At its core, vacuum heat treatment offers a superior method for strengthening metals by preventing the surface reactions that plague conventional heating processes. By removing atmospheric gases, the process prevents oxidation and decarburization, resulting in a bright, clean surface finish with minimal deformation and enhanced mechanical properties.

The fundamental advantage of vacuum heat treatment is not just preventing surface damage, but achieving an unparalleled level of process control. This transforms the treatment from a brute-force heating method into a precise metallurgical tool for creating higher-quality, more consistent, and better-performing components.

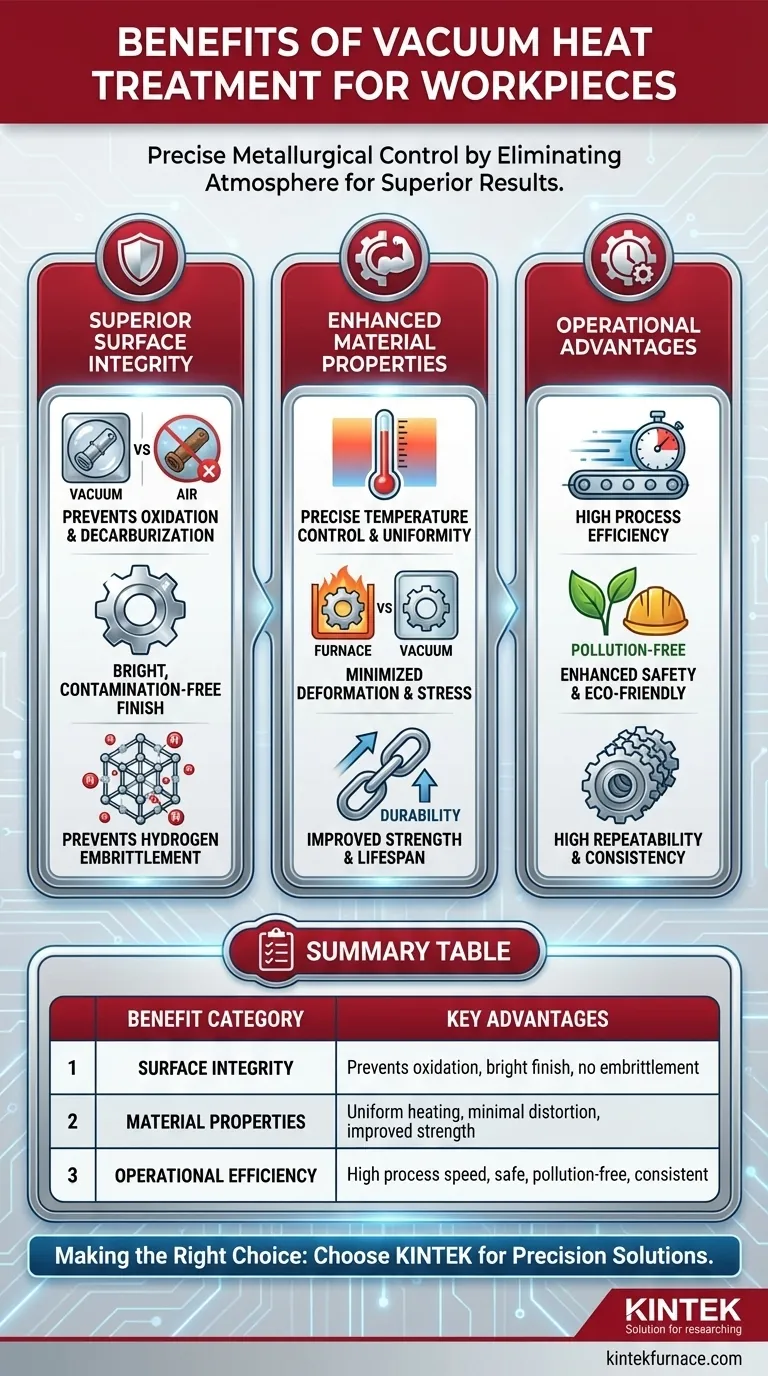

Achieving Superior Surface Integrity

The most immediate and obvious benefits of vacuum heat treatment relate to the quality and cleanliness of the finished workpiece surface. This is a direct result of removing the reactive gases present in a normal atmosphere.

Preventing Oxidation and Decarburization

In a conventional furnace, the oxygen in the air reacts with the hot metal surface, forming a layer of scale (oxidation). The carbon within the steel can also react and diffuse out of the surface (decarburization), weakening the material.

A vacuum environment virtually eliminates these reactive gases. This preserves the original surface chemistry and integrity of the component, ensuring its metallurgical properties are not compromised.

Creating a Bright, Contamination-Free Finish

Because oxidation is prevented, parts emerge from the vacuum furnace with a bright, clean, and often shiny surface. This high-quality finish frequently eliminates the need for post-treatment cleaning, grinding, or machining to remove scale.

Furthermore, the high heat and vacuum can pull impurities, oils, and residual phosphorus from the surface, a process known as degassing. This results in a purer, cleaner final product.

Preventing Hydrogen Embrittlement

Certain processes and materials are susceptible to hydrogen embrittlement, where hydrogen atoms infiltrate the metal's grain structure, making it brittle. Vacuum processing effectively eliminates the source of hydrogen, preventing this common failure mode.

Enhancing Material Properties and Performance

Beyond surface quality, the controlled environment of a vacuum furnace allows for precise manipulation of a material's internal structure, leading to significant performance gains.

Precise Temperature Control and Uniformity

Heating in a vacuum occurs primarily through radiation, which is exceptionally uniform. This ensures the entire workpiece, including complex geometries, reaches the target temperature at the same time, avoiding hot or cold spots.

This high degree of temperature control and uniformity is critical for achieving consistent and predictable metallurgical transformations throughout the part.

Minimizing Deformation and Thermal Stress

Uniform heating, combined with precisely controlled cooling (quenching) rates, dramatically reduces thermal stress within the component. This results in minimal distortion, warping, and dimensional change.

For high-precision parts like tools, dies, and aerospace components, this benefit is paramount, as it reduces scrap rates and the need for costly final adjustments.

Improving Mechanical Properties and Lifespan

The combination of a pristine surface, no decarburization, and a uniform, finely-tuned microstructure results in superior mechanical properties. Treated components exhibit improved strength, durability, and fatigue resistance.

This directly translates to a longer service life for tools, molds, and critical engineering parts, delivering significant value over time.

Understanding the Operational Advantages

Vacuum heat treatment also offers compelling benefits for the manufacturing operation itself, impacting efficiency, safety, and cost.

High Process Efficiency

Modern vacuum furnaces have high thermal efficiency, allowing for rapid heating and cooling cycles. This can shorten overall process times compared to some conventional atmosphere furnace methods.

Enhanced Safety and Environmental Friendliness

Vacuum furnaces are inherently safer, as they eliminate the need to handle, store, and manage large volumes of potentially flammable, explosive, or toxic gases (like hydrogen or ammonia) used in atmosphere-controlled furnaces.

The process is also pollution-free, producing no harmful emissions or byproducts, which simplifies regulatory compliance and reduces environmental impact.

High Repeatability and Consistency

The process is highly automated and computer-controlled. Once a treatment "recipe" is established, it can be executed with exceptional repeatability and consistency from batch to batch. This leads to a higher pass rate and more reliable production outcomes.

Making the Right Choice for Your Application

Choosing vacuum heat treatment depends on the specific requirements of your component and your operational priorities.

- If your primary focus is high-precision components: The minimal distortion and bright finish eliminate costly post-processing, making it the ideal choice for tools, dies, and aerospace parts.

- If your primary focus is material integrity: For reactive alloys or applications where surface chemistry is critical, vacuum processing is the only way to guarantee no oxidation or decarburization.

- If your primary focus is performance and lifespan: The enhanced mechanical properties and fatigue resistance delivered by vacuum treatment will maximize the service life of critical components.

- If your primary focus is operational safety and sustainability: Vacuum heat treatment provides a cleaner, safer, and more environmentally friendly alternative to traditional atmosphere furnaces.

Ultimately, vacuum heat treatment offers a superior level of control, transforming it from a simple heating process into a precision engineering tool.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Surface Integrity | Prevents oxidation and decarburization, bright finish, eliminates hydrogen embrittlement |

| Material Properties | Precise temperature control, uniform heating, minimal deformation, improved strength and fatigue resistance |

| Operational Efficiency | High process efficiency, enhanced safety, pollution-free, high repeatability |

| Application Suitability | Ideal for high-precision, reactive alloys, performance-critical, and safety-focused uses |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision-engineered products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering enhanced efficiency, safety, and performance. Contact us today to discuss how our tailored solutions can transform your heat treatment processes and achieve superior results for your workpieces!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance