At its core, platinum is used in heating elements for its unique combination of an extremely high melting point, chemical inertness, and stable electrical properties. This allows it to operate reliably in high-temperature, corrosive environments where less robust materials would quickly degrade or contaminate the process.

Platinum is not chosen for its efficiency as a heater, but for its survivability. The decision to use it is driven by applications where process purity and operational reliability in extreme conditions are more critical than the initial material cost.

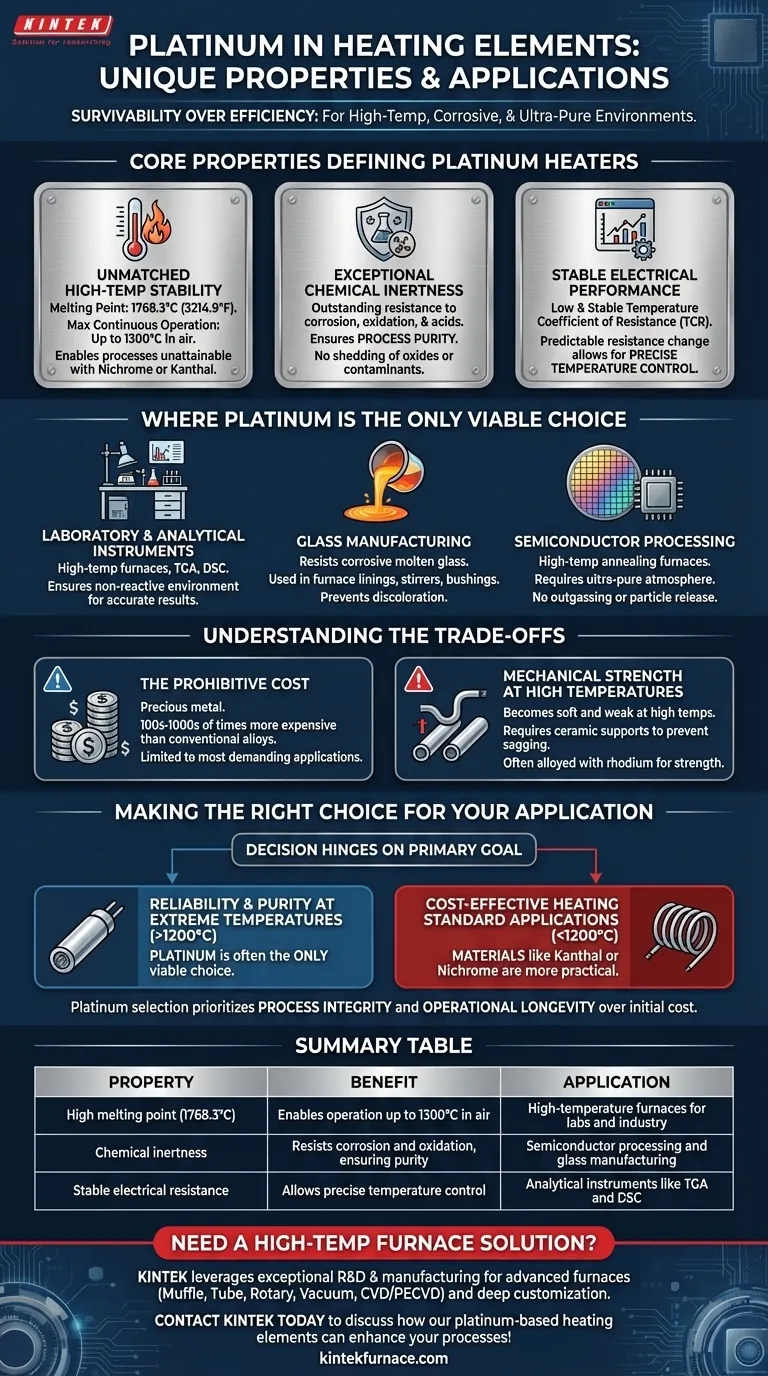

The Core Properties Defining Platinum Heaters

To understand why platinum is reserved for such specific duties, we must examine its three defining characteristics. Each one solves a problem that more common heating element materials cannot.

Unmatched High-Temperature Stability

Platinum possesses a very high melting point of 1768.3°C (3214.9°F). This fundamental property allows for a maximum continuous operating temperature of up to 1300°C in air.

This capability enables thermal processes that are simply unattainable with common alloys like Nichrome or Kanthal, which typically fail or degrade rapidly above 1200°C.

Exceptional Chemical Inertness

Platinum exhibits outstanding resistance to corrosion and oxidation, even at extreme temperatures. It does not readily react with air, water, or most acids.

This chemical stability is critical in applications where purity is paramount. A platinum heater will not shed oxides or other contaminants into the environment, which is essential for manufacturing sensitive materials like semiconductors, optical glass, or high-purity crystals.

Stable and Predictable Electrical Performance

Platinum has a low and stable temperature coefficient of resistance (TCR). This means its electrical resistance changes in a highly predictable and linear fashion as it heats up.

This predictability is invaluable for sophisticated equipment that requires precise temperature control. By accurately monitoring the element's resistance, control systems can maintain a set temperature with exceptional accuracy.

Where is Platinum the Only Viable Choice?

The combination of these properties makes platinum indispensable in a few high-stakes industries where failure or contamination carries a significant cost.

Laboratory and Analytical Instruments

High-temperature laboratory furnaces, thermogravimetric analyzers (TGA), and differential scanning calorimeters (DSC) rely on platinum heaters. The chemical inertness ensures that experimental results are not skewed by reactions between the heater and the sample being analyzed.

Glass Manufacturing

Molten glass is extremely corrosive to most metals. Platinum is one of the few materials that can contain and heat molten glass without being dissolved or introducing impurities that would discolor the final product. It is used for furnace linings, stirrers, and bushings.

Semiconductor Processing

In semiconductor fabrication, high-temperature annealing furnaces are used to modify the properties of silicon wafers. The process requires an ultra-pure atmosphere. Platinum heaters are used because they do not outgas or release particles that could create defects on the wafer.

Understanding the Trade-offs

Despite its superior performance, platinum is not a universal solution. Its selection comes with significant compromises that must be carefully considered.

The Prohibitive Cost

Platinum is a precious metal, and its price is the single greatest barrier to its widespread use. Its cost can be hundreds or even thousands of times higher than that of conventional heating element alloys.

This economic reality restricts its use to only the most demanding applications where no other material can provide the required performance and longevity.

Mechanical Strength at High Temperatures

While chemically robust, platinum becomes very soft and mechanically weak as it approaches its upper temperature limits. Platinum heating elements often require structural support from high-purity ceramic tubes or holders to prevent sagging and deformation over time.

For this reason, it is often alloyed with rhodium (another platinum-group metal) to increase its hot strength and creep resistance, albeit at an even higher cost.

Making the Right Choice for Your Application

The decision to use platinum must be justified by a clear, mission-critical need. The choice hinges on your primary goal.

- If your primary focus is reliability and purity at extreme temperatures (above 1200°C): Platinum is often the only viable choice, as its chemical inertness and stable performance are unmatched.

- If your primary focus is cost-effective heating for standard applications (below 1200°C): Materials like Kanthal (FeCrAl) or Nichrome (NiCr) are far more practical and economical solutions.

Ultimately, selecting platinum is an engineering decision to prioritize process integrity and operational longevity over initial equipment cost.

Summary Table:

| Property | Benefit | Application |

|---|---|---|

| High melting point (1768.3°C) | Enables operation up to 1300°C in air | High-temperature furnaces for labs and industry |

| Chemical inertness | Resists corrosion and oxidation, ensuring purity | Semiconductor processing and glass manufacturing |

| Stable electrical resistance | Allows precise temperature control | Analytical instruments like TGA and DSC |

Need a high-temperature furnace solution that ensures purity and reliability? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet the unique experimental requirements of diverse laboratories. Contact us today to discuss how our platinum-based heating elements can enhance your processes!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance