The primary containers used in vacuum tube furnaces are specially designed tubes made from either high-purity quartz or corundum (alumina). These tubes form the core reaction chamber and are sealed at both ends using stainless steel flanges to create an airtight environment for high-temperature processing under vacuum or a controlled atmosphere.

The choice between a quartz and a corundum tube is not arbitrary; it is a critical decision dictated by your experiment's maximum temperature, required heating and cooling rates, and the need for visual observation.

The Function of the Furnace Tube System

A vacuum tube furnace isn't just a heater; it's a controlled environment. The tube and its sealing components are what make this controlled environment possible.

The Core Reaction Chamber

The tube itself serves as the physical barrier separating your sample from the external heating elements and the ambient air. It contains the desired atmosphere—be it a high vacuum or a specific process gas—ensuring the purity of your experiment.

Creating a Sealed Environment

To achieve and maintain a vacuum or controlled atmosphere, the tube must be perfectly sealed. This is accomplished with stainless steel flanges fitted with O-rings, which clamp onto each end of the tube, creating an airtight system. These flanges also provide ports for vacuum pumps and gas inlets.

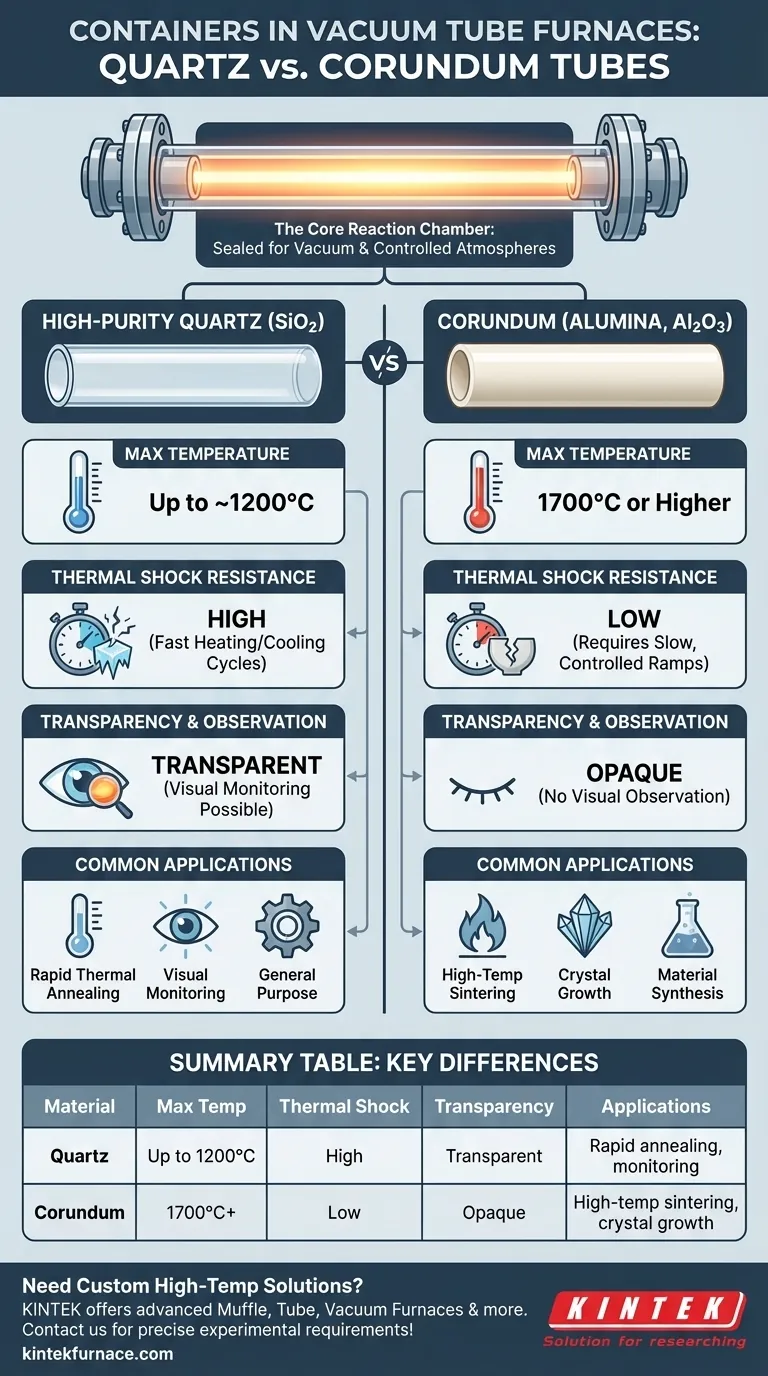

Comparing the Core Materials: Quartz vs. Corundum

The material of the tube is the most critical factor, as it determines the furnace's operational limits. The two standard options serve very different purposes.

High-Purity Quartz Tubes

Quartz is the most common material for general-purpose applications. Its primary advantage is its excellent thermal shock resistance, allowing for relatively fast heating and cooling cycles without cracking.

Furthermore, quartz is optically transparent. This is a significant benefit, as it allows you to visually monitor the sample during the heating process.

Corundum (Alumina) Tubes

Corundum, often referred to as alumina, is used when temperature requirements exceed the limits of quartz. These tubes are defined by their superior high-temperature stability, capable of operating at 1700°C or higher.

Unlike quartz, corundum is opaque, meaning you cannot observe the sample during processing. It is also more sensitive to thermal shock and requires slower, more controlled heating and cooling ramps.

Understanding the Trade-offs

Choosing the right tube involves balancing performance, operational constraints, and cost. Misunderstanding these trade-offs is a common source of experimental failure and equipment damage.

Temperature vs. Thermal Shock

This is the central trade-off. For temperatures up to approximately 1200°C, quartz provides operational flexibility with its tolerance for rapid temperature changes. For any process requiring temperatures above that, corundum is necessary, but you sacrifice the ability to heat or cool quickly.

Durability and Handling

While both materials are brittle ceramics, quartz is generally more forgiving of minor, rapid temperature fluctuations. Corundum tubes require careful programming of heating ramps to prevent thermal stress, which can lead to fractures and costly replacement.

Observation vs. Maximum Temperature

If visually inspecting your material's state (e.g., melting, color change) during the process is critical, quartz is your only option. If reaching the highest possible temperature is the goal, you must forgo this capability and use corundum.

Selecting the Right Tube for Your Application

Your experimental goal directly dictates the correct choice of container.

- If your primary focus is on processes below 1200°C, rapid thermal annealing, or requires visual monitoring: A quartz tube is the clear and cost-effective choice.

- If your primary focus is on high-temperature sintering, crystal growth, or material synthesis above 1200°C: A corundum (alumina) tube is required for its superior heat resistance.

Understanding the distinct properties of these materials empowers you to match your furnace's capabilities precisely to your experimental goals.

Summary Table:

| Material | Max Temperature | Thermal Shock Resistance | Transparency | Common Applications |

|---|---|---|---|---|

| Quartz | Up to 1200°C | High | Transparent | Rapid thermal annealing, visual monitoring |

| Corundum (Alumina) | 1700°C or higher | Low | Opaque | High-temperature sintering, crystal growth |

Need a custom high-temperature furnace solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental requirements are met precisely. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability