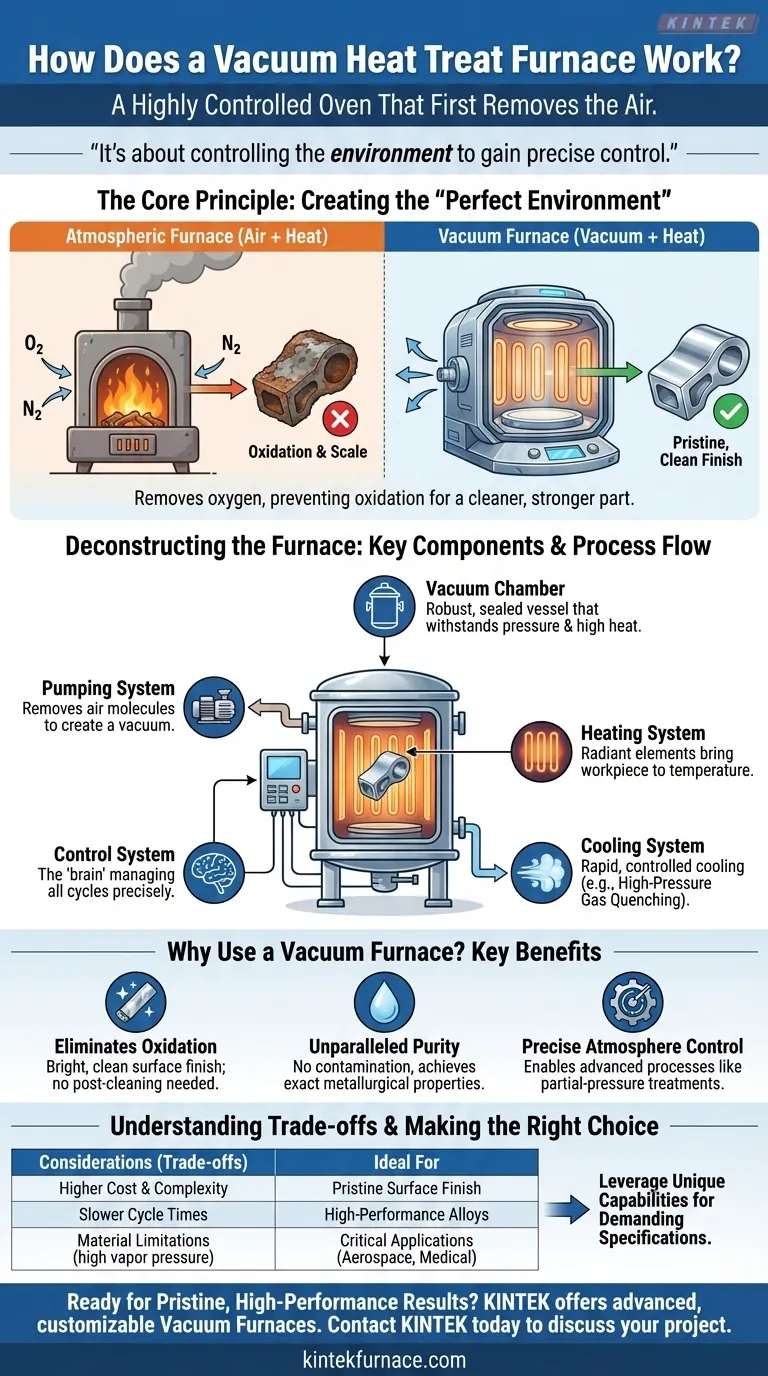

At its core, a vacuum heat treat furnace is a highly controlled oven that first removes the air. It works by creating a vacuum inside a sealed chamber before heating the material. This removal of oxygen and other atmospheric gases prevents oxidation and other unwanted chemical reactions, resulting in a cleaner, stronger, and more precisely treated part.

The crucial insight is that vacuum heat treatment isn't just about applying heat; it's about controlling the environment. By removing the atmosphere, you gain precise control over the material's final properties, achieving results that are impossible in a standard furnace.

The Purpose of the Vacuum: Creating a Perfect Environment

The decision to use a vacuum furnace is driven by the need for absolute control. The vacuum itself is not the treatment; it is the enabler of a perfect treatment environment.

Eliminating Oxidation and Contamination

When metals are heated in the presence of air, the oxygen causes a chemical reaction, forming an oxide layer or "scale" on the surface. A vacuum furnace removes virtually all the oxygen, nitrogen, and water vapor, completely preventing oxidation.

This results in a bright, clean surface finish straight out of the furnace, often eliminating the need for subsequent cleaning, grinding, or machining.

Achieving Unparalleled Purity

Beyond just oxygen, the vacuum removes other potential contaminants. This ensures that the material's chemistry remains pure and that the heat treatment process only produces the desired metallurgical changes without introducing unwanted impurities.

Enabling Precise Atmospheric Control

In some advanced processes, after the initial vacuum is pulled, a specific, pure gas like argon or nitrogen is intentionally introduced back into the chamber at a controlled pressure. This is known as a partial-pressure process.

This technique gives operators even finer control over the process, for example, using nitrogen for specific case-hardening applications on steel.

Deconstructing the Furnace: Key Components and Their Roles

A vacuum furnace is a system of integrated components working together to manage the environment and the thermal cycle.

The Vacuum Chamber

This is the sealed, robust steel vessel that contains the workpiece. It is designed to withstand both extreme external atmospheric pressure when under vacuum and high internal temperatures.

The Pumping System

This is the heart of the vacuum creation. It typically consists of a series of pumps, such as a mechanical "roughing" pump and a "diffusion" or "turbomolecular" pump, that work in stages to remove air molecules from the chamber.

The Heating System

Heating elements, often made of graphite or refractory metals, are located inside the chamber. They generate radiant heat to bring the workpiece up to the required temperature, which can exceed 2,000°F (1,093°C). The control system precisely manages the power to these elements.

The Control System

This is the brain of the operation. A sophisticated computer control system monitors and regulates the vacuum level, temperature ramp rates, soak times, and cooling cycles according to a pre-programmed recipe for the specific material being treated.

The Cooling & Quenching System

After heating, the material must be cooled at a specific rate to lock in the desired properties. Vacuum furnaces accomplish this through methods like high-pressure gas quenching (HPGQ), where an inert gas like argon or nitrogen is blasted into the chamber. Some furnaces are also equipped to perform oil or water quenching.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the universal solution. Objectivity requires acknowledging its limitations.

Cost and Complexity

Vacuum furnaces are significantly more complex and expensive to purchase, operate, and maintain than their atmospheric counterparts. The vacuum pumps, seals, and control systems require specialized knowledge and upkeep.

Slower Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to every cycle. For high-volume, low-margin parts where cycle time is critical, this can be a significant drawback.

Material Limitations

Certain materials are not suitable for vacuum processing. Materials with high vapor pressures (like zinc, lead, or cadmium) can "outgas" during the heating cycle, meaning they turn into a vapor that contaminates the furnace and the workpiece.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your material requirements and project goals.

- If your primary focus is a pristine surface finish and preventing oxidation: Vacuum treatment is the superior choice, especially for parts that cannot be easily cleaned after processing.

- If your primary focus is achieving high-performance metallurgical properties: The precise environmental control of a vacuum furnace is essential for advanced alloys used in aerospace, medical, and high-performance tooling.

- If your primary focus is cost-effective bulk processing of simple steels: A traditional atmospheric furnace may be more suitable, provided a small amount of surface scale is acceptable or can be removed.

By understanding how a vacuum furnace works, you can leverage its unique capabilities to achieve demanding material specifications with unparalleled precision.

Summary Table:

| Key Component | Primary Function |

|---|---|

| Vacuum Chamber | Sealed vessel that withstands pressure and high temperatures. |

| Pumping System | Removes air molecules to create a vacuum environment. |

| Heating System | Radiant heating elements bring the workpiece to precise temperatures. |

| Control System | The 'brain' that manages vacuum, temperature, and cooling cycles. |

| Cooling System | Cools the material at a controlled rate (e.g., High-Pressure Gas Quenching). |

| Key Advantage | Result |

| Eliminates Oxidation | Bright, clean surface finish; no post-treatment cleaning needed. |

| Precise Atmosphere Control | Achieves exact metallurgical properties for advanced alloys. |

Ready to achieve pristine, high-performance results with a vacuum furnace?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Our expertise in high-temperature furnaces, including our range of Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Whether you are in aerospace, medical, or tooling, our team can help you select or customize the perfect furnace for your application. Contact KINTEL today to discuss your project and discover the difference precision engineering can make.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing