Fundamentally, quartz tubes are transparent to a broad spectrum of light, including ultraviolet (UV), visible, and infrared (IR) wavelengths. This wide transmission window, unlike that of standard glass, allows them to be used in processes that rely on high-energy UV radiation for sterilization or curing, as well as those that use IR radiation for heating.

While many materials transmit visible light, quartz's unique ability to also transmit both UV and IR radiation, combined with its exceptional thermal and chemical stability, makes it an indispensable material for a wide range of demanding scientific and industrial processes.

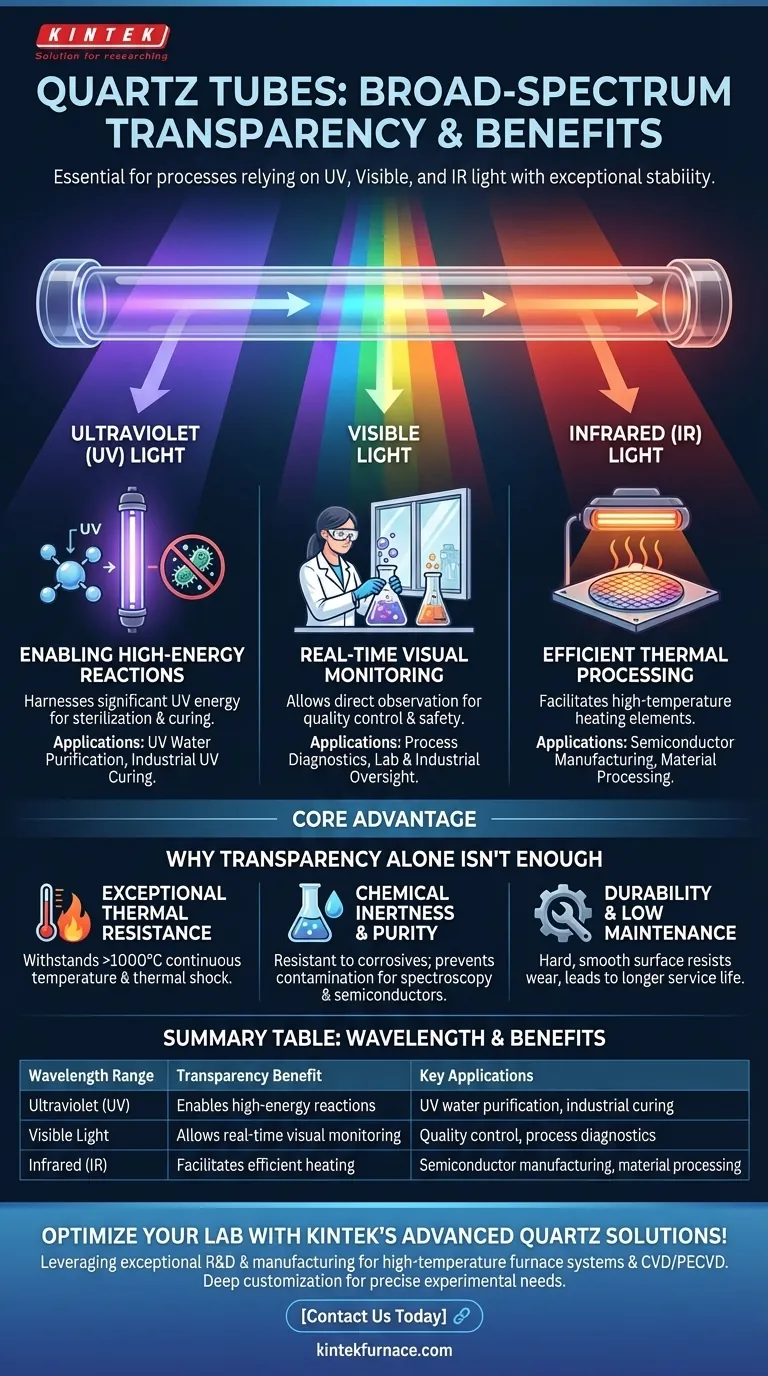

The Core Advantage: Broad-Spectrum Transparency

The primary benefit of quartz is its ability to allow different forms of energy, in the form of light, to pass through it with minimal absorption. This is critical for applications where the light itself is the tool.

Transmitting Ultraviolet (UV) Light

UV light carries significant energy, which is harnessed for specific reactions. Quartz tubes are essential for containing these processes without blocking the critical UV wavelengths.

Common applications include UV water purification, where UV-C light deactivates pathogens, and industrial UV curing for inks, coatings, and adhesives.

Transmitting Visible Light

Transparency to visible light allows for direct, real-time visual monitoring of a process. This is invaluable for quality control, process diagnostics, and safety in both laboratory and industrial settings.

You can observe reactions, check for contamination, or monitor fluid levels without interrupting the operation or compromising the internal environment.

Transmitting Infrared (IR) Light

Infrared radiation is essentially heat. Quartz's ability to transmit IR makes it an ideal material for applications involving high-temperature heating elements or thermal processing.

IR lamps can be placed outside a quartz tube to heat the contents inside efficiently, as the tube itself does not block the thermal energy. This is common in semiconductor manufacturing and other material processing tasks.

Why Transparency Alone Isn't Enough

If transparency were the only factor, cheaper materials might suffice. The true value of quartz lies in the combination of its optical properties with its robust physical and chemical characteristics.

Exceptional Thermal Resistance

Many processes that use UV or IR lamps generate extreme heat. Quartz can withstand continuous operating temperatures over 1000°C and endure severe thermal shock without cracking. Standard glass would fail under these conditions.

Chemical Inertness and Purity

Quartz is highly resistant to acids, water, and other corrosive agents. This ensures that the tube itself does not react with or contaminate the chemicals being processed inside.

This purity is critical in spectroscopy, where any leaching from the container would interfere with measurements, and in semiconductor manufacturing, where even trace contaminants can ruin a product.

Durability and Low Maintenance

The hard, smooth surface of a quartz tube resists wear and minimizes the buildup of residue from the materials inside. This leads to longer service life, less frequent cleaning, and reduced operational downtime.

Understanding the Trade-offs

No material is perfect for every situation. Being aware of the limitations of quartz is key to making an informed decision.

Material Purity Dictates Performance

Not all quartz is the same. The term often refers to fused quartz (made from natural crystals) or fused silica (synthetically produced). The presence of trace impurities, particularly in natural fused quartz, can slightly reduce UV transmission.

For deep-UV applications, high-purity synthetic fused silica is often required, as it offers the best transparency in that part of the spectrum.

Cost Considerations

Quartz is significantly more expensive than borosilicate glass (like Pyrex). If your application does not require UV/IR transparency or extreme thermal resistance, a more conventional type of glass may be a more cost-effective choice.

Mechanical Fragility

While thermally and chemically robust, quartz is still a type of glass. It is brittle and can shatter from mechanical shock or impact. Care must be taken during handling and installation to avoid breakage.

Making the Right Choice for Your Application

Selecting the correct material requires balancing performance needs with budget constraints.

- If your primary focus is UV-based processes: Quartz is often the only practical choice due to its high UV transmission and resistance to degradation from high-energy radiation.

- If your primary focus is high-temperature heating: Quartz's ability to transmit IR energy and withstand extreme thermal shock makes it superior to standard glass.

- If your primary focus is simple visual monitoring at low temperatures: A more cost-effective material like borosilicate glass or even certain polymers may be sufficient for your needs.

By understanding this interplay of optical, thermal, and chemical properties, you can confidently select the right material for your specific technical challenge.

Summary Table:

| Wavelength Range | Transparency Benefit | Key Applications |

|---|---|---|

| Ultraviolet (UV) | Enables high-energy reactions | UV water purification, industrial curing |

| Visible Light | Allows real-time visual monitoring | Quality control, process diagnostics |

| Infrared (IR) | Facilitates efficient heating | Semiconductor manufacturing, material processing |

Optimize your lab with KINTEK's advanced quartz tube solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our quartz tubes can benefit your UV, visible, or IR applications!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment