An in-office ceramic oven gives you direct, chairside control to correct open proximal contacts on crowns. By using a specialized add-on porcelain, you can apply material to the deficient contact area, fire it in the oven in a matter of minutes, and then contour it to perfection. This entire process occurs within the original seating appointment, completely eliminating the need for lab remakes and additional patient visits.

The core problem with an open contact is the delay and inefficiency it creates. An in-office oven transforms this from a multi-week problem involving lab communication into a ten-minute, single-appointment solution you control entirely.

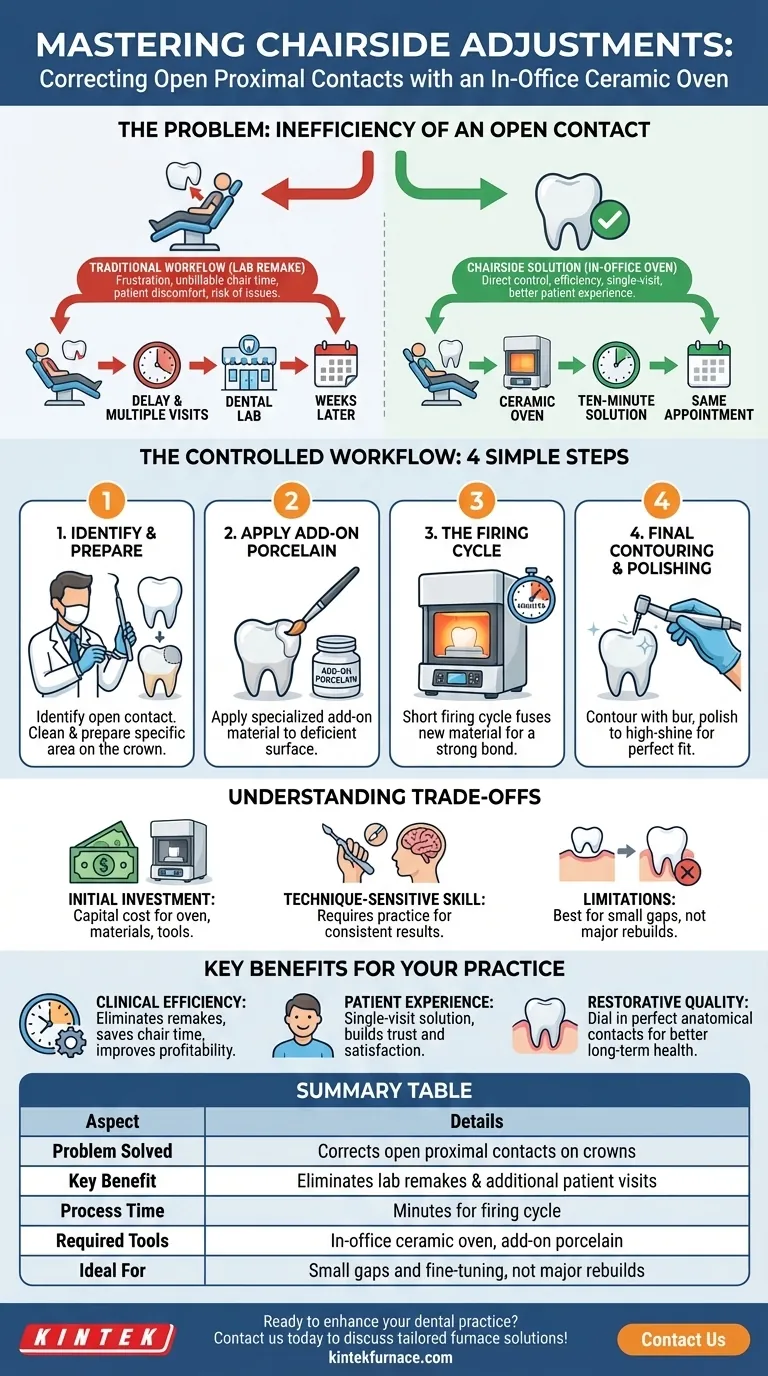

The Problem: The Inefficiency of an Open Contact

An open proximal contact is a common but disruptive clinical problem. It compromises the final restoration and forces a difficult choice between accepting a flawed result or initiating a time-consuming correction process.

The Traditional Workflow

Without a chairside oven, discovering an open contact at the seating appointment is highly inefficient. The only reliable option is to send the crown back to the dental laboratory.

This involves taking a new impression, articulating the issue to the lab technician, and scheduling the patient for a second delivery appointment weeks later. This delay frustrates the patient and consumes valuable, unbillable chair time.

The Clinical Consequences

Leaving an open contact is not a viable option. It inevitably leads to food impaction, which can cause patient discomfort, chronic gingival inflammation, and an increased risk of periodontal issues and recurrent caries.

The Chairside Solution: A Controlled Workflow

An in-office oven provides a direct, predictable solution that keeps the entire process under your clinical control. It turns a potential failure into a simple adjustment.

Step 1: Identify and Prepare the Crown

Once you identify the open contact, the crown is removed from the mouth. The specific contact area that needs the addition is cleaned and prepared according to the manufacturer's instructions for the add-on ceramic.

Step 2: Apply the Add-on Porcelain

A small amount of add-on porcelain is mixed into a paste. This material is carefully applied directly to the deficient contact surface of the crown, building it up slightly more than needed to allow for post-firing contouring.

Step 3: The Firing Cycle

The crown is placed into the ceramic oven. A short firing cycle, often just a few minutes, heats the crown and fuses the new add-on material to the existing porcelain. This creates a strong, monolithic bond.

Step 4: Final Contouring and Polishing

After the crown cools, the newly added porcelain is contoured with a fine diamond bur to create the ideal shape and contact pressure. It is then polished to a smooth, high-shine finish before the crown is permanently seated.

Understanding the Trade-offs

While powerful, incorporating this technique requires an understanding of its requirements and limitations. It is a tool for fine-tuning, not for large-scale fabrication.

The Initial Investment

The most obvious consideration is the capital investment in a high-quality ceramic oven. You must also factor in the ongoing cost of specialized add-on ceramic materials and any associated brushes or instruments.

A Technique-Sensitive Skill

While the process is straightforward, achieving consistently excellent results requires practice. Learning to apply the correct amount of material and contouring it effectively is a skill developed over time.

Limitations of Add-on Ceramics

This method is designed for closing small gaps. It is the perfect solution for a contact that is light or slightly open. It is not intended for rebuilding large, missing sections of a crown or correcting major fabrication errors.

Making the Right Choice for Your Goal

Integrating an in-office oven is a strategic decision about efficiency and clinical control. It empowers you to deliver a higher standard of care without relying on outside variables.

- If your primary focus is clinical efficiency: This tool virtually eliminates remake appointments for open contacts, saving hours of chair time and improving profitability.

- If your primary focus is patient experience: Solving the problem in a single visit is a massive value-add for the patient, building trust and satisfaction.

- If your primary focus is restorative quality: It gives you the ultimate power to dial in perfect anatomical contacts for every crown, ensuring better long-term periodontal health.

Ultimately, an in-office oven allows you to take direct ownership of the final restorative outcome.

Summary Table:

| Aspect | Details |

|---|---|

| Problem Solved | Corrects open proximal contacts on crowns |

| Key Benefit | Eliminates lab remakes and additional patient visits |

| Process Time | Minutes for firing cycle |

| Required Tools | In-office ceramic oven, add-on porcelain |

| Ideal For | Small gaps and fine-tuning, not major rebuilds |

Ready to enhance your dental practice with advanced ceramic solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored furnaces can streamline your chairside adjustments and boost efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab