When choosing a joining process, the primary difference between vacuum brazing and welding is not merely technique, but a fundamental philosophy of how to treat the base materials. While welding fuses parts by melting them together, vacuum brazing joins them with a filler metal at a lower temperature, preserving the integrity of the components. This results in superior dimensional stability, the ability to join dissimilar materials, and pristine, clean joints without distortion.

The decision between vacuum brazing and welding is not about which is "better," but which process best preserves the essential properties of your components. Welding fuses parts by altering their structure, while vacuum brazing joins them without compromise, maintaining their original strength and dimensions.

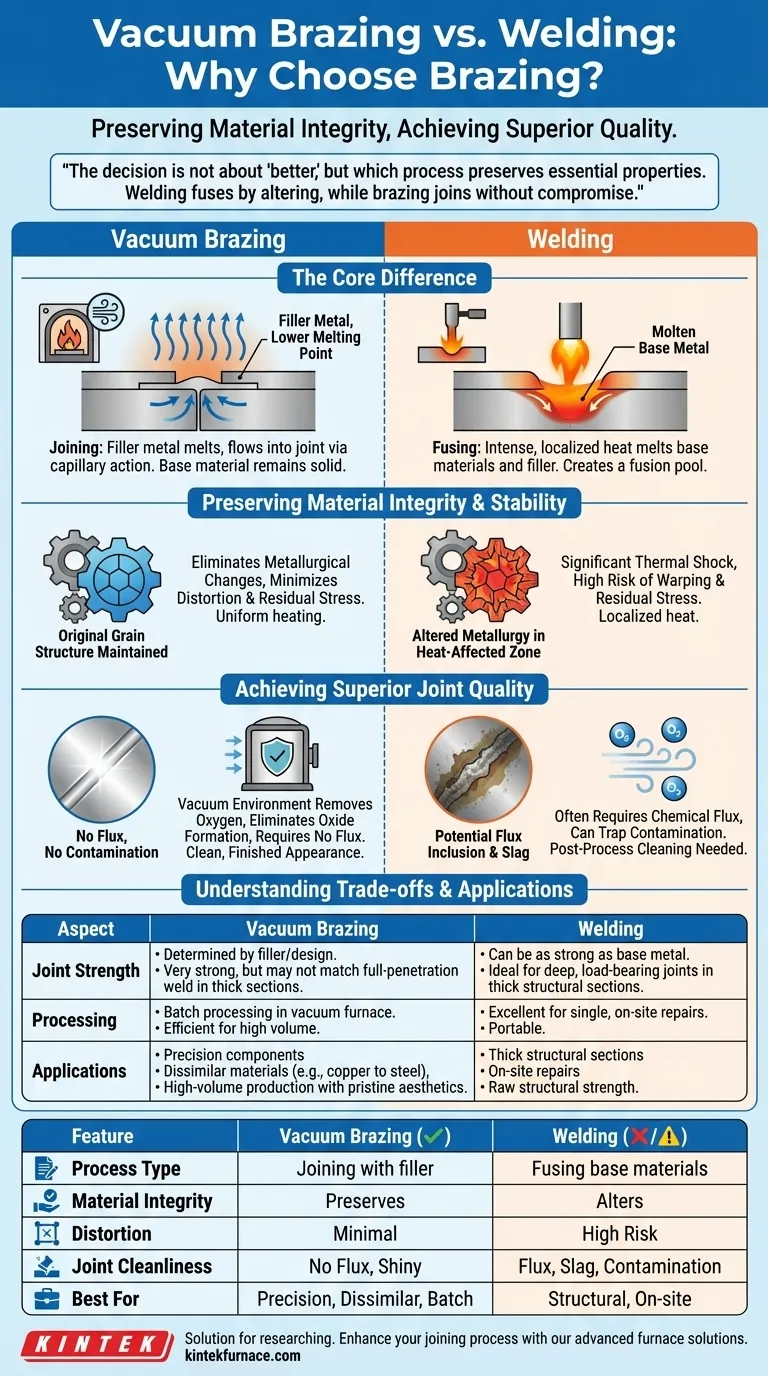

The Core Difference: Joining vs. Fusing

At the heart of this comparison is how each process achieves a bond. Understanding this distinction is key to selecting the right method for your application.

How Vacuum Brazing Works

Vacuum brazing is a process where a filler metal, with a melting point lower than the base components, is used to create a joint. Parts are assembled, the filler metal is applied, and the entire assembly is heated uniformly within a vacuum furnace. The vacuum prevents oxidation, and the filler metal melts and flows into the joint via capillary action, creating a strong, clean bond upon cooling.

How Welding Works

Welding, in contrast, uses intense, localized heat to melt the edges of the parent materials themselves, often along with a filler material. This molten pool of metal from the components solidifies to form the joint. This process fundamentally alters the metallurgy of the base materials in the heat-affected zone.

Preserving Material Integrity and Stability

The greatest advantage of vacuum brazing lies in its gentle, controlled nature, which protects the parts being joined.

Eliminating Metallurgical Changes

Because vacuum brazing occurs below the melting point of the base materials, it does not alter their inherent properties. The grain structure, hardness, and strength of the parent components remain unchanged, which is critical for precision-engineered or heat-treated parts.

Minimizing Distortion and Residual Stress

The slow, uniform heating and cooling inside a furnace minimizes thermal shock and residual stress. This prevents the warping and distortion commonly associated with the intense, localized heat of welding, ensuring high dimensional accuracy in the final assembly.

Achieving Superior Joint Quality

The environment in which the joint is made has a profound impact on its final quality and appearance.

The Role of the Vacuum Environment

The vacuum acts as the ultimate protective shield. By removing oxygen and other atmospheric contaminants, it prevents the formation of oxides on the metal surfaces. This ensures the filler metal can bond cleanly and effectively with the parent materials.

No Flux, No Contamination

Traditional brazing and welding often require a chemical flux to clean the surfaces and prevent oxidation. This flux can become trapped in the joint, leading to corrosion and potential failure points. Vacuum brazing requires no flux, eliminating this risk entirely and removing the need for post-process cleaning.

A Clean, Finished Appearance

Parts emerge from a vacuum furnace with bright, shiny, and clean joints. There is no slag, spatter, or discoloration to remove, significantly reducing post-processing labor and costs.

Understanding the Trade-offs

No process is universally superior. Acknowledging the trade-offs is essential for making an informed decision.

Joint Strength and Design

A properly executed weld can create a joint that is as strong as the base metal itself. A brazed joint's strength is determined by the filler metal and the design of the joint (specifically, the gap tolerance and surface area). While very strong, it may not match the ultimate strength of a full-penetration weld in thick, structural applications.

Equipment and Batch Processing

Vacuum furnaces represent a significant capital investment and are best suited for batch processing. This is highly efficient for high-volume production runs but is not practical for single, on-site repairs where a portable welder excels.

Combining Processes

A key efficiency of vacuum brazing is the ability to combine multiple thermal processes. It's possible to perform brazing, heat treating, and age hardening all in a single, automated furnace cycle, saving immense time and energy in a production environment.

Making the Right Choice for Your Application

Select your process based on the non-negotiable requirements of your project.

- If your primary focus is precision and delicate components: Vacuum brazing is the definitive choice to maintain dimensional stability and prevent material damage.

- If your primary focus is joining dissimilar materials (like copper to steel, or metal to ceramic): Vacuum brazing is one of the most reliable and effective methods available.

- If your primary focus is raw structural strength on thick sections: Welding is often the more direct and cost-effective solution for creating deep, load-bearing joints.

- If your primary focus is high-volume production with pristine aesthetics: The efficiency and cleanliness of vacuum brazing make it ideal for manufacturing repeatable, finished-quality parts.

By understanding these core principles, you can confidently select the joining method that protects the integrity and intent of your design.

Summary Table:

| Aspect | Vacuum Brazing | Welding |

|---|---|---|

| Process Type | Joining with filler metal below base melting point | Fusing by melting base materials |

| Material Integrity | Preserves grain structure and properties | Alters metallurgy in heat-affected zone |

| Distortion | Minimal due to uniform heating | High risk of warping and residual stress |

| Joint Cleanliness | No flux, oxidation-free, shiny finish | May require flux, leading to slag and contamination |

| Suitable Applications | Precision components, dissimilar materials, high-volume production | Thick structural sections, on-site repairs |

Ready to enhance your joining process with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your lab. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're working with delicate components or dissimilar materials, our vacuum brazing solutions ensure superior joint quality and efficiency. Contact us today to discuss how we can support your projects and deliver optimal results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment