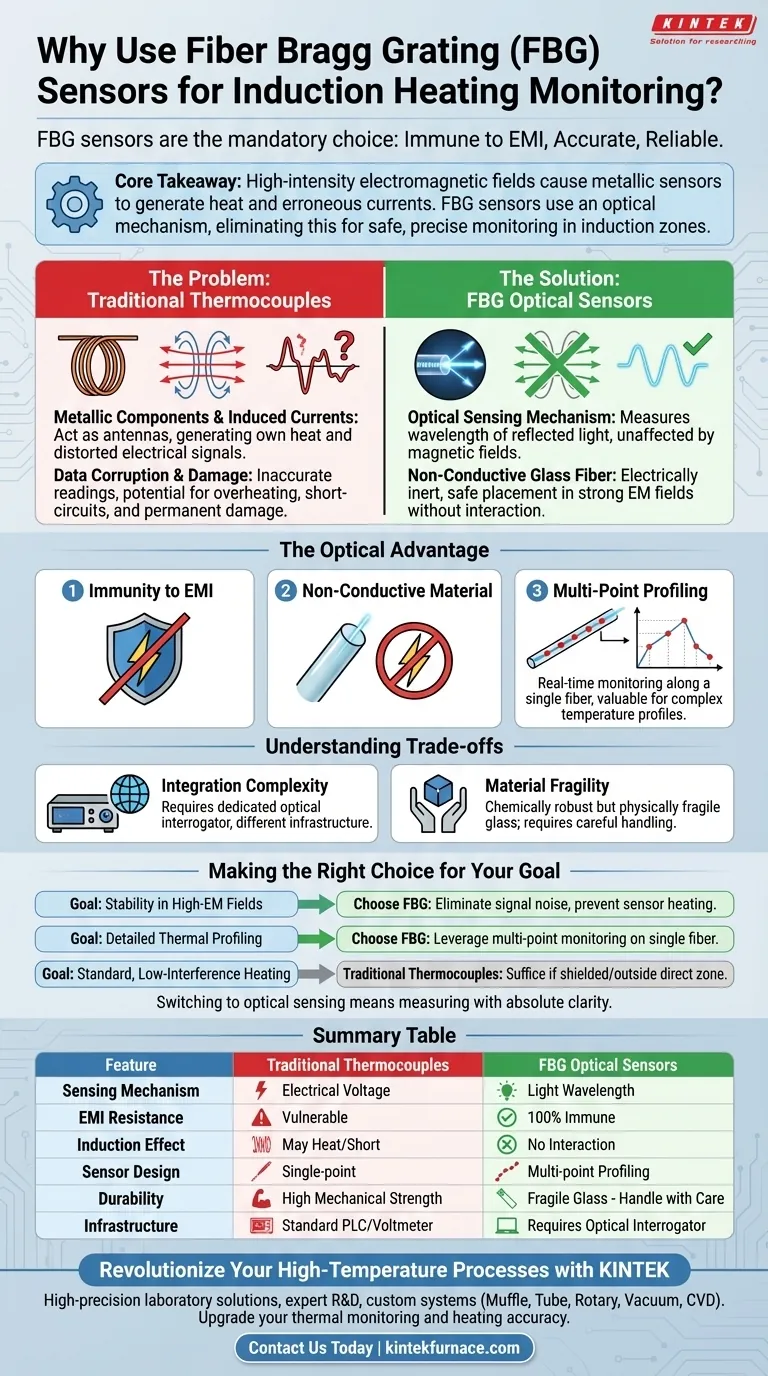

Fiber Bragg Grating (FBG) sensors are the mandatory choice for induction heating environments because they are completely immune to electromagnetic interference (EMI). While traditional thermocouples rely on metal components that react to magnetic fields, FBG sensors utilize light traveling through non-conductive glass fibers to provide accurate temperature data without signal distortion or physical failure.

Core Takeaway High-intensity alternating electromagnetic fields cause metallic sensors to generate their own heat and erroneous electrical currents. FBG sensors eliminate this failure mode by using an optical sensing mechanism, allowing for safe, precise monitoring directly inside the induction zone.

The Problem with Traditional Thermocouples

The Physics of Interference

Induction heating operates by generating high-intensity alternating electromagnetic fields. Traditional thermocouples are constructed from metal wires designed to generate a small voltage based on temperature.

Induced Currents

Because they are metallic, thermocouples essentially act as antennas within the induction coil. The alternating magnetic field creates induced currents directly within the thermocouple wires.

Data Corruption and Damage

These induced currents distort the voltage signal, leading to wildly inaccurate temperature readings. In severe scenarios, the induced current can cause the sensor itself to overheat or short-circuit, resulting in permanent sensor damage.

The Optical Advantage of FBG Sensors

Immunity to EMI

FBG sensors operate on an optical sensing mechanism, measuring changes in the wavelength of reflected light rather than changes in voltage. Light is unaffected by magnetic fields, rendering FBG sensors completely immune to the interference that cripples electronic sensors.

Non-Conductive Material

These sensors are constructed from glass fiber, which is an electrically non-conductive material. This allows the sensor to be placed safely in the center of strong magnetic fields without interacting with the energy source or altering the heating profile.

Multi-Point Profiling

Beyond simple durability, FBG technology allows for real-time, multi-point monitoring along a single fiber. This is particularly valuable in complex applications, such as ammonia decomposition reactors, where understanding the full temperature profile is critical for process control.

Understanding the Trade-offs

Integration Complexity

While FBG sensors solve the interference problem, they require an optical interrogator to interpret the light signals. This is a different infrastructure requirement compared to the standard voltmeters or PLCs used with thermocouples.

Material Fragility

While chemically robust, the glass fiber construction is physically different from metal wire. Proper handling and installation techniques are required to ensure the fiber is not snapped or stressed mechanically during setup in the reactor.

Making the Right Choice for Your Goal

- If your primary focus is stability in high-EM fields: Choose FBG sensors to eliminate signal noise and prevent the sensor from becoming a heating element itself.

- If your primary focus is detailed thermal profiling: Choose FBG sensors to leverage their ability to measure multiple points along a single fiber without complex wiring harnesses.

- If your primary focus is standard, low-interference heating: Traditional thermocouples may suffice, provided they are shielded or located outside the direct induction zone.

By switching to optical sensing, you move from inferring temperature through noise to measuring it with absolute clarity.

Summary Table:

| Feature | Traditional Thermocouples | FBG Optical Sensors |

|---|---|---|

| Sensing Mechanism | Electrical Voltage (Metallic) | Light Wavelength (Glass) |

| EMI Resistance | Vulnerable to signal distortion | 100% Immune to interference |

| Induction Effect | May heat up or short-circuit | No interaction with magnetic fields |

| Sensor Design | Single-point monitoring | Real-time, multi-point profiling |

| Durability | High mechanical strength | Fragile glass (requires careful handling) |

| Infrastructure | Standard PLC/Voltmeter | Requires Optical Interrogator |

Revolutionize Your High-Temperature Processes with KINTEK

Don't let signal noise compromise your critical thermal data. KINTEK provides high-precision laboratory solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique induction or thermal processing needs.

Ready to upgrade your thermal monitoring and heating accuracy? Contact us today to discover how our advanced systems and optical sensing expertise can optimize your research and production outcomes.

Visual Guide

References

- Débora de Figueiredo Luiz, Jurriaan Boon. Use of a 3D Workpiece to Inductively Heat an Ammonia Cracking Reactor. DOI: 10.3390/suschem6040043

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- What are the key industries that utilize vacuum induction melting furnaces? Essential for Aerospace, Medical, and Electronics

- How is the high volatility of Samarium managed during vacuum melting? Expert Burn-off Compensation Strategies

- What is the purpose of an induction furnace? Achieve Superior Metal Melting with Precision & Purity

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a Vacuum Induction Melting (VIM) furnace in Ni-W-Co-Ta alloy prep? Ensure High Purity and Precision

- What is the function of a vacuum arc melting furnace in Cobalt-based alloy prep? Achieve High Purity & Homogeneity

- In which industries is the IGBT induction melting machine commonly used? Key Applications & Benefits