At its core, Metal-Organic Chemical Vapor Deposition (MOCVD) is the leading industrial process for manufacturing high-performance compound semiconductor devices. Its primary advantages are the ability to deposit atomically precise, highly uniform layers of material over large areas. This combination of fine control and scalability makes it indispensable for producing complex electronic and optoelectronic components like LEDs, laser diodes, and high-power transistors.

MOCVD's true value lies in its unparalleled control. It allows engineers to construct complex semiconductor heterostructures layer by atomic layer, achieving a level of precision and uniformity that is critical for the performance and mass production of modern electronic devices.

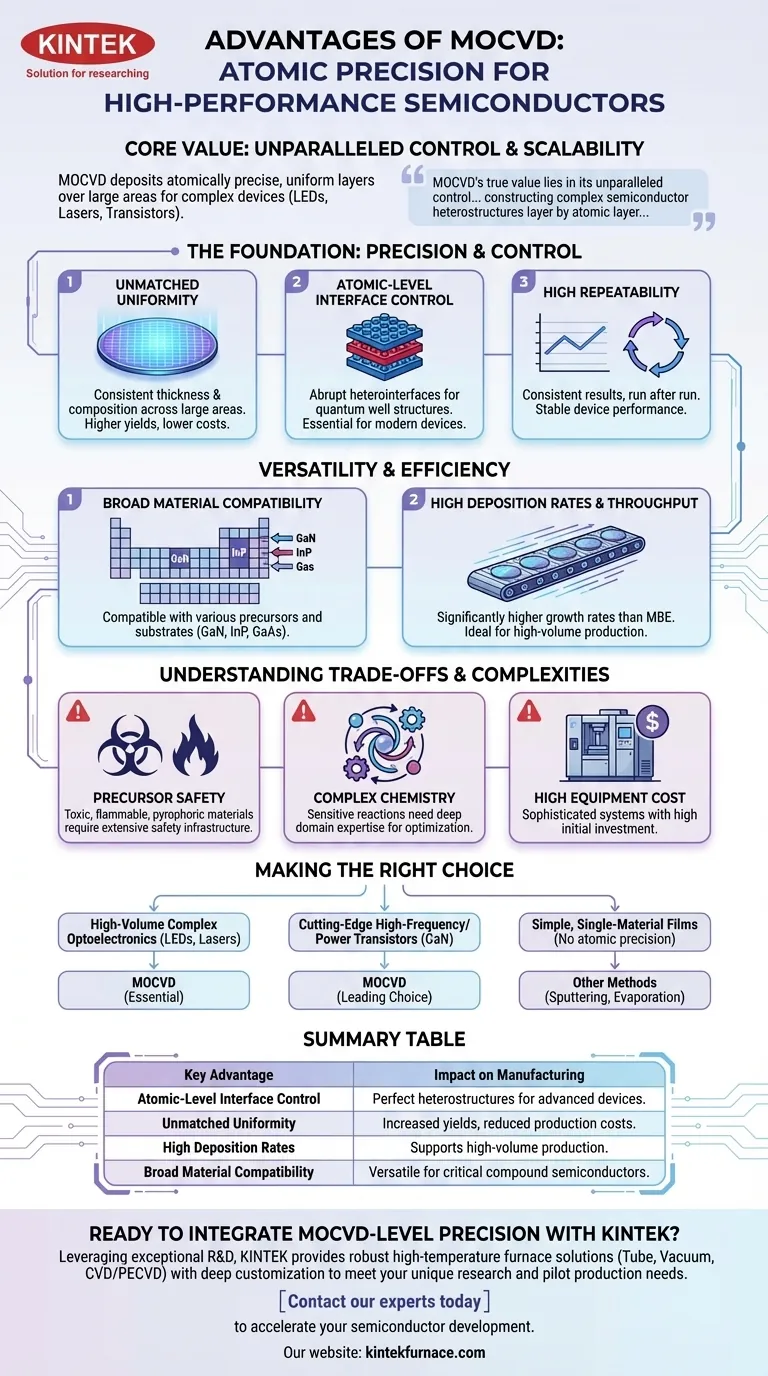

The Foundation: Precision and Control

The main advantages of MOCVD stem from its ability to precisely control the growth of thin films at the atomic level. This control is the reason it has become a cornerstone of the semiconductor industry.

Unmatched Uniformity Across Large Areas

MOCVD excels at depositing films with exceptionally uniform thickness and chemical composition. This consistency can be maintained across an entire large-area wafer.

This uniformity is not just a technical curiosity; it directly translates to higher manufacturing yields. When every device on a wafer performs identically, more chips are viable for sale, significantly reducing production costs.

Atomic-Level Interface Control

The technique allows for the creation of abrupt heterointerfaces, which are perfectly sharp transitions between different semiconductor materials.

Think of this as building with different types of LEGO bricks, where each layer clicks perfectly into place without any mixing. This capability is essential for fabricating advanced quantum well structures, which are the functional heart of modern laser diodes and high-efficiency LEDs.

High Degree of Repeatability

Once a process is dialed in, MOCVD delivers highly consistent results from one production run to the next. The precise digital control over gas flows and reaction conditions ensures that device characteristics remain stable over time.

This repeatability is critical for commercial manufacturing, where customers expect consistent performance from every component they purchase.

Versatility and Production Efficiency

Beyond precision, MOCVD is a highly practical and efficient manufacturing technology, adaptable to a wide range of needs.

Broad Material and Substrate Compatibility

MOCVD is not limited to a single material system. It is a highly versatile technique compatible with a vast library of precursor gases and substrates.

This allows it to be used for growing many of the most important compound semiconductors, including Gallium Nitride (GaN), Indium Phosphide (InP), and Gallium Arsenide (GaAs), which are the basis for RF electronics, fiber optics, and solid-state lighting.

High Deposition Rates for Throughput

Compared to other atomic-level deposition techniques like Molecular Beam Epitaxy (MBE), MOCVD generally offers significantly higher growth rates.

This efficiency means more wafers can be processed in less time, increasing factory throughput and further lowering the cost per device. This advantage is a key reason MOCVD dominates high-volume production for applications like general lighting.

Understanding the Trade-offs and Complexities

While powerful, MOCVD is not without its challenges. Its advantages come with significant operational complexities and costs.

Precursor Handling and Safety

The "metal-organic" precursors used in MOCVD are often highly toxic, flammable, and pyrophoric (igniting spontaneously in air). Handling these materials requires extensive safety infrastructure and rigorous protocols, adding to operational overhead.

Complex Chemistry and Optimization

The chemical reactions inside an MOCVD reactor are incredibly complex and sensitive to small changes in temperature, pressure, and gas flow dynamics. Optimizing a new process can be a time-consuming and expensive endeavor requiring deep domain expertise.

High Initial Equipment Cost

MOCVD reactors are sophisticated and expensive systems. The high capital investment required can be a barrier to entry, especially when compared to simpler thin-film deposition methods like sputtering or evaporation.

Making the Right Choice for Your Application

Selecting a deposition technology depends entirely on your final goal. MOCVD is a specialized tool that excels in specific domains.

- If your primary focus is high-volume production of complex optoelectronics (like LEDs or lasers): MOCVD's combination of uniformity, throughput, and atomic-level control is virtually essential.

- If your primary focus is fabricating cutting-edge high-frequency or high-power transistors: The ability to create perfect heterostructures makes MOCVD a leading choice for materials like GaN.

- If your primary focus is depositing simple, single-material films where atomic precision is not critical: Other methods like sputtering or thermal evaporation are often more cost-effective and simpler to operate.

Ultimately, MOCVD is the technology of choice when the performance of your device is directly tied to the perfection of its atomic structure.

Summary Table:

| Key Advantage | Impact on Semiconductor Manufacturing |

|---|---|

| Atomic-Level Interface Control | Enables creation of perfect heterostructures for advanced laser diodes and quantum well devices |

| Unmatched Uniformity Across Large Areas | Increases manufacturing yield and reduces production costs for consistent device performance |

| High Deposition Rates & Throughput | Supports high-volume production for applications like solid-state lighting and RF electronics |

| Broad Material Compatibility | Versatile for growing GaN, InP, GaAs and other critical compound semiconductors |

Ready to Integrate MOCVD-Level Precision into Your Lab?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides semiconductor and advanced materials laboratories with robust high-temperature furnace solutions. Our product line, including advanced Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique research and pilot production requirements.

Contact our experts today to discuss how our customized thermal solutions can accelerate your semiconductor development.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials