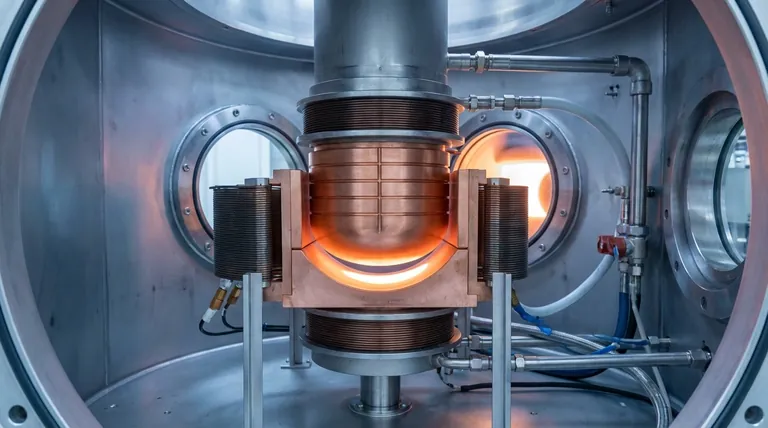

The curved bottom design in Induction Skull Melting (ISM) functions by optimizing the direction of electromagnetic forces to enhance levitation. By manipulating the electromagnetic field to act along the normal direction of the curved surface, this geometry significantly increases the lifting force exerted on the bottom of the charge. This enhanced lift creates a critical separation known as "soft contact," which isolates the molten metal from the cold crucible wall to improve thermal efficiency.

Core Insight: A curved bottom geometry generates vertical electromagnetic lift that physically detaches the molten charge from the crucible floor. This "soft contact" drastically reduces heat conduction losses, resulting in a more uniform chemical composition and superior metal purity.

The Mechanism of Enhanced Levitation

Directed Electromagnetic Forces

In a standard flat-bottom crucible, electromagnetic forces may not effectively lift the center of the charge.

A curved bottom changes this dynamic. The design induces electromagnetic forces that act along the normal direction of the curved surface. This geometry naturally directs force vectors upward and inward, concentrating the lifting effect at the bottom of the charge where it is needed most.

Achieving "Soft Contact"

The primary mechanical goal of this design is to create a physical gap between the charge and the water-cooled copper crucible.

This phenomenon is technically referred to as soft contact. By utilizing the enhanced lifting force, an air gap is formed. This ensures the molten metal is supported primarily by the magnetic field rather than physical contact with the crucible floor.

Thermal and Chemical Benefits

Reducing Heat Conduction Losses

The most immediate impact of soft contact is thermal insulation.

Because the molten charge is not pressing directly against the cold crucible, heat conduction losses are significantly reduced. The air gap acts as an insulator, allowing the metal to retain the heat generated by induction rather than losing it to the cooling water system.

Improving Uniformity and Purity

Thermal efficiency directly translates to better melting kinetics.

With reduced heat loss, the melt maintains a higher and more consistent temperature profile. This promotes better fluidity and stirring, leading to a more uniform chemical composition throughout the ingot. Furthermore, minimizing contact with the crucible prevents contamination, ensuring higher metal purity in the final solidified product.

Complementary Efficiency Factors

While the curved bottom optimizes lift and thermal isolation, other design parameters control how much energy actually reaches the metal.

Optimizing Slit Density

To further improve kinetics, the number of sections (slits) in the crucible plays a vital role.

Increasing the section number reduces eddy current losses within the copper segments. This lowers the magnetic shielding effect, allowing more electromagnetic potential energy to be directed into the metal charge rather than being wasted as heat in the crucible walls.

Wall Thickness and Mass

The physical mass of the crucible also affects efficiency.

A thin-wall structure with wide slits reduces the overall mass of the crucible. This minimizes ineffective electromagnetic losses associated with the crucible's volume. Wide slits help converge the magnetic flux, increasing field strength and boosting energy utilization efficiency—potentially raising it from ~27% to over 38%.

Understanding the Trade-offs

Manufacturing Complexity

While aerodynamically and electromagnetically superior, curved bottoms are more complex to manufacture.

Machining the copper segments to precise curves requires tighter tolerances than standard flat-bottom designs. This can increase the initial fabrication cost and lead time for the equipment.

Structural Integrity vs. Efficiency

Pushing for maximum efficiency involves balancing structural strength with electromagnetic permeability.

As noted in supplementary findings, thinner walls and wider slits improve energy transfer. However, this must be balanced against the structural integrity required to contain the molten mass and withstand the thermal gradients inherent in the ISM process.

Making the Right Choice for Your Goal

To maximize the performance of your Induction Skull Melting process, you must align the crucible geometry with your specific processing targets.

- If your primary focus is Metal Purity and Homogeneity: Prioritize a curved bottom design to maximize electromagnetic lift and create the "soft contact" necessary to minimize contamination and thermal loss.

- If your primary focus is Energy Consumption: Focus on increasing the number of sections and widening the slits, as this directly reduces magnetic shielding and improves the energy utilization efficiency of the coil.

By combining a curved bottom for thermal isolation with a high-segment-count structure for energy transfer, you achieve the optimal balance of purity and kinetic efficiency.

Summary Table:

| Feature | Benefit of Curved Bottom Design |

|---|---|

| Electromagnetic Force | Directs lift along the normal vector to physically detach the charge |

| Contact Type | Creates 'Soft Contact' (air gap) between molten metal and crucible |

| Thermal Efficiency | Significantly reduces heat conduction losses to the cooling system |

| Metal Quality | Enhances chemical uniformity and prevents crucible contamination |

| Process Yield | Higher energy utilization for superior melting of reactive metals |

Maximize Your Melting Purity with KINTEK Expertise

Is your lab or production facility struggling with thermal losses or contamination in reactive metal melting? KINTEK’s advanced engineering team specializes in high-performance heating solutions tailored to your specific research goals.

Backed by expert R&D and world-class manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized induction melting components designed for precision and durability. Our technical specialists can help you select the ideal crucible geometry and slit configuration to optimize your energy efficiency and material purity.

Ready to elevate your material processing?

Contact KINTEK Today to Consult with an Expert

References

- Chaojun Zhang, Jianfei Sun. Optimizing energy efficiency in induction skull melting process: investigating the crucial impact of melting system structure. DOI: 10.1038/s41598-024-56966-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Induction Melting Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of an Induction Cold Crucible Furnace (ICCF) for Nb-MASC? Achieve Ultimate High-Purity Melting

- What technologies are used to achieve fully automatic operation in gold induction furnaces? Boost Efficiency and Consistency

- How does the selection of an industrial EAF influence carbon steel purity? Optimize Your Melt Quality

- Why is a double-layer water-cooled stainless steel chamber used in equipment for preparing ultrafine magnesium powder via the evaporation-condensation method?

- How does IGBT technology increase melting capacity and productivity? Unlock Faster Melts and Higher Output

- What are the advantages of using a vacuum casting furnace? Achieve Purity and Precision in Metal Processing

- Why is it necessary to perform multiple flips and repeat melting of metal buttons? Achieving Sample Homogeneity

- How does induction heating work in a vacuum environment? Achieve High-Purity, Contamination-Free Heat Treatment