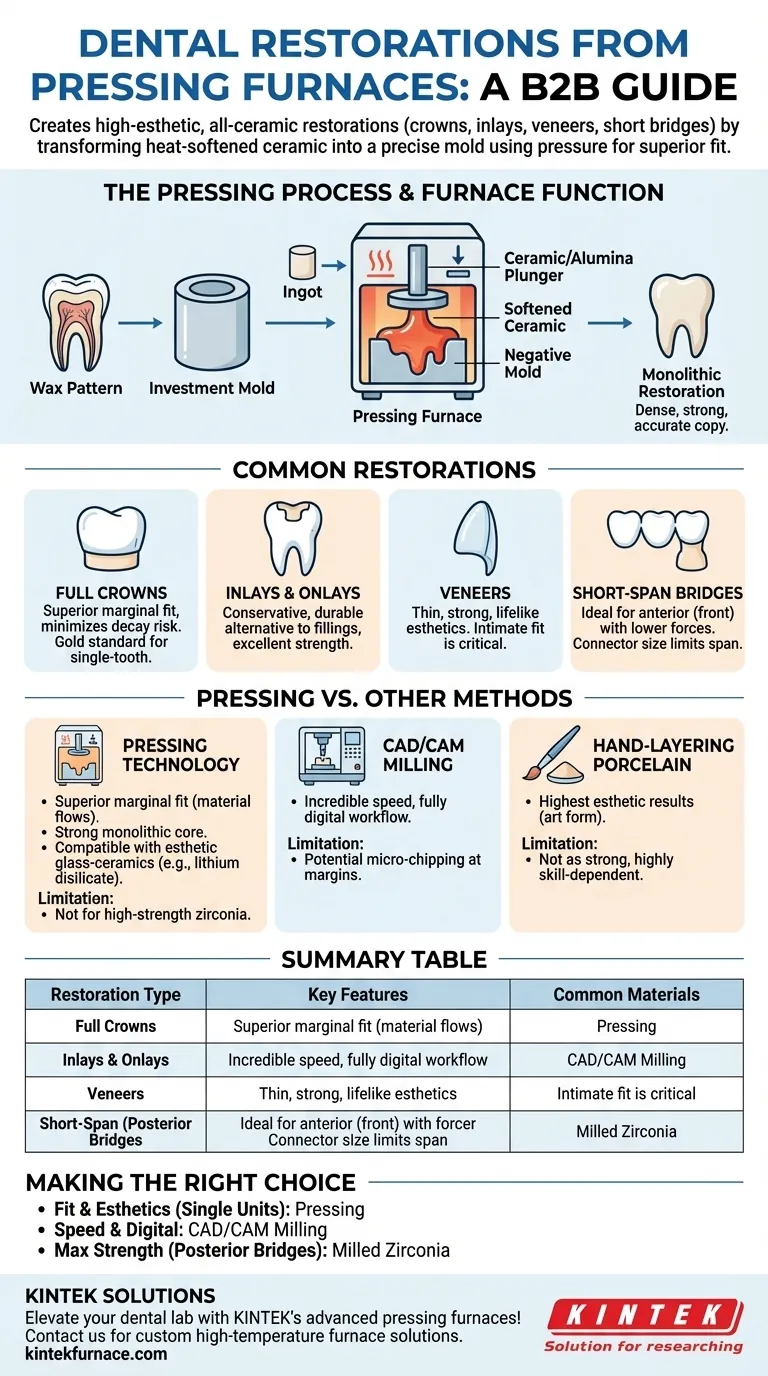

In essence, a pressing furnace is used to create a wide range of highly esthetic, all-ceramic dental restorations. The most common applications include single-tooth restorations like full crowns, inlays, onlays, and veneers, as well as short-span bridges. This technology relies on pressing heat-softened ceramic into a precise mold.

A pressing furnace enables the fabrication of strong, monolithic ceramic restorations with exceptional marginal fit. Its core function is to transform a wax pattern of a restoration into a final ceramic component through a process of heat and pressure.

A Foundational Overview of the Pressing Process

To understand the restorations a pressing furnace can create, you must first understand how it works. The technology is an evolution of the classic "lost-wax" casting technique used for decades in dentistry.

The "Lost-Wax" Principle

The process begins with a detailed wax model of the final restoration, known as a wax pattern. This pattern is attached to a sprue (a wax channel) and encased in a specialized plaster-like material called investment.

Once the investment hardens, the entire cylinder is placed into a burnout oven (which can be the pressing furnace itself) to eliminate the wax completely. This leaves behind a precise negative mold of the restoration.

The Role of the Furnace: Heat and Pressure

A ceramic ingot, typically made of materials like lithium disilicate or leucite-reinforced glass-ceramic, is placed into the investment mold.

The pressing furnace then heats the mold and the ingot to a specific temperature, causing the ceramic to become highly viscous (like thick honey). A ceramic or alumina plunger within the furnace then applies pressure, forcing the softened ceramic into every detail of the mold.

The Result: A Monolithic Restoration

After cooling, the investment is carefully removed, revealing a single, solid piece of ceramic—a monolithic restoration. This component is dense, strong, and an incredibly accurate copy of the original wax pattern. It is then finished with stains and glazes to achieve the final tooth shade and character.

Common Restorations Made with Pressing Technology

Pressing is a versatile technique, but it excels in specific clinical applications where fit and esthetics are paramount.

Full Crowns

Pressed ceramic crowns are a gold standard for single-tooth restorations. The process yields a crown with superior marginal integrity and internal adaptation to the prepared tooth, minimizing the risk of cement washout and secondary decay.

Inlays and Onlays

For more conservative restorations that replace only a portion of the tooth, pressed inlays and onlays are ideal. The strength of the monolithic ceramic provides a durable alternative to direct composite fillings or traditional metal castings.

Veneers

Pressing allows for the fabrication of very thin, yet strong, porcelain veneers. The accuracy of the process ensures an intimate fit against the tooth surface, which is critical for both bonding strength and achieving lifelike esthetics.

Short-Span Bridges

While not suitable for long-span bridges, pressing can be used for 3-unit bridges, particularly in the anterior (front) of the mouth where biting forces are lower. The connector size is a critical limiting factor for the strength of the final bridge.

Understanding the Trade-offs: Pressing vs. Other Methods

No single technique is perfect for every situation. Understanding the advantages and limitations of pressing is key to making informed decisions.

Pressing vs. CAD/CAM Milling

CAD/CAM milling involves subtracting a restoration from a solid block of ceramic using a computer-controlled machine. Milled restorations offer incredible speed and a fully digital workflow.

However, pressed restorations often exhibit a superior marginal fit out of the furnace because the material flows into place rather than being cut by a bur. Milling can sometimes introduce micro-chipping at the margins, which must be managed with careful polishing.

Pressing vs. Hand-Layering Porcelain

Traditional powder-and-liquid porcelain layering is an art form that allows a technician to build up a restoration in layers of different colors and translucencies. This can achieve the highest possible esthetic results.

The downside is that layered porcelain is not as strong as a monolithic pressed core and is highly dependent on the technician's skill. A common and effective technique is to press a strong monolithic core and then layer esthetic porcelain on top.

Material Limitations

The primary advantage of pressing is its compatibility with highly esthetic glass-ceramic materials. However, it cannot be used for high-strength materials like monolithic zirconia, which must be milled from a pre-sintered block and then fired in a sintering furnace to achieve its final strength.

Making the Right Choice for Your Goal

Selecting the correct fabrication method depends entirely on the clinical requirements of the case, including strength, esthetics, and location in the mouth.

- If your primary focus is the ultimate fit and esthetics for single crowns, veneers, inlays, or onlays: Pressing technology, especially with lithium disilicate, offers a premier combination of strength and beauty.

- If your primary focus is rapid turnaround and a fully digital workflow: CAD/CAM milling is the most efficient method for fabricating single-unit restorations.

- If your primary focus is maximum strength for a long-span posterior bridge: Milled monolithic zirconia remains the undisputed material of choice.

By understanding the distinct capabilities of the pressing furnace, you can better leverage its unique advantages to produce durable, predictable, and highly esthetic dental restorations.

Summary Table:

| Restoration Type | Key Features | Common Materials |

|---|---|---|

| Full Crowns | Superior marginal fit, minimizes decay risk | Lithium disilicate, Leucite-reinforced glass-ceramic |

| Inlays and Onlays | Conservative, durable alternative to fillings | Lithium disilicate, Leucite-reinforced glass-ceramic |

| Veneers | Thin, strong, lifelike esthetics | Lithium disilicate, Leucite-reinforced glass-ceramic |

| Short-Span Bridges | Ideal for anterior areas with lower forces | Lithium disilicate, Leucite-reinforced glass-ceramic |

Elevate your dental lab's capabilities with KINTEK's advanced pressing furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior fit, strength, and esthetics for restorations like crowns, veneers, and bridges. Contact us today to discuss how our tailored solutions can enhance your workflow and outcomes!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations