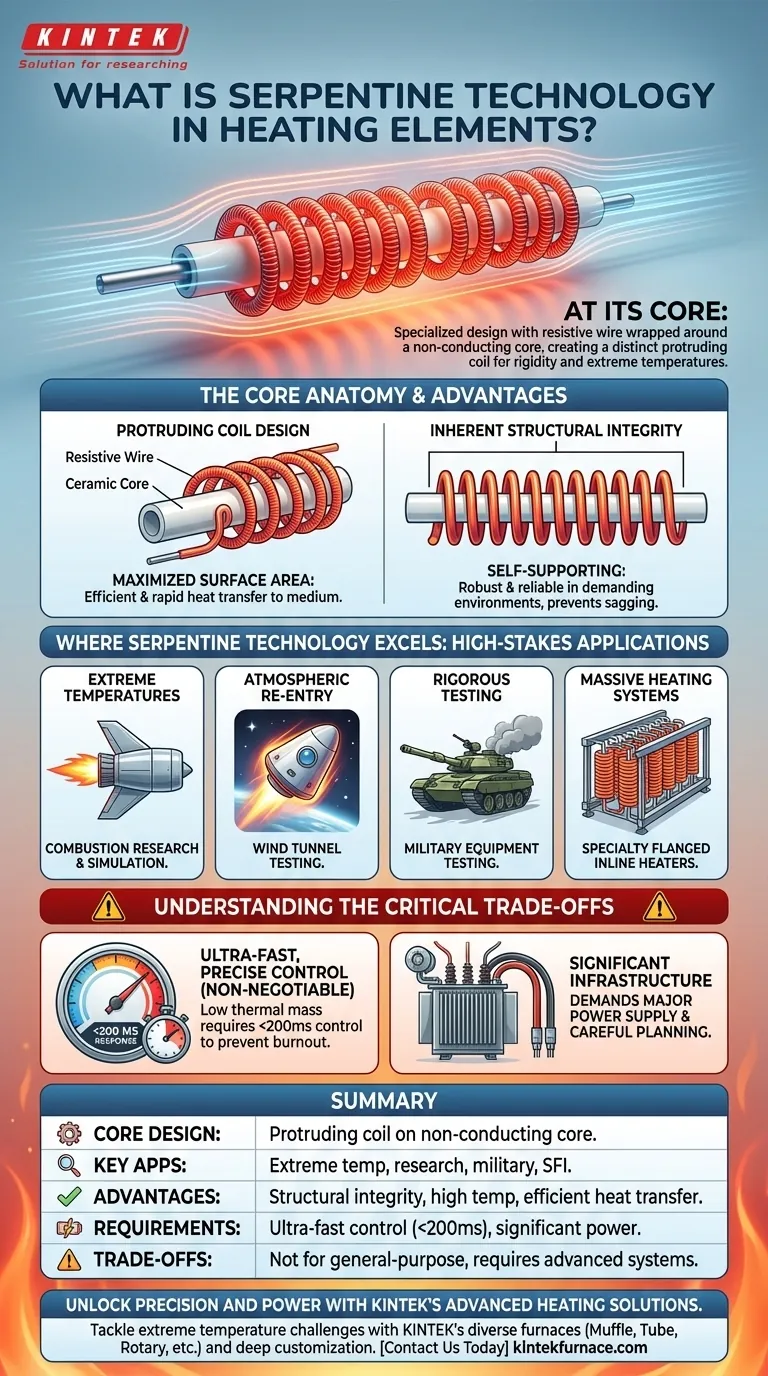

At its core, Serpentine Technology is a specialized design for electric heating elements where resistive wire is wrapped around a non-conducting core. This creates a distinct protruding, or serpentine, coil pattern that provides exceptional structural rigidity and the ability to operate at very high temperatures.

Serpentine Technology is not a universal solution for heating. It is an engineered system for extreme, high-stakes applications where high temperatures are paramount, but it carries a critical dependency on ultra-fast, precise temperature control to prevent self-destruction.

The Core Anatomy of a Serpentine Element

To understand why this technology is used, we must first examine its unique construction. It differs fundamentally from more common heating element designs.

The Protruding Coil Design

The defining feature is the wire element itself, which is wrapped tightly around a ceramic or other non-conductive core. This creates a stiff, self-contained coil that protrudes into the air or gas stream.

This design maximizes the surface area of the heating wire exposed to the medium being heated, which allows for very efficient and rapid heat transfer.

Inherent Structural Integrity

Unlike many conventional heating elements that require complex internal suspension systems to prevent sagging or shorts, the Serpentine element's structure is inherently rigid.

This self-supporting nature makes it robust and reliable in demanding physical environments, as it maintains its shape and integrity without additional supports.

Where Serpentine Technology Excels: High-Stakes Applications

The unique properties of Serpentine elements make them suitable for a narrow but critical range of applications where other technologies fail.

Reaching Extreme Temperatures

This technology is a primary choice for processes requiring extremely high air or gas temperatures. Its robust design allows it to operate reliably under conditions that would quickly degrade lesser elements.

Common use cases include advanced combustion research, simulating atmospheric re-entry conditions in wind tunnels, and rigorous military equipment testing.

Building Massive Heating Systems

Individual Serpentine elements can be assembled into very large arrays known as Specialty Flanged Inline (SFI) heaters.

These systems can deliver immense thermal energy for large-scale industrial processes, forming the core of massive air and gas heating infrastructure.

Understanding the Critical Trade-offs

The high performance of Serpentine Technology comes with significant and non-negotiable operational requirements. Ignoring these constraints leads to rapid and catastrophic failure.

The Non-Negotiable Need for Precision Control

This is the technology's single greatest vulnerability. The elements have very low thermal mass and react incredibly quickly, necessitating a control system with a response time of 200 milliseconds or faster.

Without this precise, high-speed control, the element can easily overheat and burn out in a fraction of a second. It is a high-performance engine that requires an equally high-performance computer to manage it.

Significant Infrastructure Requirements

Deploying large-scale Serpentine heaters, particularly SFI units, is a major undertaking. These systems demand a significant power infrastructure to support their high wattage.

This is not a simple "plug-and-play" solution; it requires careful planning of the electrical supply, transformers, and control circuitry.

Making the Right Choice for Your Application

Selecting the right heating technology depends entirely on your specific goal and operational constraints.

- If your primary focus is extreme temperature simulation: Serpentine Technology is a leading choice, provided you can design and implement the required high-speed control systems.

- If your primary focus is general-purpose process heating: More forgiving and less complex technologies, such as tubular or cartridge heaters, are almost always a more practical and cost-effective choice.

- If your primary focus is durability in a high-flow environment: The inherent structural rigidity of Serpentine elements makes them a strong candidate worth investigating for their physical robustness.

Ultimately, understanding Serpentine Technology is about recognizing its power in specialized scenarios while respecting its demanding operational requirements.

Summary Table:

| Aspect | Description |

|---|---|

| Core Design | Resistive wire wrapped around a non-conducting core, creating a protruding coil pattern for high structural rigidity and efficient heat transfer. |

| Key Applications | Extreme temperature processes like combustion research, wind tunnel simulations, military testing, and large-scale industrial heating systems (e.g., SFI heaters). |

| Advantages | Exceptional structural integrity, ability to operate at very high temperatures, efficient heat transfer due to maximized surface area, and suitability for large arrays. |

| Critical Requirements | Ultra-fast, precise temperature control (response time ≤ 200 ms) to prevent burnout; significant power infrastructure for large-scale deployments. |

| Trade-offs | Not suitable for general-purpose heating; requires advanced control systems and careful planning, making it less practical for non-specialized uses. |

Unlock Precision and Power with KINTEK's Advanced Heating Solutions

Are you tackling extreme temperature challenges in your lab or industrial process? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

Whether you need robust heating elements for high-stakes applications or tailored systems for demanding environments, KINTEK delivers reliability and innovation. Contact us today to discuss how our expertise can enhance your operations and drive your projects forward!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer