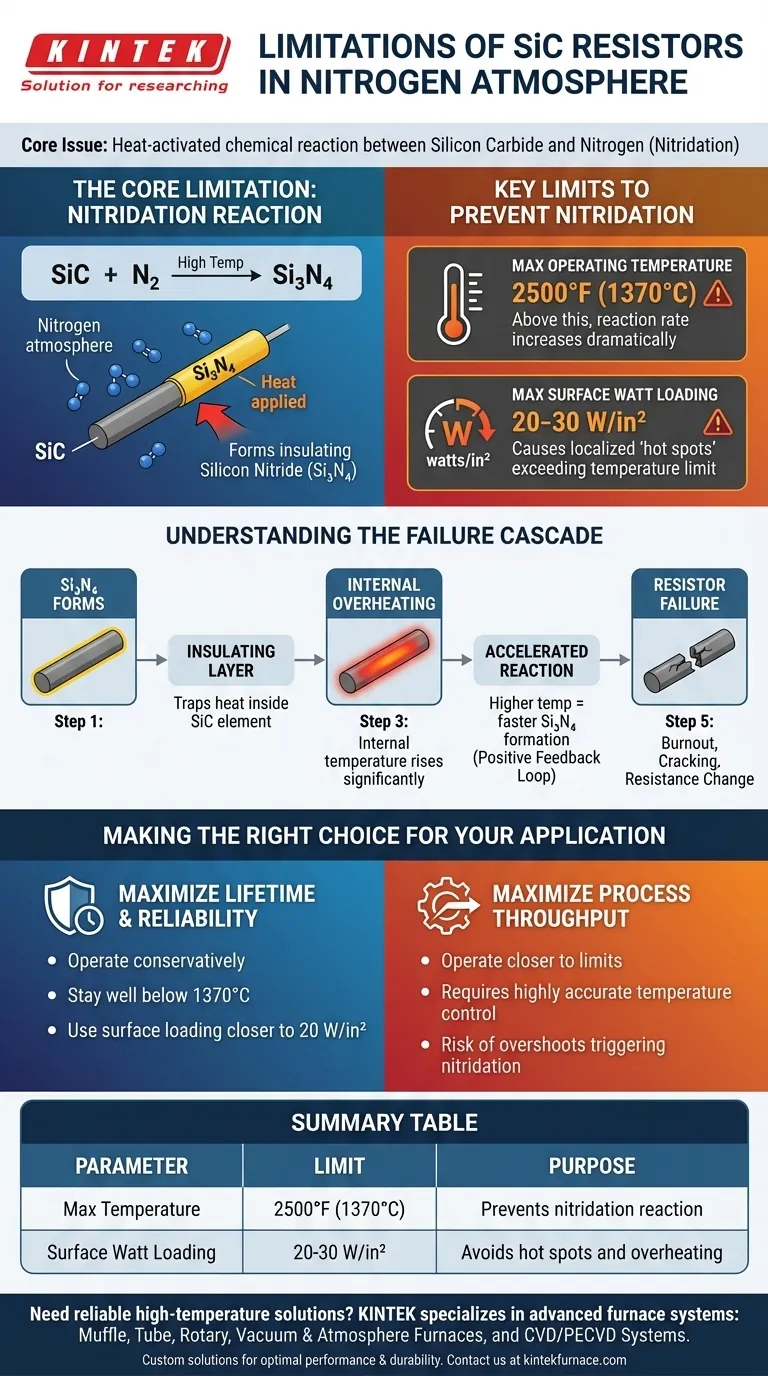

In a nitrogen atmosphere, the use of silicon carbide (SiC) heating elements is constrained by a maximum operating temperature and a maximum surface power density. Specifically, the limits are 2500°F (1370°C) and a surface watt loading of 20 to 30 watts per square inch. Exceeding these thresholds triggers a destructive chemical reaction that leads to premature element failure.

The core issue is not the nitrogen itself, but a heat-activated chemical reaction between the silicon carbide and the nitrogen. These operational limits are designed to prevent this reaction, known as nitridation, which irreversibly damages the resistor.

The Core Limitation: The Nitridation Reaction

To operate SiC elements reliably in nitrogen, you must understand the underlying chemical process that defines their performance limits. The entire operational strategy revolves around preventing this single reaction.

What is Nitridation?

At sufficiently high temperatures, the silicon in the SiC element will react directly with the nitrogen (N₂) in the atmosphere.

This reaction forms a new compound, silicon nitride (Si₃N₄), on the surface of the heating element.

Why the Temperature Limit Matters

This nitridation reaction is thermally activated. Below 2500°F (1370°C), the rate of reaction is negligible and allows for a long operational life.

Above this temperature, the reaction rate increases dramatically. The higher the temperature, the faster the silicon nitride layer forms, and the quicker the element is damaged.

The Role of Surface Watt Loading

Surface watt loading is a measure of power density (watts per square inch) on the element's surface. It is the primary factor that determines the element's surface temperature.

Even if the furnace's ambient temperature is below the limit, a high watt loading can create localized "hot spots" on the element surface that exceed 1370°C. This is why managing both ambient temperature and watt loading is critical.

Understanding the Failure Cascade

The formation of silicon nitride initiates a vicious cycle that quickly leads to the element's destruction. Understanding this process helps in diagnosing and preventing failures.

Formation of an Insulating Layer

Silicon nitride is a very effective thermal insulator. As it forms on the element's surface, it acts like a blanket, trapping heat inside the SiC element.

The Vicious Cycle of Overheating

As heat becomes trapped, the internal temperature of the element rises significantly, even if the surface temperature remains constant.

This higher internal temperature accelerates the nitridation reaction, which in turn creates a thicker insulating layer. This positive feedback loop causes the element's temperature to spiral upwards uncontrollably.

The End Result: Resistor Failure

This rapid, localized overheating ultimately leads to the failure of the heating element. The element may burn out, crack from thermal stress, or its resistance may change so drastically that it no longer heats effectively.

Making the Right Choice for Your Application

Your operational strategy depends entirely on your process goals. Balancing performance against equipment longevity is key when operating SiC elements in nitrogen.

- If your primary focus is maximum lifetime and reliability: Operate your elements conservatively, staying well below the 1370°C limit and using a surface watt loading closer to 20 W/in².

- If your primary focus is process throughput: You can operate closer to the maximum limits, but you must invest in highly accurate temperature control and monitoring systems to prevent overshoots that could trigger nitridation.

Understanding this chemical limitation is the key to designing a reliable and effective high-temperature nitrogen process.

Summary Table:

| Parameter | Limit | Purpose |

|---|---|---|

| Max Temperature | 2500°F (1370°C) | Prevents nitridation reaction |

| Surface Watt Loading | 20-30 W/in² | Avoids hot spots and overheating |

Need reliable high-temperature solutions for your lab? KINTEK specializes in advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs, ensuring optimal performance and durability in nitrogen atmospheres. Contact us today to discuss how we can enhance your processes!

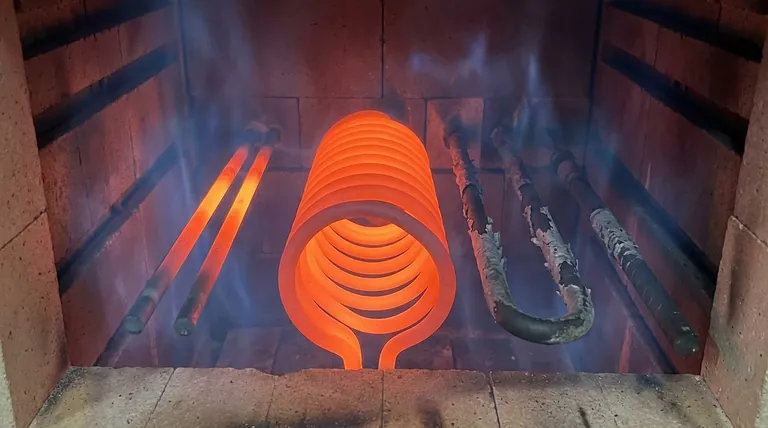

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability