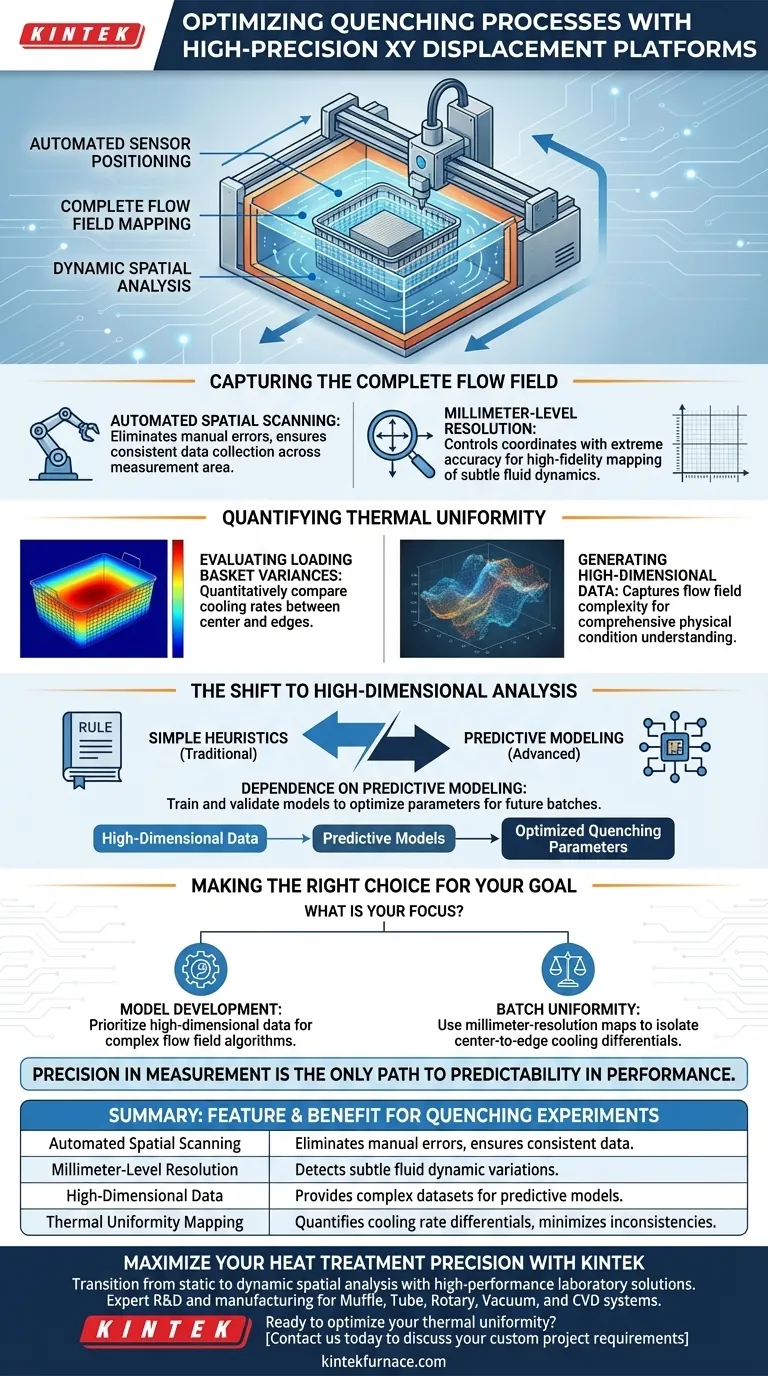

A high-precision XY displacement platform functions as the automated backbone for advanced sensor positioning within simulated quenching chambers. By systematically moving measurement sensors through preset windows, it generates complete, high-resolution cross-section maps of the flow field. This technology replaces static, single-point measurements with a dynamic, spatial analysis of the cooling environment.

The platform's ability to provide millimeter-level resolution reveals critical cooling discrepancies between the center and edges of a loading basket. This granular data is the prerequisite for building accurate predictive models and fine-tuning quenching parameters.

Capturing the Complete Flow Field

To optimize heat treatment, you must move beyond measuring a single point and understand the entire environment.

Automated Spatial Scanning

The platform operates by carrying measurement sensors through specific, pre-determined windows in the chamber.

This automation eliminates manual positioning errors. It ensures that data is collected consistently across the defined measurement area.

Millimeter-Level Resolution

The primary advantage of this system is its ability to control spatial coordinates with extreme accuracy.

This results in flow field maps with millimeter-level resolution. Such high-fidelity mapping is necessary to detect subtle variations in fluid dynamics that macro-level measurements often miss.

Quantifying Thermal Uniformity

The data collected by the XY platform is specifically used to evaluate how different areas of a workload experience cooling.

Evaluating Loading Basket Variances

A major challenge in quenching is non-uniform cooling across the workload.

The platform allows for a quantitative comparison between different positions, such as the center of a loading basket versus its edges. Identifying these gradients is the first step toward correcting them.

Generating High-Dimensional Data

The output is not merely a set of temperatures, but a high-dimensional experimental dataset.

This data captures the complexity of the flow field. It provides a comprehensive picture of the physical conditions interacting with the metal during the quench.

The Shift to High-Dimensional Analysis

While this technology offers superior insight, it changes the nature of data analysis required for optimization.

Moving Beyond Simple Heuristics

Traditional methods may rely on general rules of thumb for quenching adjustments.

The high-precision platform, however, provides complex data that demands sophisticated interpretation. The value of the platform is fully realized only when this data is fed into predictive models.

Dependence on Predictive Modeling

The ultimate utility of the platform lies in its contribution to model development.

The high-dimensional data is used to train and validate predictive models. These models are what ultimately allow engineers to optimize quenching parameters for future batches.

Making the Right Choice for Your Goal

To effectively utilize a high-precision XY displacement platform, consider your specific optimization targets.

- If your primary focus is Model Development: Prioritize the platform's ability to generate high-dimensional data to train your predictive algorithms for complex flow fields.

- If your primary focus is Batch Uniformity: Use the millimeter-resolution maps to specifically isolate and quantify the cooling rate differential between the center and the edges of your loading basket.

Precision in measurement is the only path to predictability in performance.

Summary Table:

| Feature | Benefit for Quenching Experiments |

|---|---|

| Automated Spatial Scanning | Eliminates manual positioning errors and ensures consistent data collection. |

| Millimeter-Level Resolution | Detects subtle fluid dynamic variations between center and edge positions. |

| High-Dimensional Data | Provides the complex datasets required for training accurate predictive models. |

| Thermal Uniformity Mapping | Quantifies cooling rate differentials to minimize batch-to-batch inconsistencies. |

Maximize Your Heat Treatment Precision with KINTEK

Transition from static measurements to dynamic spatial analysis with high-performance laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of specialized equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet your unique experimental needs.

Whether you are refining quenching parameters or developing advanced predictive models, our precision-engineered high-temperature furnaces and accessories provide the reliability your research demands.

Ready to optimize your thermal uniformity? Contact us today to discuss your custom project requirements!

Visual Guide

References

- Artificial Intelligence Modeling of the Heterogeneous Gas Quenching Process for Steel Batches Based on Numerical Simulations and Experiments. DOI: 10.3390/dynamics4020023

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why is temperature stability important in vacuum furnace operations? Ensure Precise Heat Treatment for Superior Materials

- Why does the surface of steel appear bright after vacuum hardening? Discover the Secret to Flawless Finishes

- Why is a segmented PID control system necessary for lithium battery vacuum drying? Ensure Precision & Safety

- What precautions should be taken when handling samples in a vacuum furnace? Ensure Safety and Precision in Your Lab

- What is the advantage of computer-controlled processes in vacuum furnaces? Achieve Perfect Repeatability for High-Performance Applications

- How do vacuum brazing furnaces eliminate part distortion? Achieve Perfect Dimensional Accuracy

- Why are vacuum furnaces important for stainless steel processing? Ensure Corrosion Resistance and Pristine Finishes

- What are the key requirements for a vacuum tempering furnace's cooling system? Ensure Precise Control for Superior Metallurgical Results