In modern melting applications, IGBT (Insulated Gate Bipolar Transistor) modules deliver significant cost savings through a combination of superior energy efficiency, simplified system design, and enhanced operational control. They directly reduce expenses by consuming less power, eliminating the need for expensive auxiliary components like snubber circuits, and enabling the use of simpler, more cost-effective driver circuits.

The true value of IGBTs lies beyond simple component savings. They represent a fundamental technological shift that reduces both initial capital expenditure (CapEx) and long-term operational expenditure (OpEx), making the entire melting process more economically viable and reliable.

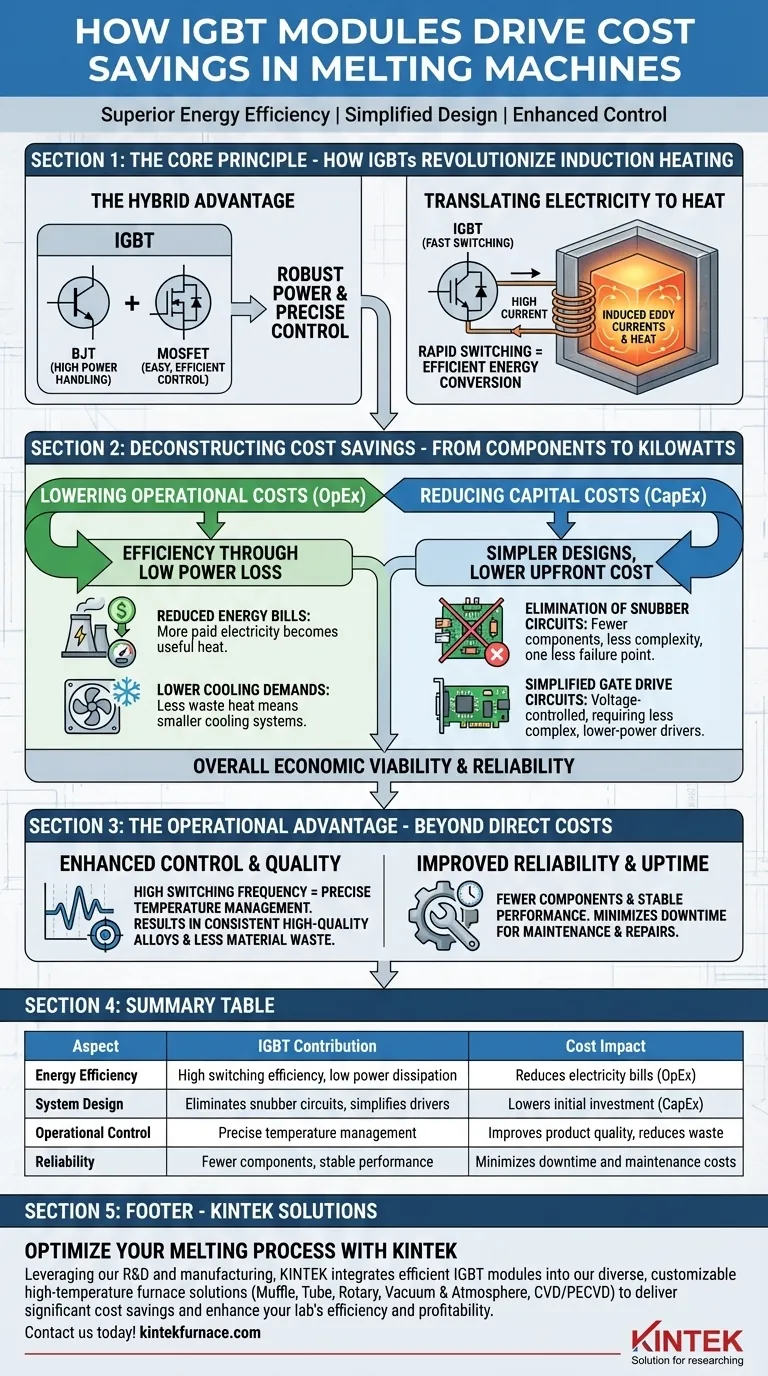

The Core Principle: How IGBTs Revolutionize Induction Heating

To understand the cost savings, we must first understand why IGBTs are uniquely suited for high-power switching applications like induction melting.

The Hybrid Advantage: Combining Power and Control

An IGBT is essentially a hybrid device. It combines the high current-handling capability of a traditional Bipolar Junction Transistor (BJT) with the simple, low-power voltage control of a Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET).

This combination provides the best of both worlds: robust power management that is easy and efficient to control.

Translating Electricity to Heat with Precision

In an induction furnace, IGBT modules act as incredibly fast switches. They are turned on and off by a gate drive circuit, allowing high current to flow through a coil surrounding the metal.

This rapid switching induces powerful eddy currents within the metal itself, generating immense heat and causing it to melt. The speed and precision of the IGBT are what make this energy conversion so effective.

Deconstructing the Cost Savings: From Components to Kilowatts

The economic benefits of IGBTs can be broken down into two main categories: lower long-term operating costs and reduced upfront investment.

Lowering Operational Costs (OpEx) Through Efficiency

IGBTs are defined by their high efficiency. This stems directly from their low on-state voltage drop and minimal power dissipation.

In practical terms, this means very little electrical energy is wasted as heat within the IGBT itself. This efficiency leads to two major operational savings:

- Reduced Energy Bills: Less wasted power means more of the electricity you pay for is converted directly into useful heat for melting the metal.

- Lower Cooling Demands: Because the modules generate less waste heat, the requirements for complex and power-hungry cooling systems are significantly reduced.

Reducing Capital Costs (CapEx) with Simpler Designs

The inherent design of IGBTs simplifies the entire furnace power supply, reducing the initial purchase and engineering costs.

Elimination of Snubber Circuits: Older technologies, such as SCRs (Silicon-Controlled Rectifiers), often required complex and costly snubber circuits to protect them from the voltage spikes that occur during high-power switching. IGBTs are far more robust in this regard, making these circuits unnecessary in most designs. This removes a component, an engineering task, and a potential point of failure.

Simplified Gate Drive Circuits: Because IGBTs are voltage-controlled, the circuits required to switch them on and off are much simpler and lower-power than the current-controlled drivers needed for older BJT-based systems. This reduces component cost, complexity, and system size.

The Operational Advantage: Beyond Direct Costs

The financial impact of IGBTs extends beyond the bill of materials and energy consumption, influencing overall productivity and product quality.

Enhanced Control and Quality

The ability of IGBTs to operate at high switching frequencies allows for exceptionally fast and precise control over the power delivered to the melt.

This leads to stable and accurate temperature management, which is critical for producing high-quality alloys with a consistent composition, especially in demanding industries like aerospace and medical. The result is less material waste and a higher-value output.

Improved Reliability and Uptime

A simpler system with fewer components is inherently more reliable. By eliminating snubber circuits and simplifying drivers, an IGBT-based furnace has fewer points of failure.

Furthermore, IGBTs maintain stable performance across a wide temperature range, contributing to consistent operation and reducing downtime for maintenance and repairs—a significant indirect cost saving.

Understanding the Complete Picture

While highly advantageous, no technology is without its considerations. A successful implementation requires a holistic understanding.

Sensitivity to Over-Voltage

While IGBTs handle switching stresses well, they are still sensitive to voltage spikes that exceed their maximum rating. Proper system design and protection against external grid-side surges remain critical for ensuring a long service life.

The Importance of the Gate Driver

The gate driver circuit, while simpler, is the brain of the operation. Its proper design is absolutely essential for achieving optimal efficiency, protecting the IGBT from damage, and preventing catastrophic failure modes.

System-Level Optimization

The IGBT module is the powerful engine, but the control system is the driver. Modern systems increasingly use advanced analytics, sometimes involving AI, to analyze operational data. These systems can optimize energy schedules and enable predictive maintenance, maximizing the cost-saving potential that IGBT technology provides.

Making the Right Choice for Your Operation

Choosing the right power electronics is a strategic decision that impacts both immediate and long-term costs.

- If your primary focus is minimizing upfront capital cost (CapEx): The simplified architecture from eliminating snubber circuits and requiring less complex drivers makes IGBT-based systems a compelling choice.

- If your primary focus is reducing long-term operational cost (OpEx): The high energy efficiency of IGBTs directly translates to lower electricity bills and reduced cooling requirements over the furnace's lifetime.

- If your primary focus is product quality and process control: The high switching frequency of IGBTs enables precise temperature management, leading to less material waste and a more consistent, higher-value final product.

Ultimately, adopting IGBT technology is not just an upgrade; it is a fundamental step toward a more efficient, reliable, and profitable melting operation.

Summary Table:

| Aspect | IGBT Contribution | Cost Impact |

|---|---|---|

| Energy Efficiency | High switching efficiency, low power dissipation | Reduces electricity bills (OpEx) |

| System Design | Eliminates snubber circuits, simplifies drivers | Lowers initial investment (CapEx) |

| Operational Control | Precise temperature management via high-frequency switching | Improves product quality, reduces waste |

| Reliability | Fewer components, stable performance across temperatures | Minimizes downtime and maintenance costs |

Ready to optimize your melting process with advanced IGBT technology?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

By integrating efficient IGBT modules, our furnaces deliver significant cost savings through superior energy efficiency, simplified design, and enhanced operational control—directly reducing your capital and operational expenditures.

Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and profitability!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the key features and benefits of a Vacuum Induction Melting Furnace? Achieve High-Purity Metal Production

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys