas molecules to transfer heat. Therefore, heat can only travel from the heating elements to your parts via thermal radiation.

The "Line-of-Sight" Problem

Radiative heating is a "line-of-sight" process. Surfaces directly facing the heating elements get hot quickly, while surfaces that are shielded or in the "shadow" of other parts heat up much more slowly. This creates significant temperature differences across a single part and throughout the entire load.

The Consequence: Slow and Uneven Heating

This reliance on radiation alone is why heating is often slow and non-uniform. The process is limited by how quickly the shadowed areas can catch up, which relies on heat conducting through the material itself. This leads to longer cycle times and inconsistent material properties.

The Primary Solution: Controlled Gas Introduction

Introducing a gas is a simple but powerful process modification that directly addresses the physics of the problem.

Reintroducing Convection

When you backfill the furnace with a small amount of inert gas (e.g., argon) to a partial pressure, you re-enable convection. Gas molecules heat up upon contact with the elements, circulate throughout the chamber, and transfer that heat to all surfaces of your parts.

A Dual-Mode Heating System

This creates a highly efficient dual-mode system. You still have the power of radiation, but it is now augmented by convection, which fills in the gaps and heats the "shadowed" areas that radiation cannot reach.

Implementing the Process

This technique is typically used only during the initial temperature ramp-up. Once the parts have reached a uniform temperature near the sintering point, the gas is pumped out to re-establish the high vacuum required for the final sintering stage.

An Alternative: Mechanical Agitation

For specific applications, the furnace design itself can solve the uniformity problem.

The Principle of Rotation

In a rotary tube furnace, the entire furnace tube is slowly rotated by a motor. This is most common when sintering powders or small, granular materials.

Eliminating the "Shadow" Effect

By continuously tumbling the material, rotation ensures that all particles are exposed to the radiative heat source evenly over time. This mechanical action directly prevents local overheating and ensures a highly uniform final product.

Understanding the Trade-offs

While effective, these methods have considerations that must be managed for successful implementation.

Gas Purity and Reactivity

The gas you introduce must be high-purity to prevent contamination or unwanted chemical reactions. Inert gases like argon are used to avoid reactions, while active gases like hydrogen may be used intentionally as a reducing agent to clean part surfaces.

Process Control

Implementing gas-assisted heating requires a furnace system capable of precise pressure control. You must be able to introduce a specific partial pressure and then evacuate it efficiently at the right point in the cycle.

Equipment Design

Mechanical rotation is an inherent feature of the furnace. It cannot be retrofitted to a standard static furnace and is best suited for materials that can be tumbled without damage.

Applying the Right Technique for Your Goal

Your choice of method depends on your equipment and the specific issues you face.

- If your primary focus is improving an existing static furnace: The most practical solution is to implement a partial pressure gas backfill during the initial heating ramp to improve convection.

- If your primary focus is designing a new process for powders or small parts: A rotary tube furnace is an excellent choice that provides inherent temperature uniformity through mechanical means.

By understanding that the core challenge is overcoming the limitations of radiative heat transfer, you can confidently control your process to achieve faster, more uniform results.

Summary Table:

| Method | Key Benefit | Ideal Application |

|---|---|---|

| Gas-Assisted Heating | Improves convection for faster, uniform heating | Static furnaces, general parts |

| Mechanical Rotation | Ensures even exposure to heat sources | Powders, small granular materials |

Struggling with slow or uneven heating in your vacuum sintering? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise improvements in heating speed and temperature uniformity for your laboratory. Contact us today to discuss how we can optimize your sintering process and boost efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety