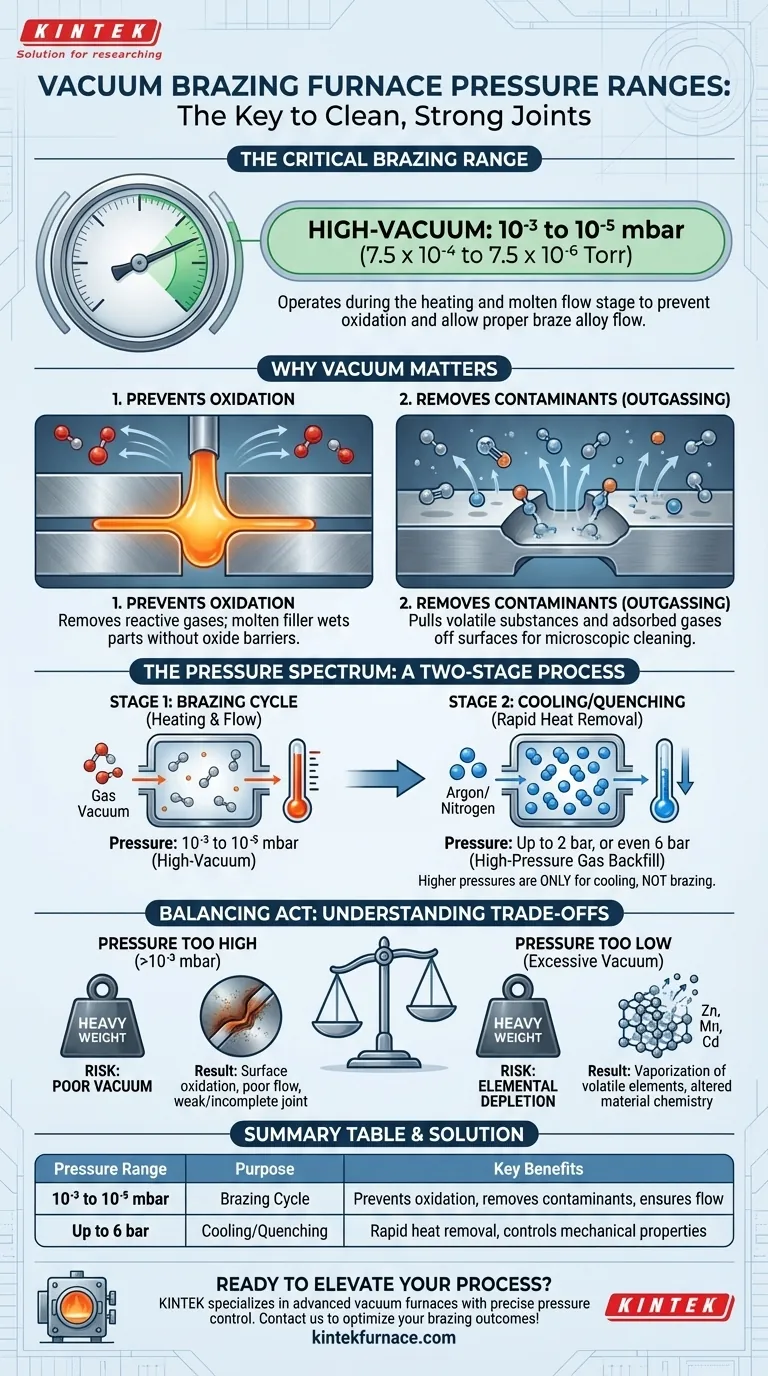

To be precise, a vacuum brazing furnace typically operates within a high-vacuum range of 10⁻³ to 10⁻⁵ millibars (mbar) during the actual brazing cycle. This pressure level, equivalent to approximately 7.5 x 10⁻⁴ to 7.5 x 10⁻⁶ Torr, is critical for creating an environment that is clean enough to prevent oxidation and allow the braze filler metal to flow properly into the joint.

The specific pressure level in a vacuum furnace is not arbitrary; it is a precisely controlled parameter designed to create a chemically active environment that removes contaminants and oxides, ensuring the metallurgical integrity of the brazed joint.

The Purpose of Vacuum in Brazing

The primary goal of vacuum brazing is to create a strong, clean, and hermetic joint between two or more metal components. Achieving this requires an environment that is fundamentally different from brazing in open air.

Preventing Oxidation

The most critical function of the vacuum is to remove oxygen and other reactive gases from the furnace chamber. When heated, most metals will rapidly form oxides on their surface, which act as a barrier that prevents the molten braze filler metal from wetting the parts and flowing into the joint via capillary action.

By evacuating the chamber to a high vacuum, the quantity of oxygen molecules is reduced so drastically that oxidation cannot occur, even at the high temperatures required for brazing.

Removing Volatiles and Contaminants

The vacuum actively pulls volatile substances and adsorbed gases off the surfaces of the parts being brazed. This process, known as outgassing, cleans the joint surfaces at a microscopic level.

This ensures that no trapped contaminants interfere with the formation of a strong, continuous metallurgical bond between the filler metal and the base metals.

Understanding the Different Pressure Ranges

A modern vacuum furnace operates at different pressures during different stages of the process. Confusing these stages is a common point of misunderstanding.

The High-Vacuum Brazing Range (10⁻³ to 10⁻⁵ mbar)

This is the pressure range where the heating and molten flow of the braze alloy occurs. It is considered a high-vacuum environment.

This level is low enough to prevent the oxidation of common engineering materials like stainless steels, nickel alloys, and copper.

Higher Pressures for Cooling and Quenching

After the brazing process is complete and the filler metal has solidified, the assembly must be cooled. Some furnaces use a high-pressure gas quench for this step.

The furnace is backfilled with an inert gas, like argon or nitrogen, to pressures of 2 bar or even up to 6 bar. This high-pressure gas circulates rapidly, removing heat much faster than cooling in a vacuum could. This is essential for achieving specific mechanical properties or grain structures in the final assembly.

These higher pressures are only used for cooling and are not the pressure at which brazing takes place.

Understanding the Trade-offs

Choosing the right pressure is a matter of balancing competing factors. It is not always a case of "the lower the pressure, the better."

Risk of Poor Vacuum (Pressure Too High)

If the vacuum level is not low enough (e.g., higher than 10⁻³ mbar), residual oxygen will remain in the chamber. This leads to surface oxidation on the parts, poor braze flow, and ultimately a weak or incomplete joint.

The result is a high rate of rejected parts and unreliable performance.

Risk of Excessive Vacuum (Pressure Too Low)

For certain materials, an extremely low pressure can be detrimental. Some metal alloys contain elements with a high vapor pressure, meaning they can "boil off" or sublimate from the base metal or filler alloy under high heat and very low pressure.

Elements like zinc, manganese, or cadmium are susceptible to this. This phenomenon, known as elemental depletion, can alter the chemistry and performance of both the base material and the braze joint. In these cases, brazing may be performed at a slightly higher pressure or with a partial pressure of an inert gas to suppress this vaporization.

Making the Right Choice for Your Goal

The optimal pressure setting depends entirely on the materials being joined and the desired outcome.

- If your primary focus is brazing standard stainless steel or nickel alloys: The standard high-vacuum range of 10⁻³ to 10⁻⁵ mbar is the correct environment for achieving clean, oxide-free joints.

- If your primary focus is brazing materials with volatile elements (e.g., some copper or aluminum alloys): You must carefully control the pressure to prevent elemental depletion, which may require operating at the higher end of the vacuum range or using a partial pressure backfill.

- If your primary focus is controlling the final mechanical properties: A furnace with a high-pressure gas quench capability is essential for rapid cooling after the brazing cycle is complete.

Ultimately, controlling the furnace pressure is fundamental to mastering the vacuum brazing process.

Summary Table:

| Pressure Range | Purpose | Key Benefits |

|---|---|---|

| 10⁻³ to 10⁻⁵ mbar | Brazing cycle | Prevents oxidation, removes contaminants, ensures proper braze flow |

| Up to 6 bar | Cooling/quenching | Rapid heat removal, controls mechanical properties |

Ready to elevate your vacuum brazing process? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces with precise pressure control. Our deep customization capabilities ensure your furnace meets unique experimental needs, delivering clean, strong joints for materials like stainless steel and nickel alloys. Contact us today to discuss how we can optimize your brazing outcomes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments