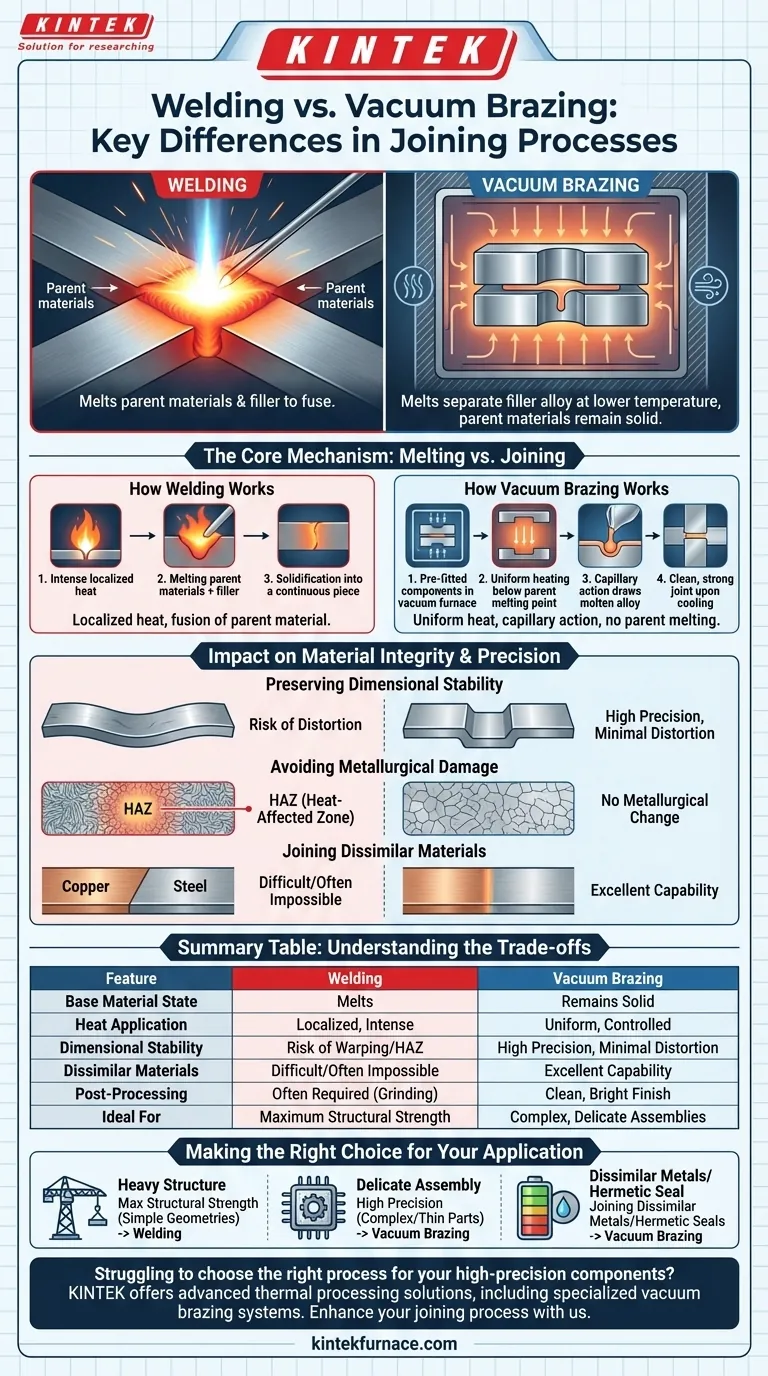

The fundamental difference between welding and vacuum brazing lies in their effect on the base materials being joined. Welding melts the parent materials, often along with a filler, to fuse them into a single piece. In contrast, vacuum brazing uses a separate filler metal (the brazing alloy) that melts at a lower temperature, joining the components while the parent materials themselves remain entirely solid.

While both processes create strong joints, they serve fundamentally different engineering goals. Welding is about creating a monolithic structure through fusion, while vacuum brazing is about assembling precise components without altering their original form or properties.

The Core Mechanism: Melting vs. Joining

The choice between welding and brazing is dictated by how the heat is applied and its effect on the components. This distinction is the source of all subsequent advantages and disadvantages.

How Welding Works

Welding uses an intense, localized heat source (like an electric arc or flame) to melt the edges of the parent materials. This molten pool, often mixed with a filler rod, solidifies to form a single, continuous piece. The joint is effectively part of the parent material itself.

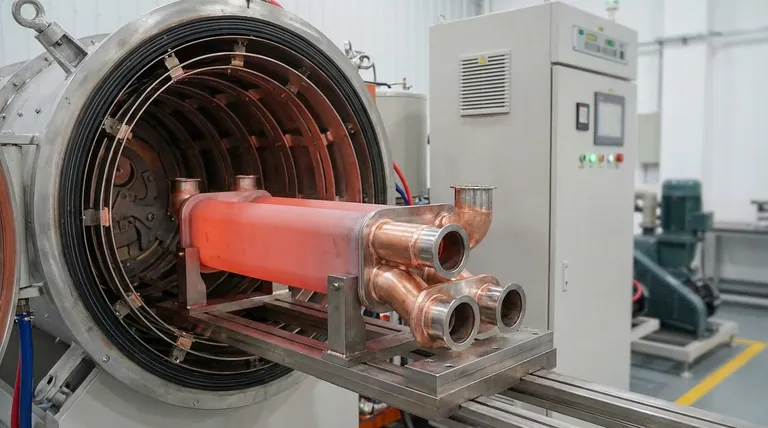

How Vacuum Brazing Works

Vacuum brazing involves placing pre-fitted components, with a brazing alloy applied to the joints, into a vacuum furnace. The entire assembly is heated uniformly to a temperature above the alloy's melting point but below the parent materials' melting point. The molten alloy is drawn into the tight gaps via capillary action and, upon cooling, solidifies to form a strong, clean joint.

Impact on Material Integrity and Precision

Because vacuum brazing does not melt the base materials, it preserves the integrity of the components in ways that welding cannot. This makes it ideal for high-precision applications.

Preserving Dimensional Stability

The intense, localized heat of welding creates significant thermal stress, which can lead to warping and dimensional distortion. Vacuum brazing heats the entire assembly slowly and uniformly in a controlled environment, which minimizes internal stresses and ensures the final product retains its precise shape and tolerances.

Avoiding Metallurgical Damage

Welding creates a heat-affected zone (HAZ) in the area surrounding the weld. In this zone, the parent material's microstructure and mechanical properties are altered, which can sometimes weaken it. Vacuum brazing's lower, uniform temperatures leave the parent materials' metallurgical characteristics completely unchanged.

Joining Dissimilar Materials

Vacuum brazing excels at joining materials with different properties, such as copper to stainless steel. Because the base materials don't melt, issues of metallurgical incompatibility are avoided. Welding dissimilar metals is often extremely difficult or impossible.

Understanding the Trade-offs

Neither process is universally superior; they are tools designed for different tasks. Understanding their limitations is key to making the correct engineering choice.

Joint Strength vs. Part Complexity

A properly executed weld becomes an integral part of the parent material, typically offering superior tensile and fatigue strength. This makes it ideal for heavy structural applications. Brazed joints are extremely strong but are generally better suited for complex assemblies where maintaining the integrity of delicate components is the priority.

Process Environment

Welding is a versatile process that can often be performed in a variety of settings. Vacuum brazing is a furnace-based process, meaning it requires specialized equipment and is performed in batches. This makes it less portable but highly repeatable and controllable.

Post-Processing and Finish

Welded joints almost always require secondary operations like grinding and cleaning to remove slag and spatter. By contrast, parts that exit a vacuum furnace are clean, bright, and free from discoloration, often requiring no further finishing.

Making the Right Choice for Your Application

Selecting the correct process requires a clear understanding of your project's most critical requirement.

- If your primary focus is maximum structural strength for simple geometries: Welding provides a robust, monolithic joint ideal for load-bearing applications.

- If your primary focus is joining complex, delicate, or thin-walled parts with high precision: Vacuum brazing is the superior choice for maintaining dimensional stability and material integrity.

- If your primary focus is joining dissimilar metals or creating hermetic seals: Vacuum brazing provides a clean and reliable solution where welding would likely fail.

Ultimately, choosing between these two processes is about selecting the tool that best respects your materials and achieves your final engineering goal.

Summary Table:

| Feature | Welding | Vacuum Brazing |

|---|---|---|

| Base Material State | Melts | Remains Solid |

| Heat Application | Localized, Intense | Uniform, Controlled |

| Dimensional Stability | Risk of Warping/HAZ | High Precision, Minimal Distortion |

| Dissimilar Materials | Difficult/Often Impossible | Excellent Capability |

| Post-Processing | Often Required (Grinding) | Clean, Bright Finish |

| Ideal For | Maximum Structural Strength | Complex, Delicate Assemblies |

Struggling to choose the right process for your high-precision components?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal processing solutions. Our expertise in high-temperature furnaces, including specialized vacuum brazing systems, ensures your complex assemblies are joined with precision, preserving material integrity and dimensional stability.

Let our deep customization capabilities meet your unique requirements. Contact KINTEK today to discuss how our vacuum furnace solutions can enhance your joining process.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity