At its core, a vacuum carburizing furnace performs two primary, sequential functions. First, it executes low-pressure carburizing, a process that introduces carbon into the surface of steel parts within a vacuum to create a hard, wear-resistant outer layer. Second, it performs a controlled quenching (rapid cooling) cycle, typically using high-pressure gas or oil, to lock in that hardness and achieve the final desired material properties.

The fundamental advantage of a vacuum carburizing furnace is not just what it does, but how it does it. By creating a chemically pure and highly controlled environment, it eliminates the inconsistencies and part defects common in traditional methods, delivering superior metallurgical quality with exceptional repeatability.

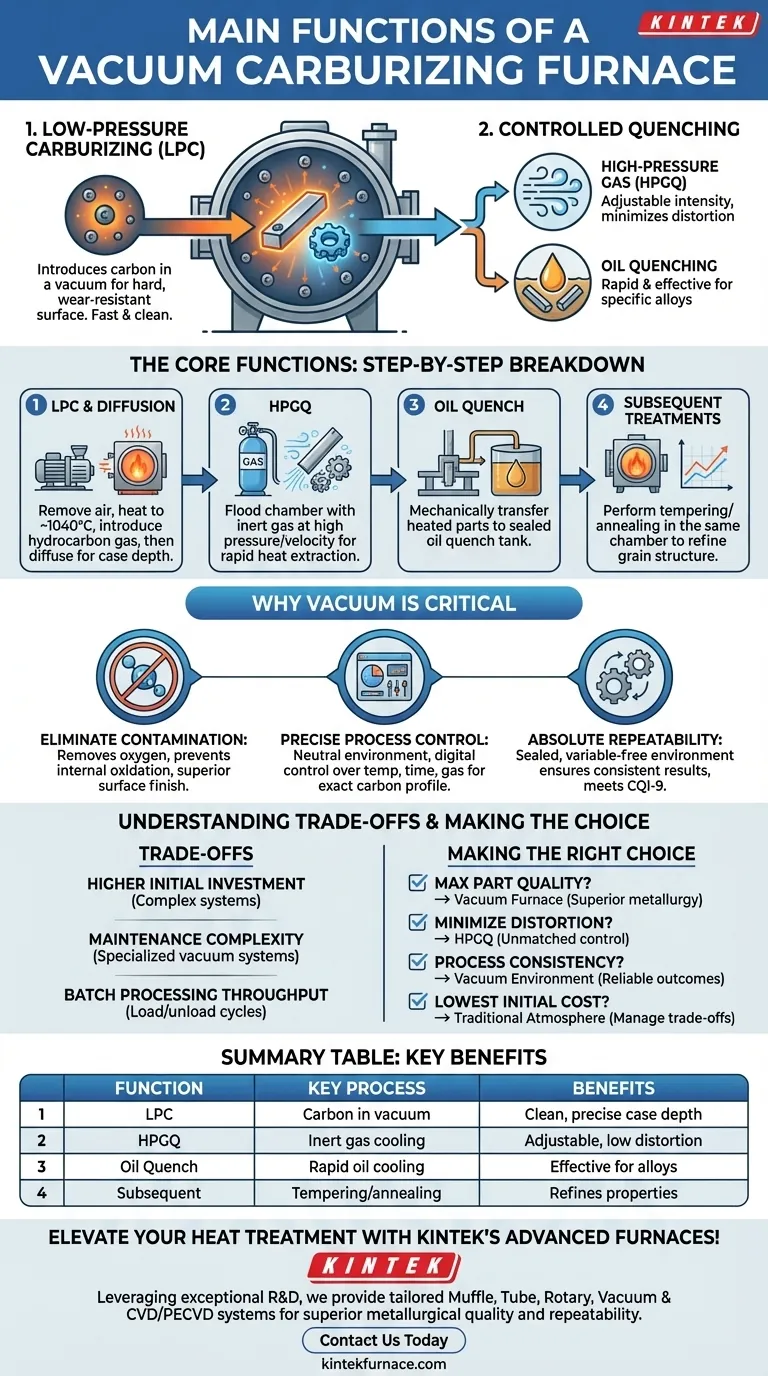

The Core Functions: A Step-by-Step Breakdown

To understand the furnace's capabilities, it's best to look at its functions as integrated stages of a complete heat treatment process.

Low-Pressure Carburizing (LPC)

The process begins by loading parts into the furnace's vacuum chamber. The system then removes all air and atmospheric gases.

Once the chamber is evacuated and heated to the precise carburizing temperature (often up to 1040°C), a pure hydrocarbon gas like propane or acetylene is introduced. In the vacuum, this gas efficiently provides the carbon that diffuses into the steel's surface.

After a set time, the gas supply is cut off, and a diffusion stage follows, allowing the absorbed carbon to penetrate deeper and create the desired case depth profile. This method is faster than traditional carburizing and produces a cleaner result.

High-Pressure Gas Quenching (HPGQ)

Following carburizing, the parts must be cooled rapidly to achieve hardness. The most advanced vacuum furnaces use high-pressure gas quenching.

Here, the heated chamber is flooded with an inert gas (like nitrogen or helium) at high pressure and velocity. This rapidly extracts heat from the parts.

The key benefit is that the quenching intensity is adjustable. By controlling the gas pressure and flow rate, engineers can minimize thermal shock and part distortion—a critical advantage for complex or thin-walled geometries.

Oil Quenching

For certain steel alloys or desired outcomes, a more aggressive quench is required. Many vacuum carburizing systems integrate an oil quench tank.

After the heating cycle, the parts are mechanically transferred from the hot zone into an sealed, adjoining chamber filled with quench oil. This provides a very rapid and effective hardening method while still benefiting from the clean heating environment of the vacuum.

Subsequent Heat Treatments

Modern, versatile vacuum furnaces can often perform subsequent heat treatment cycles in the same chamber. This can include processes like vacuum tempering or annealing to refine the material's final grain structure and mechanical properties, increasing operational efficiency.

Why Vacuum is the Critical Element

The use of a vacuum is not incidental; it is the enabling technology that provides the system's primary advantages over older atmosphere-based furnaces.

Eliminating Atmospheric Contamination

The most significant benefit of the vacuum is the removal of oxygen. This completely prevents internal oxidation at the surface of the part.

An oxidation-free surface results in superior fatigue strength and a higher quality finish, eliminating the need for post-treatment shot blasting or grinding in many cases.

Enabling Precise Process Control

A vacuum creates a perfectly neutral, stable environment. This allows for the precise, computer-controlled introduction of a single, pure carburizing gas.

There are no complex atmospheric gas chemistries to manage. This digital precision over temperature, time, and gas flow gives engineers unparalleled control over the final carbon profile and case depth.

Ensuring Absolute Repeatability

Because the process environment is sealed and digitally controlled, it eliminates the variables inherent in traditional furnaces (e.g., air leaks, changing atmospheric composition).

This results in exceptionally consistent and reproducible results from one batch to the next. This level of reliability is essential for meeting stringent quality standards like CQI-9 in the automotive and aerospace industries.

Understanding the Trade-offs

While powerful, vacuum carburizing technology comes with specific considerations. An objective analysis requires acknowledging them.

Higher Initial Investment

Vacuum carburizing furnaces are sophisticated systems incorporating advanced vacuum pumps, high-temperature-rated materials, and complex control systems. This results in a significantly higher initial capital cost compared to conventional atmosphere furnaces.

Maintenance Complexity

The vacuum pumps, seals, valves, and control instrumentation that enable the furnace's precision also require specialized maintenance. Maintaining the integrity of the vacuum system is critical for performance and demands well-trained technical staff.

Batch Processing Throughput

By its nature, the process of evacuating a chamber, processing a load, and bringing it back to atmospheric pressure is a batch operation. This may have different throughput implications than some continuous-belt atmosphere furnaces, a key consideration for very high-volume production planning.

Making the Right Choice for Your Application

Choosing the right heat treatment technology depends entirely on your operational priorities and quality requirements.

- If your primary focus is maximum part quality and performance: A vacuum furnace is the superior choice, as the clean, oxidation-free environment delivers measurably better metallurgical properties.

- If your primary focus is minimizing part distortion: The highly controllable nature of high-pressure gas quenching provides an unmatched ability to reduce scrap and rework on complex or sensitive parts.

- If your primary focus is process consistency and repeatability: The digitally controlled vacuum environment removes process variables, making it the ideal solution for meeting strict industry certifications and ensuring reliable outcomes.

- If your primary focus is the lowest initial equipment cost: A traditional atmosphere furnace may be more suitable, but you must be prepared to manage the associated trade-offs in process control, part quality, and potential for rework.

Ultimately, investing in vacuum carburizing is a decision to prioritize precision, quality, and repeatability in your heat treatment operations.

Summary Table:

| Function | Key Process | Benefits |

|---|---|---|

| Low-Pressure Carburizing | Introduces carbon into steel in a vacuum | Clean, oxidation-free surface; precise case depth control |

| High-Pressure Gas Quenching | Rapid cooling with inert gas | Adjustable quenching; minimizes distortion |

| Oil Quenching | Rapid cooling in oil for aggressive hardening | Effective for certain alloys; maintains clean heating |

| Subsequent Treatments | Vacuum tempering or annealing in same chamber | Refines properties; increases efficiency |

Elevate your heat treatment with KINTEK's advanced vacuum carburizing furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior metallurgical quality and repeatability. Contact us today to discuss how our furnaces can optimize your operations and deliver consistent, high-performance results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety