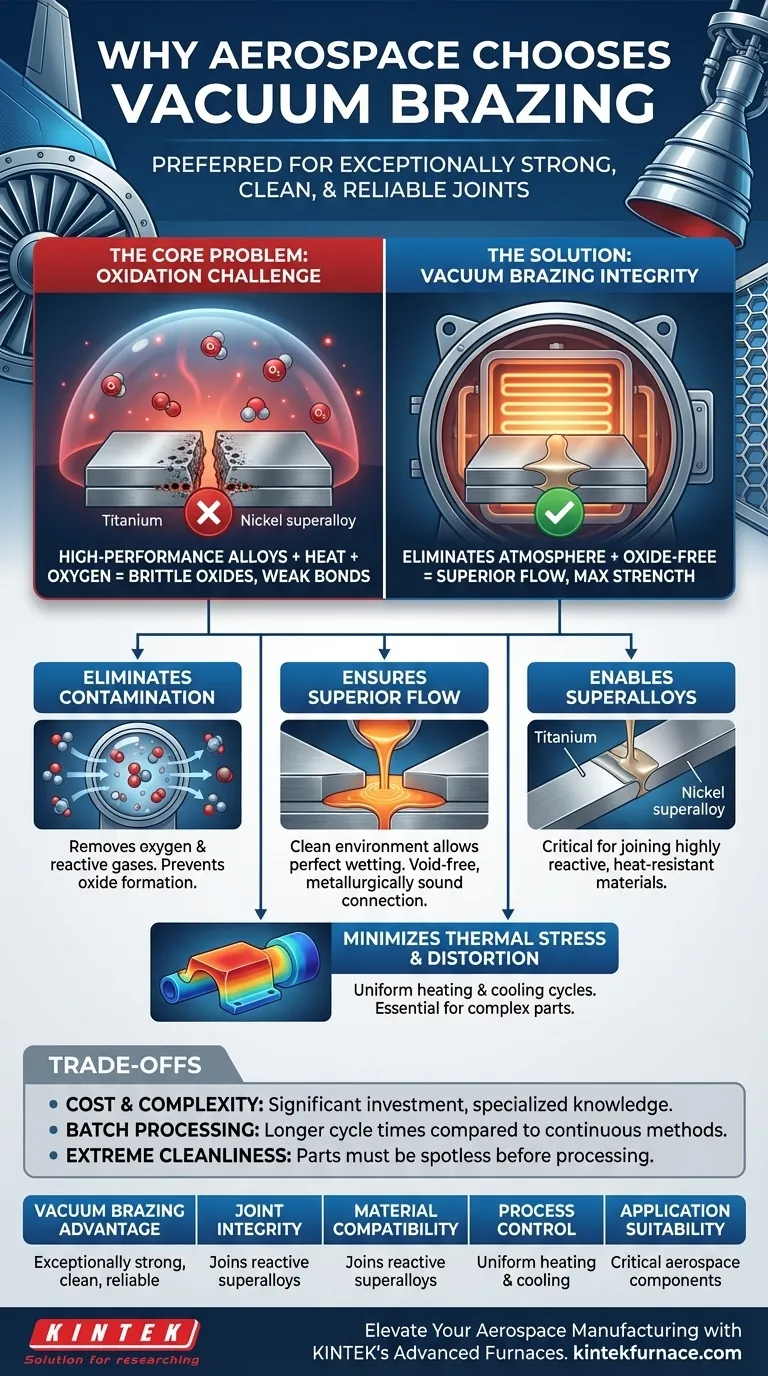

In short, vacuum brazing is preferred in aerospace because it produces exceptionally strong, clean, and reliable joints. This process is uniquely capable of joining the lightweight, high-performance alloys used in critical components like turbine blades and heat exchangers without compromising their material properties, ensuring they can withstand extreme operational environments.

The core reason for its preference is not just an improvement in quality, but a fundamental necessity. A vacuum environment is the only way to prevent catastrophic oxidation and contamination when joining the highly reactive, heat-resistant superalloys that are foundational to modern aviation and spaceflight.

The Core Problem: Why Standard Brazing Fails Aerospace

To understand the value of vacuum brazing, we must first understand the unique challenges of aerospace manufacturing. The demands for performance, safety, and weight reduction are absolute.

The Challenge of High-Performance Alloys

Aerospace engineers rely on materials like titanium alloys and nickel-based superalloys. These materials are chosen for their incredible strength-to-weight ratio and ability to perform at extremely high temperatures.

However, these materials have a significant downside: they are highly reactive with gases in the atmosphere, especially oxygen, particularly when heated.

The Threat of Oxidation

When heated in the presence of air, these advanced alloys rapidly form brittle oxides on their surfaces.

If you attempt to braze a joint in these conditions, these oxide layers prevent the filler metal from properly wetting and flowing into the joint. The result is a weak, incomplete bond riddled with inclusions that is guaranteed to fail under stress.

The Need for Absolute Purity

Beyond oxygen, even trace amounts of other atmospheric gases or surface contaminants can introduce impurities into the joint. In aerospace, where a single failure point can be catastrophic, such contamination is unacceptable.

How Vacuum Brazing Delivers Unmatched Integrity

Vacuum furnace brazing directly solves the fundamental problems of oxidation and contamination by removing the atmosphere from the equation.

It Eliminates Atmospheric Contamination

By performing the process in a high vacuum, the furnace removes virtually all oxygen and other reactive gases. This prevents the formation of oxide layers, allowing the brazing filler metal to interact directly with the pure parent metals.

It Ensures Superior Filler Metal Flow

In the clean, oxide-free environment of a vacuum, the molten filler metal flows perfectly and completely throughout the joint via capillary action. This creates a void-free, metallurgically sound connection with maximum strength and ductility.

It Enables the Use of Advanced Superalloys

Vacuum brazing isn't just a better way to join standard metals; it is the enabling technology that allows for the successful joining of reactive superalloys. Without it, creating complex assemblies from these materials would be impossible.

It Minimizes Thermal Stress and Distortion

A vacuum furnace provides extremely uniform and precisely controlled heating and cooling cycles. This slow, even process minimizes internal stresses and distortion, which is critical when manufacturing complex and dimensionally sensitive parts like turbine components or honeycomb panels.

Understanding the Trade-offs

While its benefits are clear, vacuum brazing is not without its practical considerations. It is a deliberate choice made when performance requirements justify the investment.

The Cost and Complexity

Vacuum furnaces are significant capital investments. They are complex machines that require specialized knowledge to operate and maintain, making the process more expensive than standard atmospheric brazing.

The Batch Processing Limitation

Vacuum brazing is a batch process. Parts must be loaded, the chamber sealed, a vacuum pulled, the heating cycle run, and the parts cooled before they can be removed. This results in longer cycle times compared to continuous brazing methods.

The Requirement for Extreme Cleanliness

The process demands that parts be impeccably clean before entering the furnace. Any oils, residues, or contaminants on the components can "outgas" in the vacuum, ruining the process and potentially contaminating the entire furnace.

Making the Right Choice for Your Application

Selecting a joining process requires aligning its capabilities with your primary engineering goals.

- If your primary focus is mission-critical reliability and high-temperature performance: Vacuum brazing is the non-negotiable standard for parts like turbine blades, fuel injectors, and engine components.

- If your primary focus is achieving the maximum strength-to-weight ratio in complex assemblies: The uniformity and cleanliness of vacuum brazing are essential for creating robust honeycomb structures and lightweight frames.

- If your primary focus is cost-effective joining of common, less-reactive metals for non-structural parts: Simpler controlled-atmosphere or torch brazing methods may be a more practical and economical choice.

Ultimately, adopting vacuum brazing is a strategic decision to prioritize metallurgical perfection and absolute reliability where failure is not an option.

Summary Table:

| Aspect | Vacuum Brazing Advantage |

|---|---|

| Joint Integrity | Produces exceptionally strong, clean, and reliable joints without oxidation or contamination. |

| Material Compatibility | Enables joining of reactive superalloys like titanium and nickel-based alloys. |

| Process Control | Ensures uniform heating and cooling, minimizing thermal stress and distortion. |

| Application Suitability | Ideal for critical aerospace components such as turbine blades and heat exchangers. |

Elevate your aerospace manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum brazing systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental requirements, delivering unmatched joint integrity and performance. Contact us today to discuss how we can support your mission-critical applications!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures