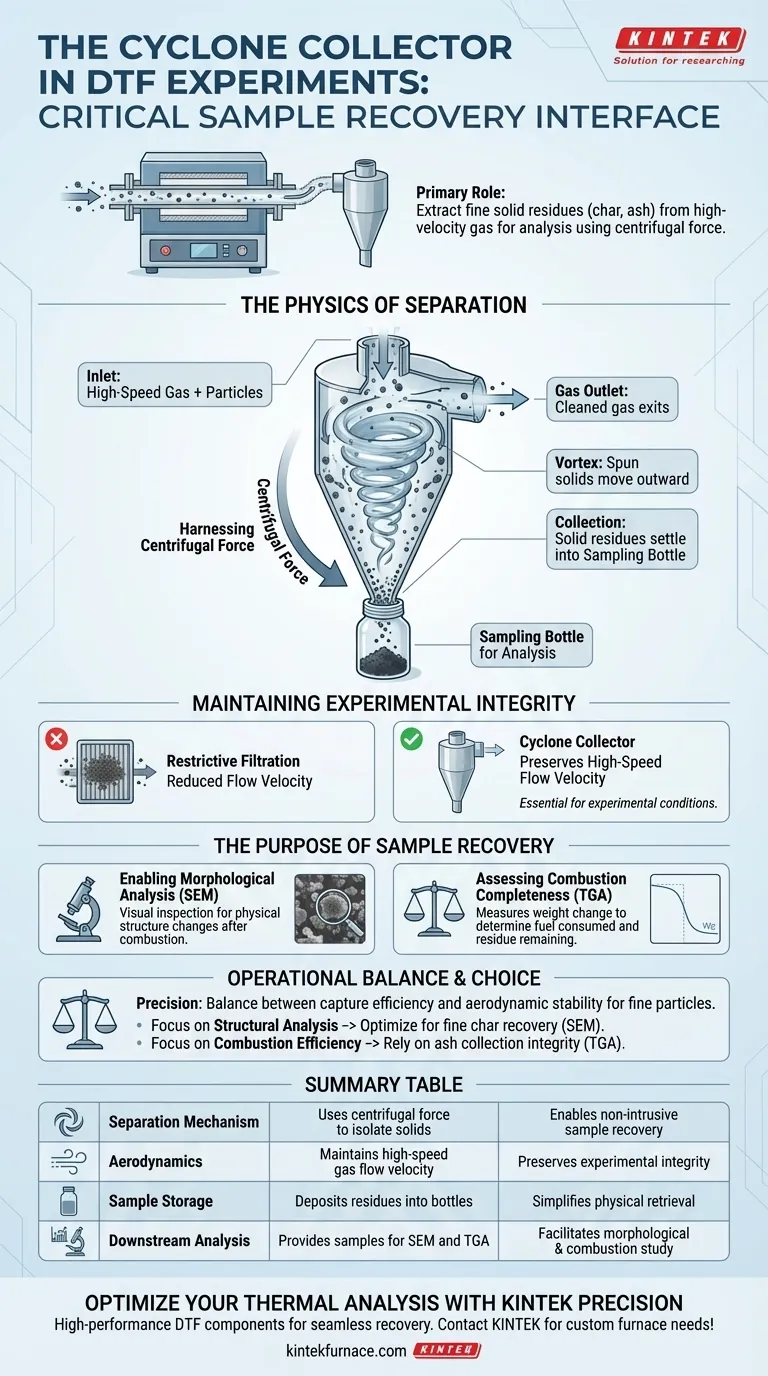

A Cyclone Collector serves as the critical separation interface in Drop Tube Furnace (DTF) experiments. Its primary role is to extract fine solid residues—specifically char and ash—from a high-velocity gas stream using centrifugal force, depositing them into a sampling bottle for analysis.

By leveraging centrifugal force, the Cyclone Collector isolates solid samples from a high-speed gas stream without disrupting the flow velocity. This preservation of flow dynamics is essential for maintaining experimental integrity while recovering materials for microscopic and thermal analysis.

The Physics of Separation

Harnessing Centrifugal Force

In a DTF experiment, materials are transported through the furnace via a high-speed air stream. To recover these materials, the Cyclone Collector utilizes centrifugal force.

This force pushes the heavier solid particles outward against the collector walls. This effectively separates fine char particles and ash from the lighter gas stream.

Collection into Sampling Bottles

Once separated from the gas, the solid residues settle into a designated sampling bottle. This allows for the physical retrieval of the material once the experiment is concluded.

Maintaining Experimental Integrity

Preserving Flow Velocity

One of the most critical aspects of the Cyclone Collector is its impact on aerodynamics. Unlike restrictive filtration methods, this device operates without significantly reducing flow velocity.

This feature is vital. It ensures that the act of sampling does not alter the high-speed conditions required for the experiment itself.

The Purpose of Sample Recovery

Enabling Morphological Analysis

The recovery of these solids is the first step in post-experiment analysis. The collected char and ash are used for Scanning Electron Microscopy (SEM).

SEM allows researchers to perform morphological analysis. This visual inspection reveals changes in the physical structure of the particles after passing through the furnace.

Assessing Combustion Completeness

Beyond structure, the chemical state of the sample is analyzed using Thermogravimetric Analysis (TGA).

TGA measures the weight change of the material during heating. This data is essential for assessing combustion completeness, determining exactly how much fuel was consumed and how much residue remains.

Understanding the Operational Balance

The Need for Precision

The Cyclone Collector represents a balance between capture efficiency and aerodynamic stability. It allows for the extraction of physical evidence (ash and char) from a dynamic system.

However, the reliance on centrifugal force implies that the separation is purely physical. The system is specifically designed to handle fine particles within a high-speed stream, meaning the efficiency of collection is tightly coupled with the velocity of the gas.

Making the Right Choice for Your Goal

The Cyclone Collector acts as the bridge between the dynamic combustion process and static laboratory analysis.

- If your primary focus is Structural Analysis: Ensure the collector is functioning optimally to recover enough fine char for detailed SEM imaging.

- If your primary focus is Combustion Efficiency: Rely on the integrity of the ash collection to provide accurate mass data for TGA assessment.

The Cyclone Collector ultimately transforms a high-speed thermal event into measurable, actionable data.

Summary Table:

| Feature | Function in DTF Experiments | Benefit for Researchers |

|---|---|---|

| Separation Mechanism | Uses centrifugal force to isolate solids from gas | Enables non-intrusive sample recovery |

| Aerodynamics | Maintains high-speed gas flow velocity | Preserves experimental integrity and conditions |

| Sample Storage | Deposits residues into dedicated sampling bottles | Simplifies physical retrieval for lab testing |

| Downstream Analysis | Provides samples for SEM and TGA | Facilitates morphological and combustion study |

Optimize Your Thermal Analysis with KINTEK Precision

Ready to elevate your research accuracy? KINTEK provides high-performance Drop Tube Furnace components designed for seamless sample recovery and analysis. Backed by expert R&D and manufacturing, we offer specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements.

Improve your experimental outcomes today—Contact our specialists at KINTEK to discuss your custom furnace needs!

Visual Guide

References

- Eurig W. Jones, Peter J. Holliman. Pyrolysis-GCMS of Plastic and Paper Waste as Alternative Blast Furnace Reductants. DOI: 10.3390/chemengineering9010015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is it necessary to evacuate and seal quartz tubes for NiPS3 crystals? Master CVT Precision & Purity

- What role does a high-temperature tube furnace play in Bi-MOF transformation? Mastering Nanocomposite Synthesis

- What is the necessity of using a Tube Furnace for phosphorus-doped carbon nanofiber films? Ensure Anaerobic Precision

- What role does a high-temperature tube furnace play in the preparation of biomimetic composite skeletons?

- How does a tube furnace facilitate the conversion of ZIF67/MXene into CoS@C/MXene? Mastering Thermal Synthesis

- What role does a single-zone tube furnace play in the synthesis of (100)-oriented MoO2 nanobelts? Precision APCVD Control

- What is the function of a tube furnace and nitrogen flow in biomass carbonization? Unlock Superior Bio-Carbon Quality

- How does the direct annealing process in a tube furnace affect iridium-based inverse opals? Expert Insights