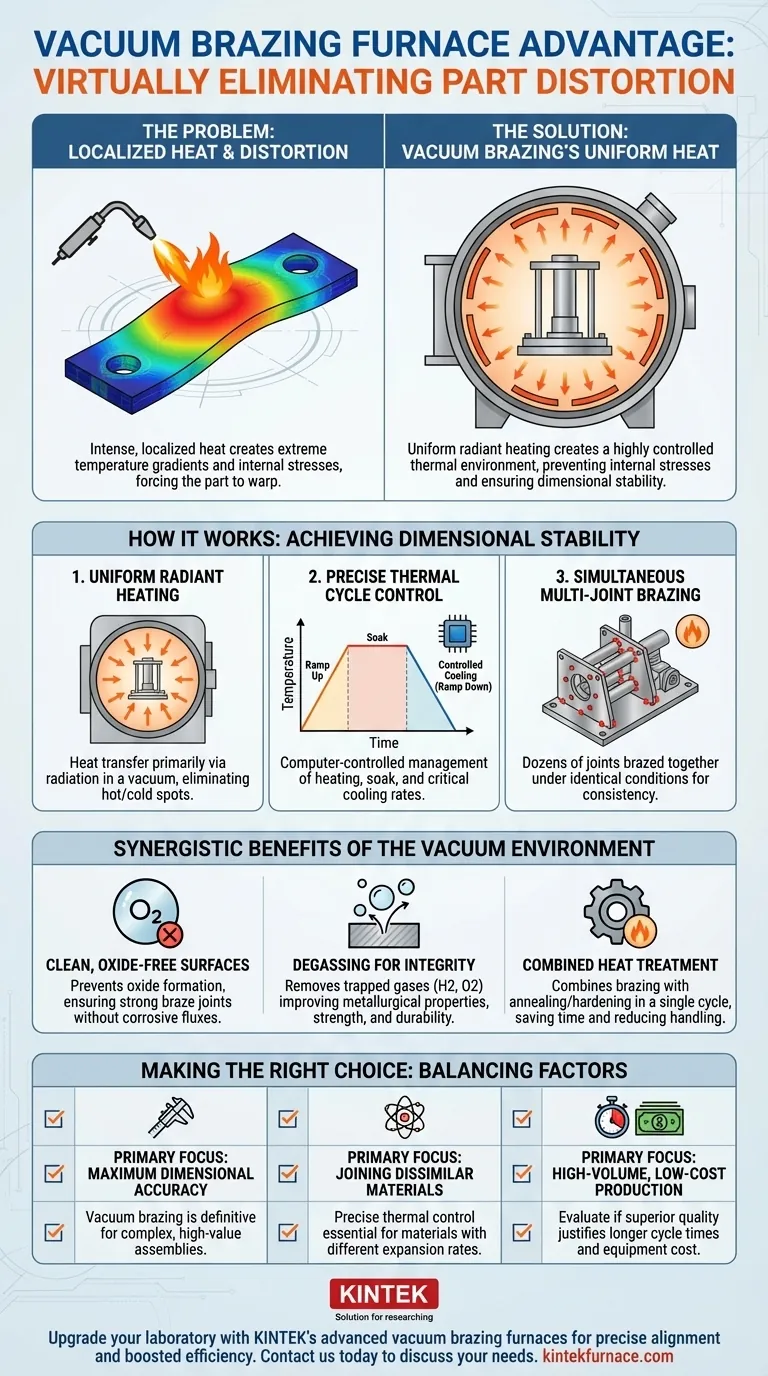

At its core, a vacuum brazing furnace provides a significant advantage by virtually eliminating part distortion. This is achieved through exceptionally uniform heating and cooling, which prevents the internal thermal stresses that cause components to warp, bend, or twist during the joining process.

The critical takeaway is that distortion is not a function of heat itself, but of uneven heat. A vacuum furnace excels by creating a highly controlled and uniform thermal environment, ensuring the entire assembly heats up and cools down as a single, stable unit.

The Physics of Distortion: Why Parts Warp

To understand why vacuum brazing is so effective, we must first understand the root cause of distortion: differential thermal expansion.

Thermal Expansion and Contraction

When a material is heated, it expands. When it cools, it contracts. If one section of a part heats or cools faster than another, it creates internal stress. This stress is what ultimately pulls the component out of its specified dimensions.

The Problem with Localized Heat

Traditional joining methods like welding or torch brazing apply intense, localized heat. This creates extreme temperature gradients—the area near the torch is molten while areas just inches away are significantly cooler. This disparity forces the part to warp as it accommodates the massive internal stresses.

How Vacuum Brazing Delivers Dimensional Stability

A vacuum furnace is not just a hot box; it is a precision instrument for managing thermal energy across an entire component or assembly.

Uniform Radiant Heating

In the near-perfect vacuum of the furnace, heat transfer occurs primarily through radiation, not convection (air currents). Heating elements surround the parts, bathing them in uniform thermal energy from all directions. This eliminates the hot spots and cold spots that are the primary drivers of distortion.

Precise Control of Thermal Cycles

Modern vacuum furnaces are computer-controlled, allowing for the precise management of the entire thermal cycle. This includes the heating rate (ramp-up), the holding time at brazing temperature (soak), and most critically, the cooling rate (ramp-down). Controlled cooling is just as important as controlled heating for preventing stress.

Joining Multiple Joints Simultaneously

Because the entire assembly is heated uniformly, it's possible to braze dozens or even hundreds of joints at once. This ensures that all joints are created under identical conditions, leading to exceptional consistency and repeatability across an entire batch of complex parts.

Synergistic Benefits of the Vacuum Environment

The low distortion is a direct result of the vacuum environment, which also provides other crucial advantages that work together to produce a superior final product.

Clean, Oxide-Free Surfaces

The vacuum removes virtually all oxygen, preventing the formation of oxides on the metal surface. This results in a bright, clean part and a stronger braze joint without the need for corrosive fluxes, which can interfere with uniform heat transfer.

Degassing for Material Integrity

The vacuum actively pulls trapped gases, like hydrogen and oxygen, out of the base materials. This "degassing" effect improves the metallurgical properties of the final assembly, increasing strength, hardness, and durability.

Combining Heat Treatment and Joining

A vacuum furnace allows you to combine brazing with a heat treatment process, such as annealing or hardening, in a single cycle. This reduces part handling, saves significant time and cost, and minimizes the risk of damage or distortion between separate process steps.

Understanding the Trade-offs

While powerful, vacuum brazing is not the solution for every application. Its precision comes with specific considerations.

Cycle Time

A vacuum brazing cycle is inherently a batch process and can be lengthy. The time required to pump the chamber down to a deep vacuum and execute a slow, controlled cooling ramp means it is generally slower than continuous or localized heating methods.

Equipment and Operational Cost

Vacuum furnaces represent a significant capital investment. They also require skilled operators and a commitment to rigorous maintenance schedules to ensure the integrity of the vacuum and the precision of the thermal controls.

Making the Right Choice for Your Application

Selecting the right joining process requires balancing the need for dimensional accuracy against production speed and cost.

- If your primary focus is maximum dimensional accuracy: Vacuum brazing is the definitive choice for complex, high-value assemblies where tight tolerances are non-negotiable.

- If your primary focus is joining dissimilar or exotic materials: The precise control over the entire thermal profile makes vacuum brazing essential for joining materials with different expansion rates.

- If your primary focus is high-volume, low-cost production of simple parts: You must evaluate if the superior quality and low distortion of vacuum brazing justify the longer cycle times compared to faster, less precise methods.

Ultimately, choosing vacuum brazing is an investment in unparalleled process control and final part quality.

Summary Table:

| Advantage | Description |

|---|---|

| Uniform Heating | Radiant heat transfer prevents hot spots, reducing internal stresses and distortion. |

| Controlled Cooling | Precise thermal cycle management minimizes warping during cooling phases. |

| Oxide-Free Surfaces | Vacuum environment eliminates oxides, ensuring clean joints and uniform heat distribution. |

| Simultaneous Joint Brazing | Allows multiple joints to be brazed at once for consistent, repeatable results. |

| Degassing Benefits | Removes trapped gases, enhancing material strength and reducing distortion risks. |

Upgrade your laboratory with KINTEK's advanced vacuum brazing furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, minimizing part distortion and boosting efficiency. Contact us today to discuss how our tailored furnace solutions can enhance your dimensional accuracy and process control!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement