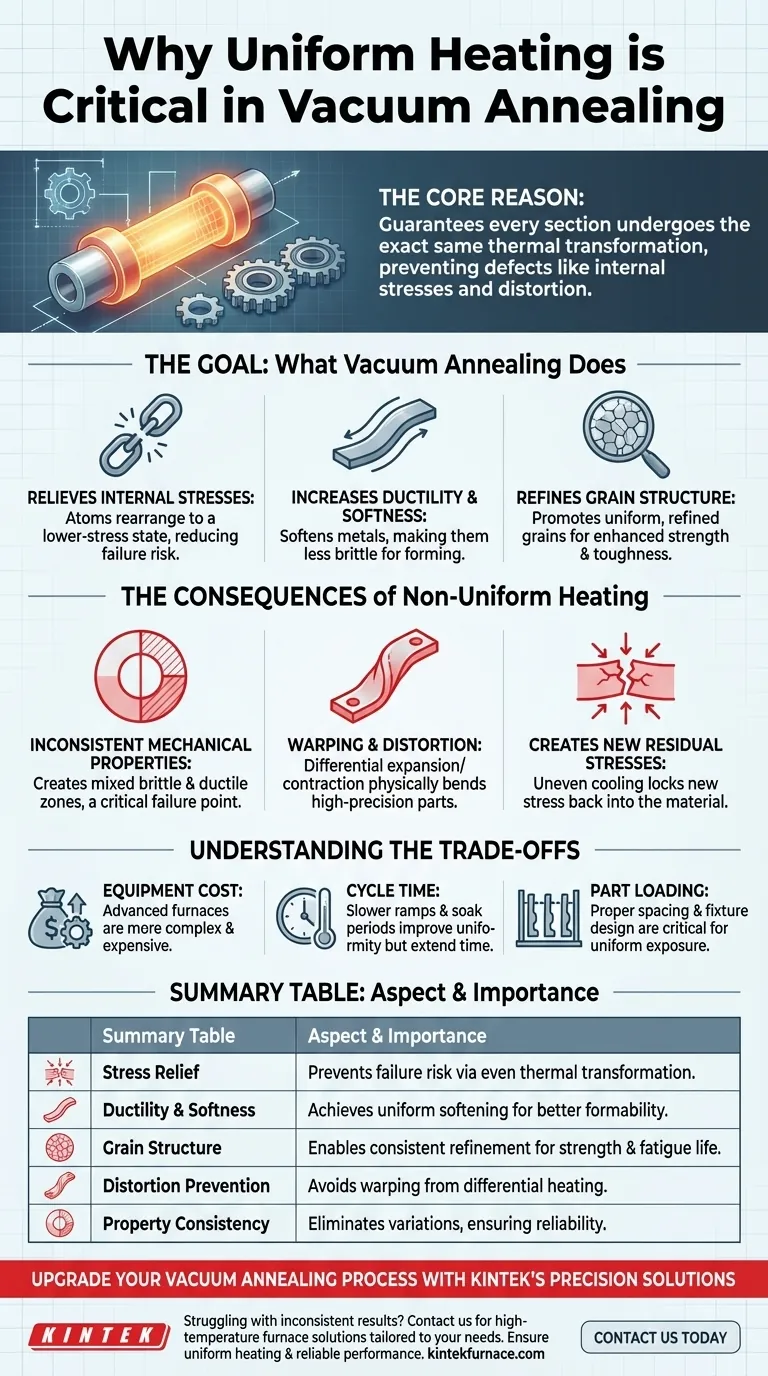

At its core, uniform heating is essential in vacuum annealing because it guarantees that every section of a component undergoes the exact same thermal transformation. This consistency prevents the creation of internal stresses, physical distortion, and unpredictable variations in material properties, which are the very defects that annealing is meant to eliminate.

The fundamental purpose of annealing is to achieve a precise and predictable change in a material's microstructure. Non-uniform heating introduces uncontrolled variables, turning a precise process into a gamble and risking part failure, dimensional inaccuracies, and inconsistent performance.

The Goal: What Vacuum Annealing Actually Does

Vacuum annealing is a heat treatment process performed in a vacuum to prevent oxidation. Its primary goals are to precisely manipulate a material's internal structure to improve its physical and mechanical properties.

Relieving Internal Stresses

Manufacturing processes like machining, welding, or cold working introduce significant stress into a material's atomic lattice. Annealing provides the thermal energy for atoms to rearrange into a lower-stress state, drastically reducing the risk of premature failure or distortion.

Increasing Ductility and Softness

The process softens metals, making them more ductile and less brittle. This is critical for parts that need to be bent, formed, or further machined without cracking.

Refining Grain Structure

Heating allows for the recrystallization of the material's grain structure. Controlling this process results in a more uniform and refined grain size, which typically enhances strength, toughness, and fatigue life.

The Consequences of Non-Uniform Heating

When temperature varies across a component during annealing, it undermines the entire purpose of the process. The consequences range from minor inconsistencies to catastrophic failure.

Inconsistent Mechanical Properties

If one area of a part is hotter than another, it will anneal to a different degree. This can result in a single component having hard, brittle zones right next to soft, ductile ones, creating a critical point of failure under load.

Warping and Distortion

Materials expand when heated and contract when cooled. If one section of a part heats or cools faster than an adjacent section, this differential expansion and contraction will physically bend or twist the part, a phenomenon known as warping. For high-precision components, this renders them useless.

Creation of New Residual Stresses

Ironically, poor annealing can create new internal stresses instead of relieving them. As different sections cool at different rates, they pull against each other, locking stress back into the material and potentially causing micro-cracks that grow over time.

Understanding the Trade-offs

Achieving perfect temperature uniformity is an engineering challenge with inherent compromises. Understanding these helps in selecting the right process for a specific application.

Equipment Cost and Complexity

Furnaces designed for high temperature uniformity are more complex and expensive. They require multiple, independently controlled heating zones, advanced sensor arrays, and sophisticated control logic to maintain an even temperature throughout the chamber.

Cycle Time vs. Quality

A common method to improve uniformity is to use a slower temperature ramp rate and add "soak" periods where the temperature is held constant. This allows thermal energy to equalize throughout the workload but also extends the total cycle time, impacting throughput and cost.

The Critical Role of Part Loading

Even the most advanced furnace can be defeated by improper loading. If parts are packed too densely or shield each other from heat sources, cold spots are inevitable. Proper fixture design and part spacing are critical for ensuring uniform heat exposure.

Making the Right Choice for Your Goal

The required level of temperature uniformity is dictated entirely by the end-use of the component.

- If your primary focus is high-performance, critical components (aerospace, medical): The highest possible degree of temperature uniformity is non-negotiable to ensure material reliability and safety.

- If your primary focus is general-purpose parts with wider tolerances: A standard furnace may provide an acceptable balance between cost and performance, as minor variations in properties are less critical.

- If you are experiencing part distortion or inconsistent test results: Non-uniform heating in your current annealing process is a primary suspect and a thermal survey of your furnace is warranted.

Ultimately, controlling temperature uniformity is about controlling the outcome, ensuring every part meets its required specification without compromise.

Summary Table:

| Aspect | Importance in Vacuum Annealing |

|---|---|

| Stress Relief | Prevents internal stresses and reduces failure risk by ensuring even thermal transformation. |

| Ductility & Softness | Achieves uniform material softening for better formability and reduced brittleness. |

| Grain Structure | Enables consistent grain refinement to enhance strength, toughness, and fatigue life. |

| Distortion Prevention | Avoids warping and physical deformation caused by differential heating and cooling. |

| Property Consistency | Eliminates variations in mechanical properties, ensuring part reliability and performance. |

Upgrade Your Vacuum Annealing Process with KINTEK's Precision Solutions

Struggling with inconsistent results or part failures due to non-uniform heating? At KINTEK, we leverage exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored for your lab's needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed with strong deep customization capabilities to precisely meet your unique experimental requirements. Ensure every component achieves uniform heating and reliable performance. Contact us today to discuss how our furnaces can optimize your annealing processes and enhance material quality!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control