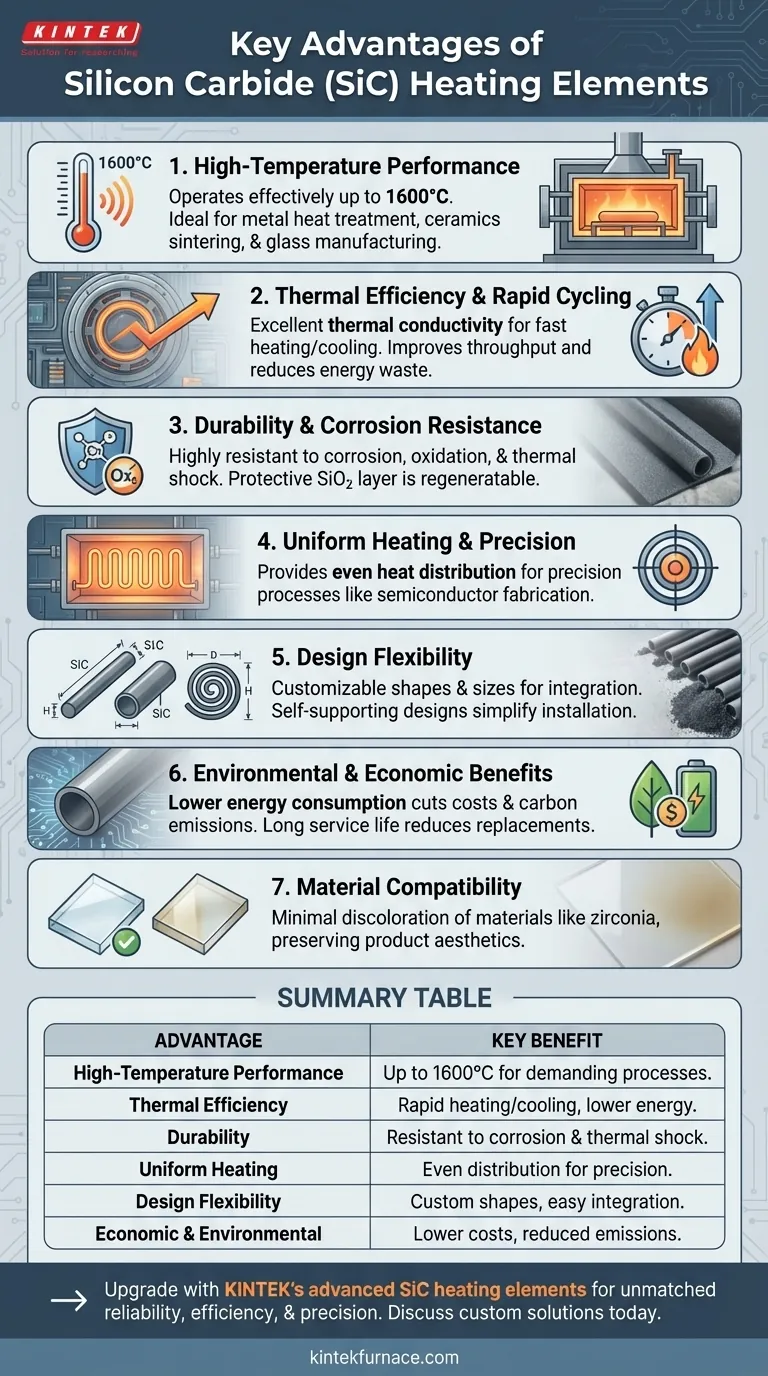

Silicon carbide (SiC) heating elements are widely favored in industrial applications due to their exceptional thermal properties, durability, and efficiency. They can withstand extreme temperatures up to 1600°C, offer high thermal conductivity for rapid heating and cooling, and provide uniform heat distribution, making them ideal for precision processes. Their self-supporting nature reduces the need for additional structural support, while their corrosion resistance ensures longevity even in harsh environments. Additionally, SiC elements are energy-efficient, lowering operational costs and carbon footprints, and can be customized in shape and size to fit diverse furnace designs, including controlled atmosphere furnaces.

Key Points Explained:

-

High-Temperature Performance

- SiC heating elements operate effectively at temperatures up to 1600°C, making them suitable for demanding industrial processes like metal heat treatment, ceramics sintering, and glass manufacturing.

- Their stability at extreme temperatures reduces the risk of deformation or failure, ensuring consistent performance over time.

-

Thermal Efficiency & Rapid Cycling

- Excellent thermal conductivity (14–18 kcal/M hr°C at 600°C) enables fast heating and cooling, improving throughput and reducing cycle times.

- This efficiency minimizes energy waste, aligning with sustainable practices and cost-saving goals.

-

Durability & Corrosion Resistance

- SiC is highly resistant to chemical corrosion, oxidation, and thermal shock, extending the lifespan of heating elements even in aggressive atmospheres.

- If the protective SiO₂ layer degrades, it can be regenerated by firing at 1450°C+ in an oxidizing atmosphere, restoring functionality.

-

Uniform Heating & Precision

- Ideal for laboratory and industrial furnaces, SiC elements provide even heat distribution, critical for processes like semiconductor fabrication or precision ceramics.

- Their reliability supports applications requiring strict temperature control, such as in controlled atmosphere furnaces.

-

Design Flexibility

- Customizable shapes (rods, tubes, spirals) and sizes allow integration into compact or specialized equipment, optimizing space and thermal output.

- Self-supporting designs eliminate the need for additional fixtures, simplifying installation.

-

Environmental & Economic Benefits

- Lower energy consumption reduces operational costs and carbon emissions, supporting greener manufacturing.

- Long service life decreases replacement frequency, further cutting costs and downtime.

-

Material Compatibility

- Unlike MoSi₂ heaters, SiC causes minimal discoloration of zirconia, preserving product aesthetics in high-value applications like dental ceramics or jewelry.

By combining these advantages, SiC heating elements address the core needs of industrial buyers: reliability, efficiency, and adaptability. Whether for high-temperature metallurgy or precision lab work, they offer a robust solution that balances performance with sustainability.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High-Temperature Performance | Operates up to 1600°C, ideal for metal heat treatment and ceramics sintering. |

| Thermal Efficiency | Rapid heating/cooling (14–18 kcal/M hr°C at 600°C), reducing energy waste. |

| Durability | Resists corrosion, oxidation, and thermal shock; SiO₂ layer regeneratable. |

| Uniform Heating | Even heat distribution for precision processes like semiconductor fabrication. |

| Design Flexibility | Customizable shapes (rods, tubes) and self-supporting for easy integration. |

| Economic & Environmental | Lowers energy costs, carbon emissions, and replacement frequency. |

Upgrade your industrial furnace with KINTEK's advanced SiC heating elements for unmatched durability, efficiency, and precision. Our in-house R&D and manufacturing ensure tailored solutions for your high-temperature needs, from metallurgy to lab-grade ceramics. Contact us today to discuss custom configurations or explore our range of controlled atmosphere furnaces.

Products You Might Be Looking For:

Shop high-performance SiC heating elements for electric furnaces Explore vacuum-compatible observation windows for process monitoring Discover precision vacuum valves for system control

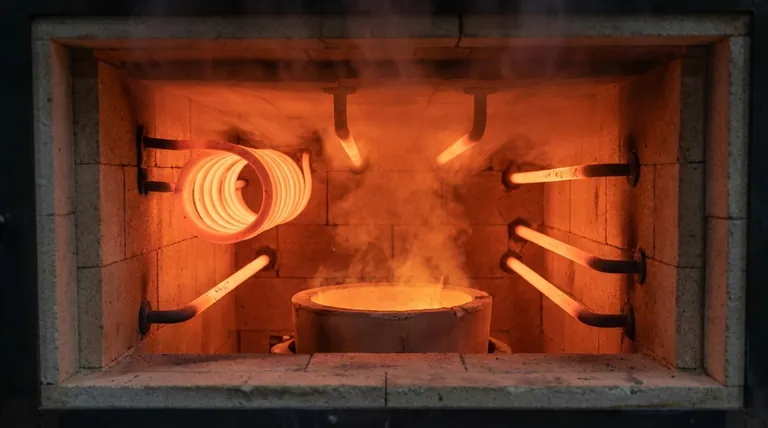

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan