The primary advantage of vacuum brazing is its ability to produce exceptionally clean, strong, and stress-free joints. This is achieved by performing the joining process inside a high-vacuum furnace, which removes atmospheric gases like oxygen and nitrogen that would otherwise contaminate the metals. The result is a superior metallurgical bond with properties that are often impossible to achieve with other joining methods.

The true value of vacuum brazing extends beyond just a clean joint; it lies in its unparalleled process control. By eliminating atmospheric variables and precisely managing temperature, it preserves the structural and metallurgical integrity of the base materials, making it the definitive choice for high-performance components where failure is not an option.

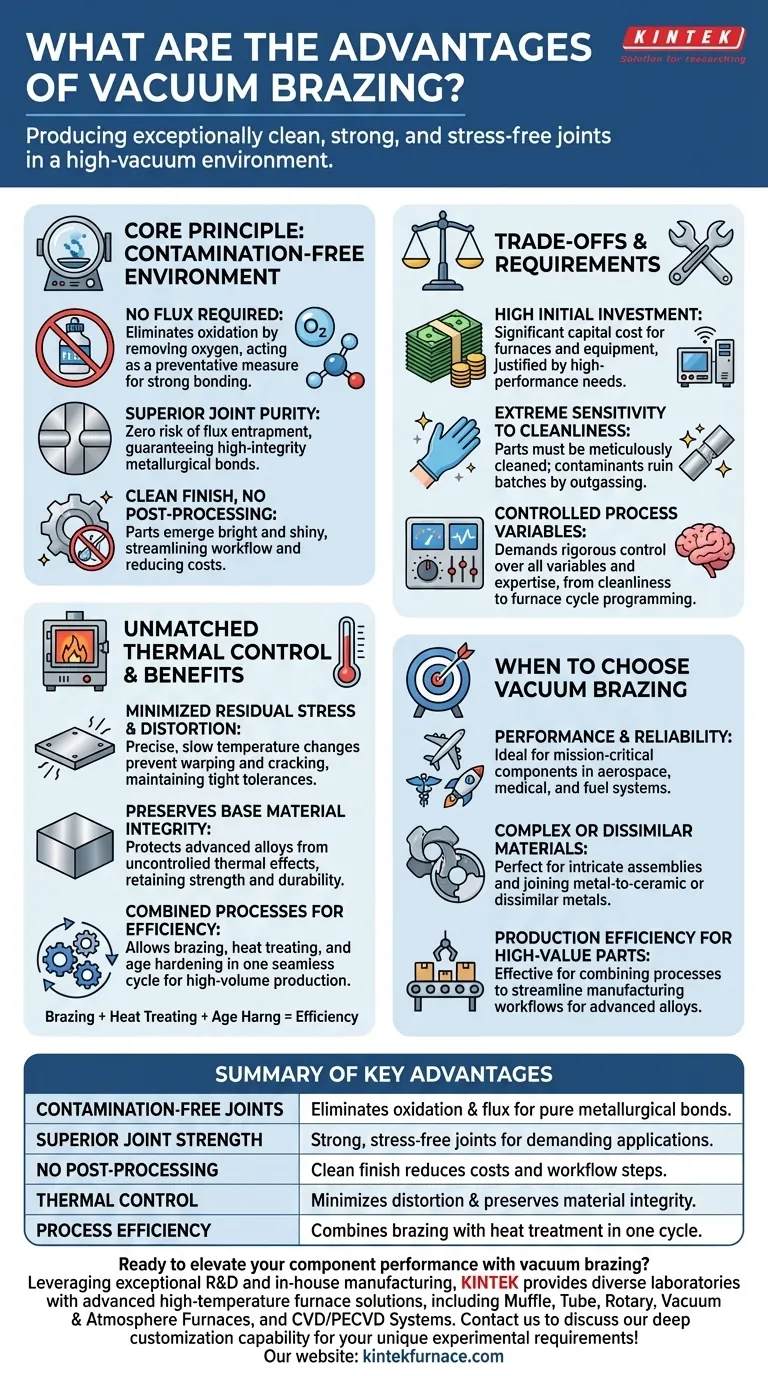

The Core Principle: A Contamination-Free Environment

Vacuum brazing's most defining characteristic is the environment in which it occurs. By removing the atmosphere, the process fundamentally changes how the metals interact, leading to several key benefits.

Eliminating Oxidation Without Flux

In a conventional brazing operation, a chemical agent called flux is required to clean the surfaces and prevent oxides from forming during heating. A vacuum furnace makes this unnecessary.

By removing the oxygen, the vacuum itself acts as the preventative measure against oxidation. This ensures the filler metal can properly wet the surfaces of the parent materials for a strong bond.

Achieving Superior Joint Purity

Because no flux is used, there is zero risk of flux entrapment. Trapped flux can become a point of corrosion or a structural weak point within the finished joint.

The absence of flux guarantees a pure, high-integrity metallurgical bond between the filler and the base metals, a critical factor for components in demanding environments like hydraulic or fuel systems.

A Clean Finish with No Post-Processing

A direct result of preventing oxidation is that the finished parts emerge from the furnace bright, shiny, and clean.

This often eliminates the need for costly and time-consuming post-braze cleaning operations, streamlining the entire manufacturing workflow and reducing overall costs.

Unmatched Thermal Control and Its Benefits

A vacuum furnace offers a highly controlled and uniform heating environment. This precision provides significant advantages for the mechanical properties of the final assembly.

Minimizing Residual Stress and Distortion

The heating and cooling rates within a vacuum furnace can be precisely programmed. This allows for slow, uniform temperature changes across the entire assembly.

This gentle thermal cycling minimizes the internal stresses that cause warping, distortion, or cracking, ensuring the final part maintains its designed shape and tight tolerances.

Preserving Base Material Integrity

Many high-performance alloys, such as those used in gas turbines and aerospace, are highly sensitive to thermal effects. Uncontrolled heating can alter their carefully engineered metallurgical properties.

Vacuum brazing protects the integrity of these advanced materials, ensuring they retain their strength and durability after the joining process is complete.

Combining Processes for Maximum Efficiency

A vacuum furnace is not just a brazing tool; it's a thermal processing unit. This allows for multiple treatments to be performed in a single cycle.

Processes like brazing, heat treating, and age hardening can be combined into one seamless operation. This consolidation saves significant time, energy, and handling, making it highly efficient for high-volume production.

Understanding the Trade-offs and Requirements

While the advantages are significant, vacuum brazing is a highly technical process with specific requirements that make it unsuitable for every application.

High Initial Investment

Vacuum furnaces and their supporting equipment represent a significant capital investment. This process is typically employed for high-value components where the cost is justified by the required performance and reliability.

Extreme Sensitivity to Cleanliness

The process's greatest strength is also a strict requirement. The parts to be brazed must be meticulously cleaned before entering the furnace. Any oils, grease, or other contaminants can outgas in the vacuum, ruining the entire batch.

Controlled Process Variables

Success in vacuum brazing depends on rigorous control over every variable, from the cleanliness of the assembly rooms and loading tools to the precise programming of the furnace cycle. It is a process that demands expertise and discipline.

When to Choose Vacuum Brazing

Your choice to use vacuum brazing should be driven by the specific demands of your component and material.

- If your primary focus is performance and reliability: Vacuum brazing is the ideal choice for mission-critical components in aerospace, medical, or fuel systems where joint failure is catastrophic.

- If your primary focus is joining complex or dissimilar materials: Choose vacuum brazing when you need to join intricate assemblies, dissimilar metals, or metal-to-ceramic components that cannot be welded.

- If your primary focus is production efficiency for high-value parts: Vacuum brazing is highly effective when you can combine brazing with required heat treatment cycles, streamlining the manufacturing workflow for advanced alloys.

Ultimately, selecting vacuum brazing is a decision to prioritize metallurgical integrity and process control above all else.

Summary Table:

| Advantage | Description |

|---|---|

| Contamination-Free Joints | Eliminates oxidation and flux, ensuring pure metallurgical bonds. |

| Superior Joint Strength | Produces strong, stress-free joints ideal for demanding applications. |

| No Post-Processing | Parts emerge clean and shiny, reducing costs and workflow steps. |

| Thermal Control | Minimizes distortion and preserves base material integrity. |

| Process Efficiency | Allows combining brazing with heat treatment in one cycle. |

Ready to elevate your component performance with vacuum brazing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your reliability and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions