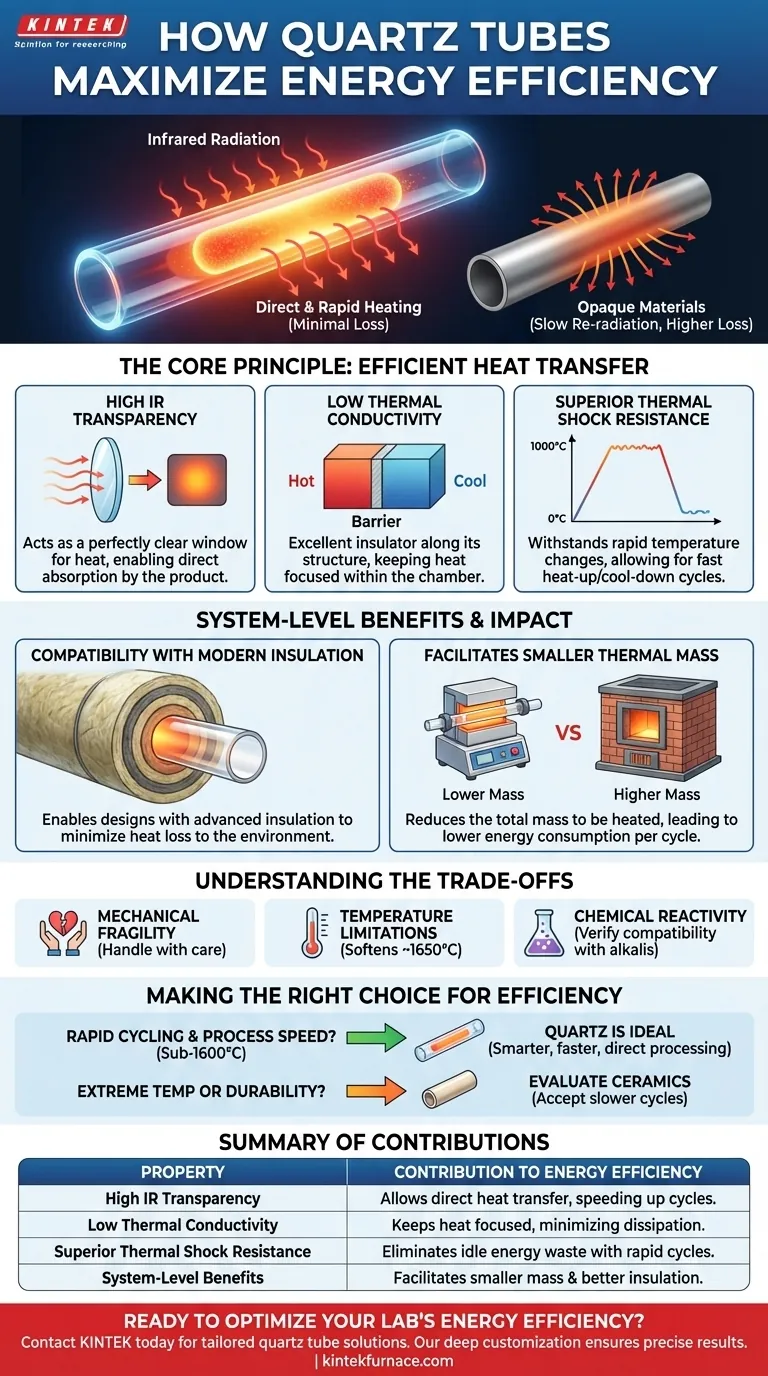

At its core, a quartz tube's contribution to energy efficiency stems from its unique thermal properties, which allow for more direct and rapid heating of a target material. Unlike metals or opaque ceramics that block and slowly re-radiate thermal energy, quartz is highly transparent to infrared radiation, letting heat pass through it to do its work with minimal loss. This allows for faster processing cycles and significantly reduces the energy wasted heating the chamber itself.

The true value of quartz in energy efficiency is not simply about retaining heat, but about its ability to transmit heat directly and withstand rapid temperature changes. This enables faster, on-demand thermal processes that eliminate the enormous energy waste associated with slow, continuous heating cycles.

The Core Principle: Efficient Heat Transfer

The efficiency of a quartz tube is not about being a better insulator in the traditional sense. It's about fundamentally changing how thermal energy is delivered to a workpiece.

High Infrared (IR) Transparency

This is the single most important property. Fused quartz is exceptionally transparent to a wide spectrum of infrared radiation, which is the primary mechanism of heat transfer in many high-temperature processes.

Think of it as a perfectly clear window for heat. Energy from a heating element can pass directly through the quartz wall and be absorbed by the product inside, leading to rapid and efficient heating.

Metals or opaque ceramics, by contrast, must first absorb the heat, get hot themselves, and then slowly re-radiate that heat to the product. This two-step process is slower and inherently less efficient.

Low Thermal Conductivity

While it lets radiant heat pass through, quartz is a poor conductor of heat along its physical structure. This means it acts as an excellent insulator, preventing heat from escaping the system.

This property ensures that the heat energy remains focused within the processing chamber rather than dissipating out through the ends or support structures of the tube.

Superior Thermal Shock Resistance

Quartz has an extremely low coefficient of thermal expansion. It can be heated to over 1000°C and cooled rapidly without cracking.

This allows for extremely fast heat-up and cool-down cycles. A furnace can be brought to temperature in minutes, not hours, and shut down just as quickly, eliminating the massive energy consumption required to keep conventional furnaces idling between batches.

How Quartz Enables System-Level Efficiency

A quartz tube's intrinsic properties also allow engineers to design more efficient overall furnace and reactor systems around it. It is an enabling component.

Compatibility with Modern Insulation

Because quartz effectively contains the process environment, designers can build systems with advanced insulation right up against the tube.

Features like high-quality polycrystalline mullite fiber, double-layer shells, and sophisticated air-cooling jackets work in concert with the quartz tube to minimize thermal loss to the surrounding environment.

Facilitating a Smaller Thermal Mass

Since quartz enables direct heating of the product, the entire furnace system can be designed with a much lower thermal mass. You are no longer required to heat tons of dense refractory brick just to process a few kilograms of material.

This reduction in the total mass that needs to be heated directly translates to lower energy consumption per cycle.

Understanding the Trade-offs

No material is perfect for every application. Objectivity requires acknowledging the limitations of quartz.

Mechanical Fragility

Quartz is a type of glass and is inherently brittle. It cannot withstand mechanical shock or impact and requires careful handling and system design to prevent breakage.

Temperature Limitations

While excellent for many processes, fused quartz begins to soften at temperatures around 1650°C (3000°F). For applications requiring higher temperatures, advanced ceramics like alumina may be a more suitable choice, though often at the cost of IR transparency.

Chemical Reactivity

Under certain high-temperature conditions, quartz can react with alkaline materials. The chemical compatibility of your specific process must be verified to ensure the longevity of the tube.

Making the Right Choice for Your Goal

Selecting the right material requires aligning its properties with your primary operational objective.

- If your primary focus is rapid cycling and process speed: Quartz is the ideal choice due to its high IR transparency and unmatched thermal shock resistance.

- If your primary focus is maximum energy efficiency in sub-1600°C processes: The ability of quartz to enable on-demand, direct heating makes it a superior option for minimizing operational costs.

- If your primary focus is extreme temperature (above 1650°C) or high physical durability: You should evaluate advanced ceramics, accepting the trade-off of slower, less direct heating cycles.

Ultimately, choosing quartz is a decision to enable smarter, faster, and more direct thermal processing.

Summary Table:

| Property | Contribution to Energy Efficiency |

|---|---|

| High IR Transparency | Allows direct heat transfer to materials, reducing energy loss and speeding up cycles |

| Low Thermal Conductivity | Acts as an insulator, keeping heat focused in the chamber to minimize dissipation |

| Superior Thermal Shock Resistance | Enables rapid heating and cooling, eliminating idle energy waste |

| System-Level Benefits | Facilitates smaller thermal mass and better insulation for overall efficiency |

Ready to optimize your lab's energy efficiency with advanced quartz tube solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnaces like Tube Furnaces, tailored for diverse laboratories. Our deep customization capabilities ensure precise solutions for your unique experimental needs. Contact us today to discuss how our products can reduce your energy costs and enhance performance!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role do tube furnaces play in semiconductor and battery production? Unlock Precision in High-Temp Processing

- How to clean a tube furnace? A Step-by-Step Guide to Safe and Effective Maintenance

- Why is a high-precision vacuum tube furnace essential for CVD graphene? Master Growth Control & Purity

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control